In the ever-evolving landscape of manufacturing, the integration of advanced technologies and materials is crucial for maintaining competitive advantage. One significant innovation that has garnered attention is the use of Mould Inserts. According to a recent report by MarketsandMarkets, the global tooling market is projected to reach USD 250 billion by 2025, driven by the increasing need for precision and efficiency in production processes. Mould Inserts, in particular, are redefining standards in manufacturing by allowing for intricate designs, enhanced durability, and reduced lead times. These components not only contribute to improved product quality but also offer significant cost savings through reduced waste and enhanced production speed. As manufacturers look for ways to optimize their processes, understanding the unmatched benefits of Mould Inserts becomes essential for leveraging their full potential in various applications.

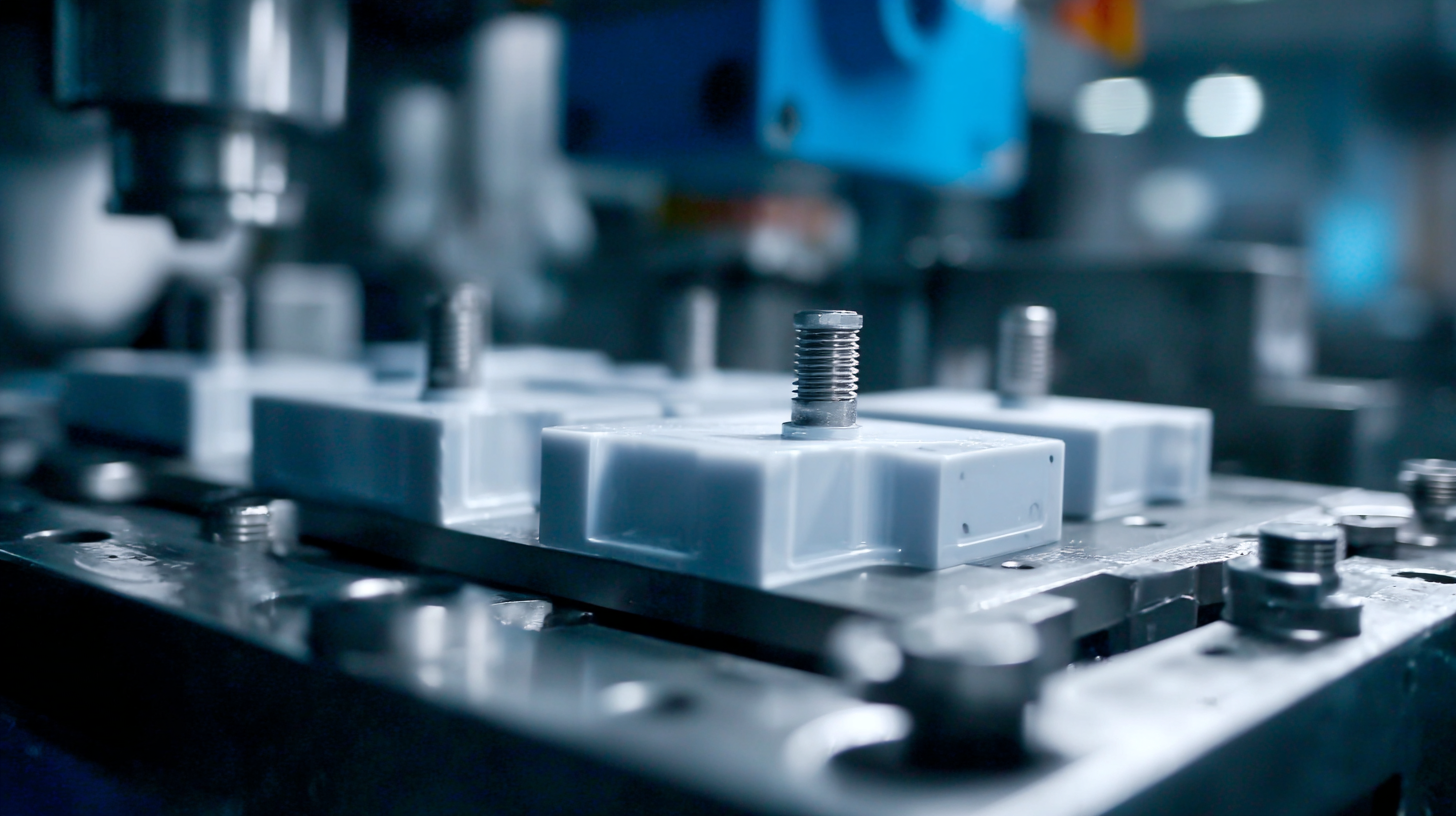

Mould inserts play a crucial role in enhancing precision within manufacturing processes. These components allow for the creation of complex shapes and designs that would be challenging to achieve with standard moulds. By utilizing mould inserts, manufacturers can optimize production efficiency, reducing the need for extensive reworking or adjustments, which ultimately saves time and resources.

