Wire Cut Wire is gaining traction in various industries. The global market for wire products is expected to grow at a rate of 4% annually, reaching over $25 billion by 2025. This growth highlights the increasing importance of materials like Wire Cut Wire in manufacturing and construction.

When utilizing Wire Cut Wire, precision is key. High-quality wire ensures reliability in applications such as electronics and automotive production. However, the choice of wire can be overwhelming. Many projects suffer from improper material selection. This mistake can lead to structural weaknesses or production delays. Attention to detail in choosing Wire Cut Wire can mitigate these risks.

In summary, the effective use of Wire Cut Wire in your projects is crucial. Understanding the specific needs and applications can enhance project outcomes. Investing time in research can yield long-term benefits. Aim for quality to avoid common pitfalls associated with inferior materials.

Wire cut wire, often referred to as “high-precision wire,” plays a significant role in various industries. This type of wire is engineered through a meticulous process to achieve specific dimensions and performance characteristics. According to industry reports, the demand for wire cut wire has increased by approximately 15% annually, driven by its applications in electronics, automotive, and aerospace sectors.

One key application of wire cut wire is in the production of high-precision components. For instance, manufacturers utilize it for creating intricate shapes and parts that require a tight tolerance. The wire’s ability to retain shape and resist deformation under stress is crucial. However, it is essential to select the right material for the intended application. Sometimes, this preference might lead to unnecessary costs if not evaluated correctly.

Quality control is another major concern. Although wire cut wire can facilitate detailed work, imperfections can arise during the cutting and handling processes. These flaws might affect the final product's functionality. Regular audits and quality checks are essential but can be overlooked, leading to potential setbacks in production timelines. Balancing cost, quality, and performance is not always straightforward. Awareness and careful planning are vital in ensuring the successful use of wire cut wire in projects.

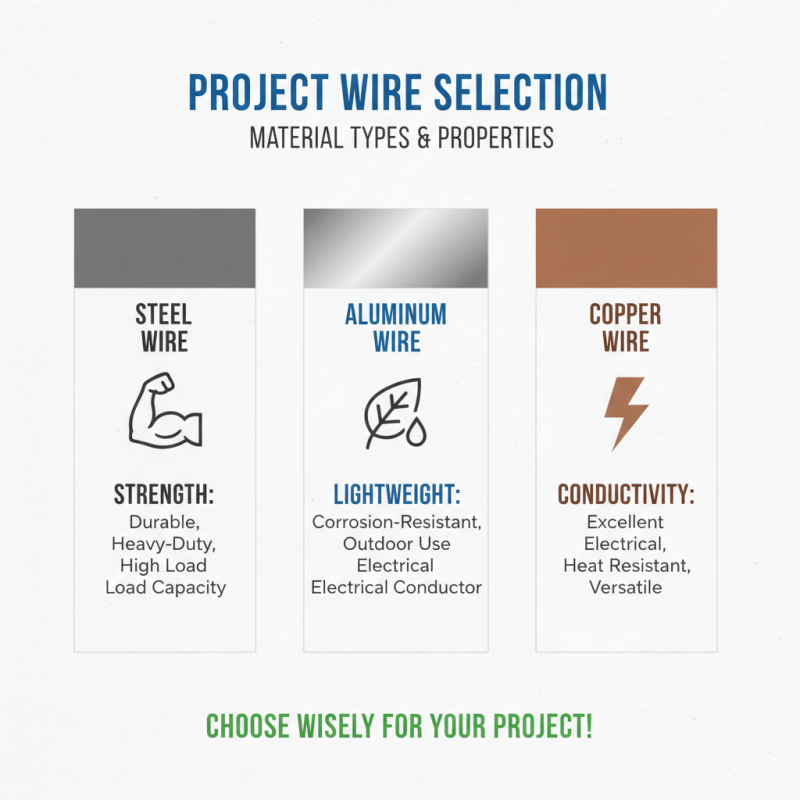

When selecting wire cut wire for your project, it's crucial to consider material types. Wire can be made from different elements like steel, aluminum, or copper. Each type has unique properties. For instance, steel wire is strong and durable, making it ideal for heavy-duty applications. On the other hand, aluminum is lightweight and resistant to corrosion, suitable for outdoor projects.

You also need to think about diameter and length. Thinner wires bend easily but may not support heavy objects. Conversely, thicker wires provide strength but can be difficult to work with. Often, the project’s purpose should dictate your choice. For instance, a decorative piece might require finer wire, while structural components need sturdier options.

Remember, wire cut wire isn't all about functionality. There are aesthetic elements to consider too. Color and finish may impact design appeal. A shiny metal wire could enhance visual interest, while a matte finish might blend better in certain contexts. Ultimately, reflecting on these aspects can guide you in selecting the best wire for your project.