Moreover, mould inserts significantly improve product quality. They ensure consistent dimensions and surface finishes, which are vital for maintaining high standards in manufacturing. This reliability fosters greater customer satisfaction, as the end products are not only aesthetically pleasing but also functionally superior. The adaptability of mould inserts allows manufacturers to easily switch designs without overhauling entire moulds, making them an invaluable asset in a fast-paced industry where customization and speed are essential.

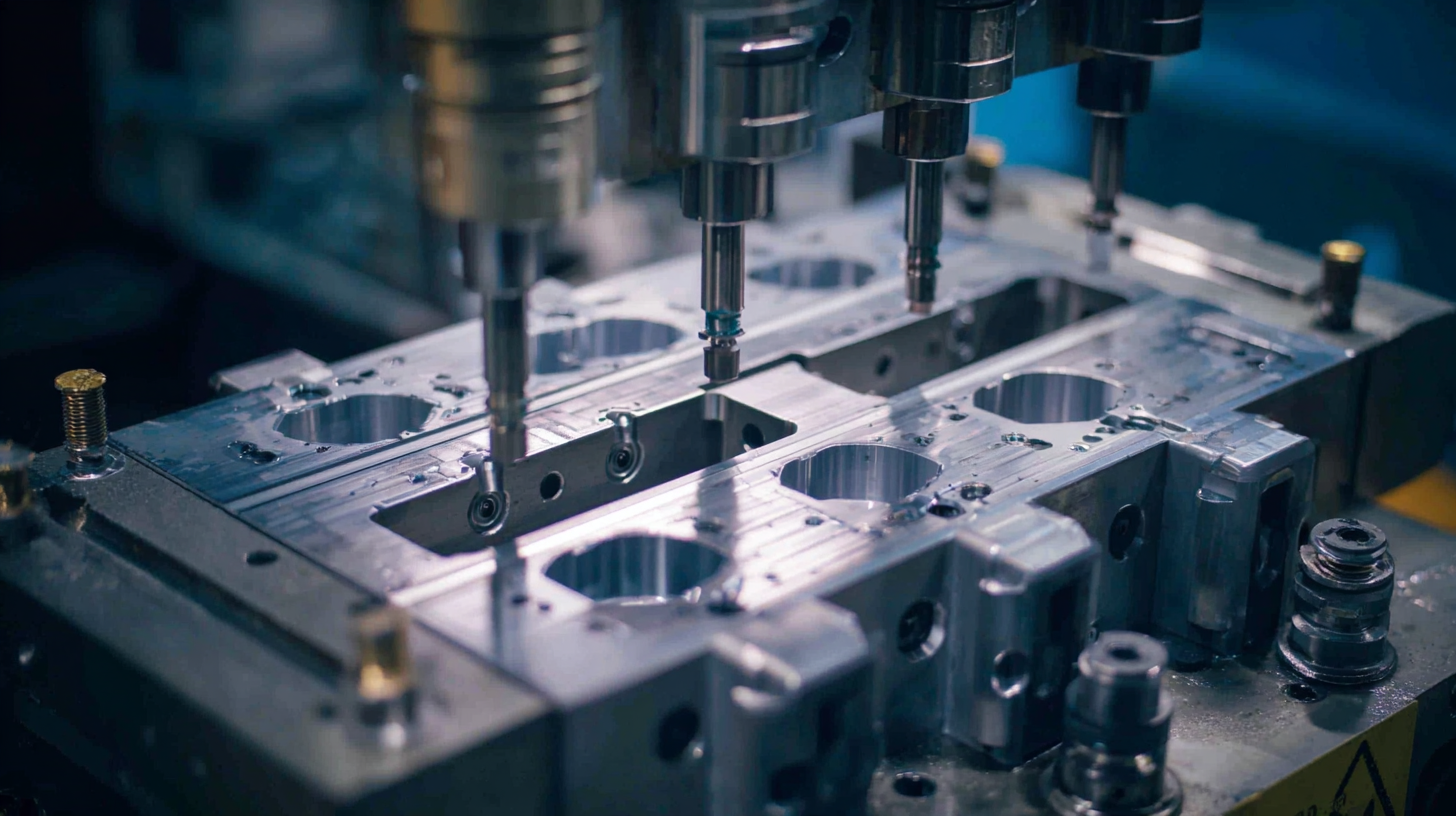

Mould inserts have become an essential component in modern manufacturing, particularly due to their cost efficiency. According to a report by the Plastic Industry Association, the use of mould inserts can lead to a reduction in production costs by up to 30%. This is largely attributable to their ability to optimize material usage and minimize waste. Traditional mould production often requires significant amounts of raw material and time; however, with mould inserts, manufacturers can achieve complex geometries that were previously cost-prohibitive.

Additionally, mould inserts significantly reduce machinery wear and downtime, further lowering operational expenses. A study published in the Journal of Manufacturing Science and Engineering suggests that the implementation of mould inserts can reduce the cycle time by as much as 25%, which translates to increased productivity. This efficiency not only enhances the quality of the final products but also allows companies to allocate resources more effectively, thereby driving down overall manufacturing costs. As industries increasingly shift towards sustainable practices, the financial and operational advantages of mould inserts make them a strategic choice for competitive manufacturing.

This chart illustrates the cost efficiency gained by using mould inserts in manufacturing, highlighting the reduction in production expenses across different operational stages.

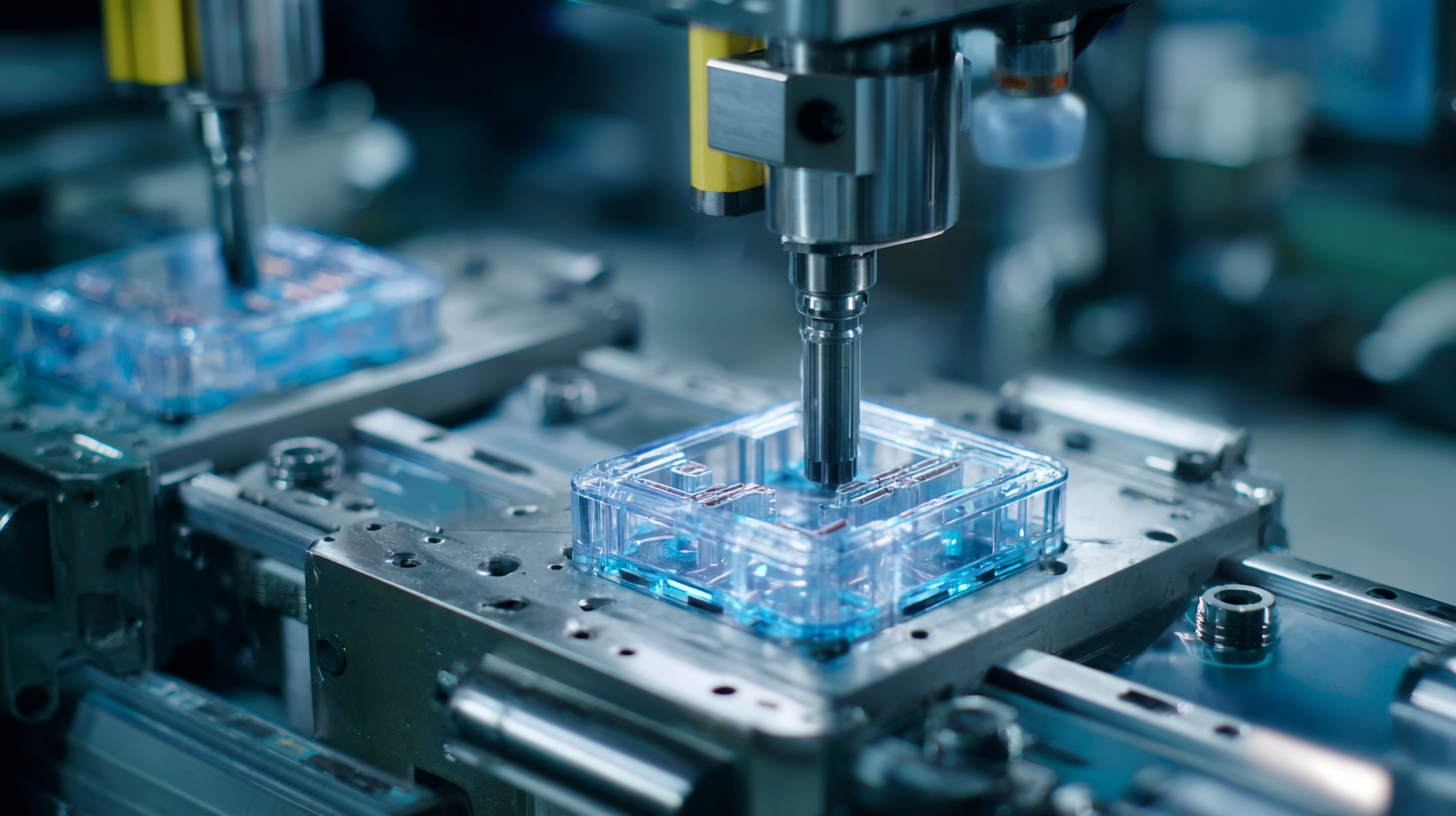

The use of mould inserts in manufacturing processes has revolutionized the way products are designed and produced. One of the most significant advantages is the improvement in product quality. Mould inserts ensure that each component produced meets stringent specifications by providing a consistent and reliable design framework. This consistency reduces variations in size, shape, and finish that can affect the overall quality of the final product.

The use of mould inserts in manufacturing processes has revolutionized the way products are designed and produced. One of the most significant advantages is the improvement in product quality. Mould inserts ensure that each component produced meets stringent specifications by providing a consistent and reliable design framework. This consistency reduces variations in size, shape, and finish that can affect the overall quality of the final product.

Furthermore, mould inserts facilitate more efficient production cycles, allowing manufacturers to achieve higher precision in their designs. By utilizing these inserts, companies can minimize the risk of defects, leading to a significant decrease in waste and rework costs. As a result, businesses not only enhance their product offerings but also build a stronger reputation in the market due to the reliability and durability of their products. The integration of mould inserts ultimately leads to improved customer satisfaction, reinforcing the critical role they play in modern manufacturing.

Mould inserts present a unique opportunity for manufacturers to enhance flexibility and customization in their production processes. By allowing for quick adjustments, these inserts can be tailored to meet specific requirements of various projects. This adaptability not only reduces lead times but also minimizes material waste, making the production process more efficient and environmentally friendly.

Furthermore, mould inserts enable manufacturers to experiment with different designs and shapes without the need to replace entire moulds. This capability is particularly beneficial for industries where product variation is frequent. By customizing mould inserts according to the desired specifications, manufacturers can quickly respond to market demands and innovate their product lines. This level of customization empowers businesses to stay competitive and cater to diverse consumer preferences, ultimately driving growth and success in their sectors.