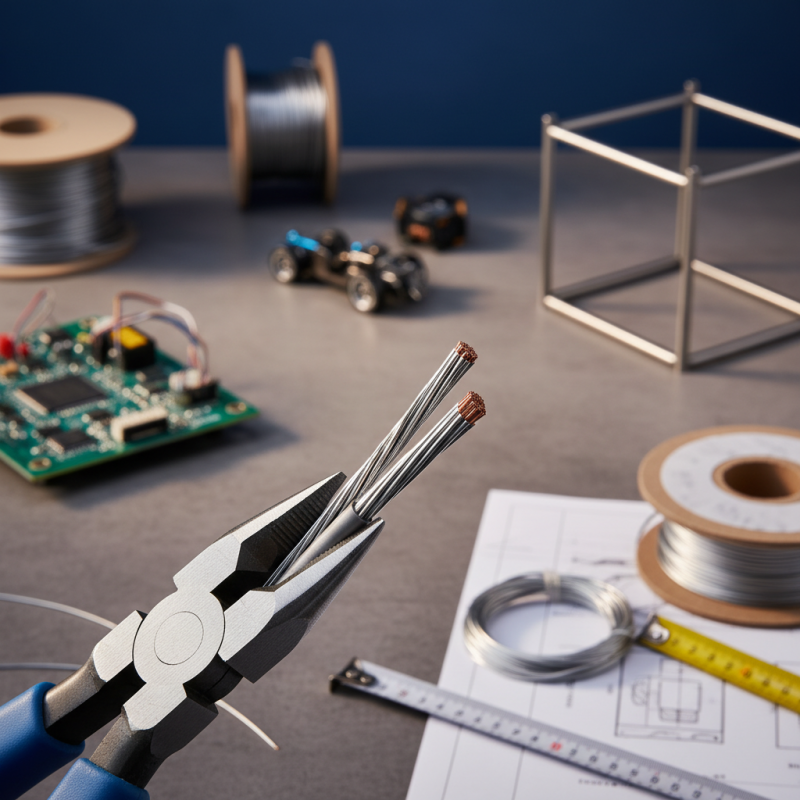

When working with cut wire, having the right tools makes a difference. A good pair of wire cutters is essential. They help create clean edges and avoid fraying. Flat-nose pliers can grip the wire firmly. They are perfect for bending or twisting. A ruler or measuring tape ensures accuracy in your projects. You want to measure twice to avoid mistakes. A cutting mat protects your workspace too.

Don't forget to consider additional materials. Wire connectors can join pieces without soldering. Electrical tape secures wires neatly in place. If you're using a heavy gauge, solder might be necessary. Accidental short circuits can be frustrating. You might find glue helpful for certain types of projects.

It's okay to make mistakes along the way. Sometimes, a bend doesn’t go as planned. You might over-cut a wire length. These moments are learning opportunities. Practice can improve your technique over time. Stay patient and focused as you refine your skills. Embrace the process of creation and experimentation.

Cutting and shaping wire can seem intimidating. However, with a step-by-step approach, it becomes manageable. Begin by selecting your wire. Choose the appropriate gauge based on your project's requirements. Thicker wire is sturdier but harder to manipulate. On the other hand, thinner wire is flexible but may not hold heavy weights.

Next, measure and mark your wire. Use a ruler for accuracy. A simple mistake here could lead to pieces that are too short or too long. Take your time and double-check the measurements. Once satisfied, use wire cutters to snip the wire. Aim for a clean cut to avoid sharp edges. Burrs can develop, and addressing them is vital for safety.

Shaping the wire is another crucial step. Use pliers to bend and twist as needed. Practice makes perfect here. It can be frustrating at times. You may need to redo certain bends. Embrace this process as part of your learning journey. Be patient with yourself; mistakes can lead to unique designs.

When working with wire cut wire, safety is crucial. Reports indicate that improper handling accounts for over 30% of job-related injuries in the construction sector. Personal protective equipment (PPE) is essential. Use gloves to protect your hands from sharp ends. Safety goggles can prevent eye injuries from flying particles. Neglecting these precautions can lead to serious accidents.

Keep your workspace organized. Clutter can increase the risk of slips and falls. A study shows that nearly 25% of workplace injuries result from such hazards. Ensure that tools are within reach, but not in the way. Regular maintenance of tools is equally important. Dull tools can slip and cause injuries. Staying aware of your surroundings also helps. Always communicate clearly with your team. This will reduce misunderstandings that lead to accidents.

Be mindful of the materials you use. Some wires can have sharp edges or splinters. Dispose of damaged wires properly to prevent injuries to anyone in the area. Reflect on previous projects and learn from past mistakes. Safety is not just a guideline; it’s a necessity that shapes the success of your work environment.

| Project Type | Wire Cut Wire Size (AWG) | Recommended Tools | Safety Precautions | Common Applications |

|---|---|---|---|---|

| Craft Projects | 20 AWG | Wire Cutters, Pliers | Wear safety goggles; Work in a well-ventilated area | Jewelry making, small sculptures |

| Electrical Projects | 18 AWG | Wire Strippers, Insulation Tape | Disconnect power source before working; Use insulated tools | Wiring circuits, connecting devices |

| Home Improvement | 14 AWG | Screwdriver, Wire Connectors | Ensure proper grounding; Avoid overloading circuits | Installing lights, outlets |

| Model Making | 22 AWG | Cutting Mat, Craft Knife | Use caution with sharp tools; Work slowly and carefully | Scale models, dioramas |