| Benefit | Description | Flexibility Level | Customization Options |

|---|---|---|---|

| Cost Efficiency | Mould inserts can significantly reduce manufacturing costs by allowing for the reuse of moulds. | High | Various shapes and sizes to adapt to different products |

| Improved Production Speed | Inserts can speed up the production process by simplifying the moulding cycle. | Medium | Adjustable configurations for various production tasks |

| Enhanced Quality Control | Allows for better precision and less waste in the manufacturing process. | High | Custom measurement tolerances for different materials |

| Diverse Applications | Mould inserts can be used across various industries, from automotive to consumer goods. | Very High | Tailored designs for specific industry requirements |

| Sustainability | Using mould inserts reduces material waste and contributes to more sustainable manufacturing practices. | Medium | Options for eco-friendly materials and processes |

When it comes to enhancing the durability of manufacturing processes, investing in mould inserts stands out as a key strategy. According to a 2022 report by the Association for Manufacturing Technology, companies that have integrated advanced mould inserts into their production lines have seen a 25% increase in tool life and a 20% reduction in maintenance costs. This remarkable durability translates to fewer downtime incidents, allowing manufacturers to maintain continuous production cycles and meet market demands more effectively.

Incorporating mould inserts not only boosts longevity but also improves the quality of the final product. A study by the Society of Plastic Engineers highlighted that mould inserts can enhance precision and consistency in production, with a reported increase in first-pass yield rates by up to 30%. This capability is crucial in a competitive market where quality directly influences customer satisfaction and brand reputation.

Tips: To maximize the benefits of mould inserts, consider selecting materials best suited for your specific application, such as hardened steel or aluminum for increased wear resistance. Additionally, regular maintenance of mould systems can further extend the life of inserts, ensuring that your manufacturing operations remain efficient and cost-effective. Lastly, keep abreast of advancements in mould technology, as innovations can provide new opportunities for durability and performance enhancements.