Wire Cut techniques are essential for anyone working with wires. These methods enhance precision and efficiency in various applications. Whether you’re a novice or an expert, mastering different Wire Cut techniques can elevate your skills.

The versatility of Wire Cut techniques is impressive. Each technique serves a unique purpose. Some techniques focus on reliability, while others emphasize speed. There’s a spectrum of methods that cater to different needs. Sometimes, it’s easy to overlook a simpler method. This could lead to unnecessary complications.

Exploring Wire Cut techniques means recognizing both strengths and weaknesses. Understanding your tools can sometimes feel overwhelming. It's essential to practice and refine your approach. Mistakes are part of the learning curve. Embrace them, and keep striving for improvement.

Wire cutting is a crucial skill in various industries. Understanding the different techniques enhances efficiency in your projects. The global wire cutting market was valued at approximately $2.5 billion in 2022, showcasing its importance. Rapid advancements in technology continue to influence these methods.

When considering wire cutting, grasp a few fundamental techniques. For instance, abrasive wire cutting uses high-speed wire and abrasive particles to slice through materials seamlessly. Another method, laser wire cutting, provides precision for complex shapes. These techniques reflect the diverse needs of industries like aerospace and automotive.

Tip: Always check the wire type before cutting. The wrong wire may lead to inaccurate results. Additionally, employ safety features on your equipment. These steps can prevent accidents and ensure smoother operations.

It's essential to reflect on your skills regularly. Many professionals overlook the need for continuous learning. Workshops and training sessions can improve your techniques. Remember, the wire-cutting landscape evolves. Embrace new ideas and keep pushing your boundaries.

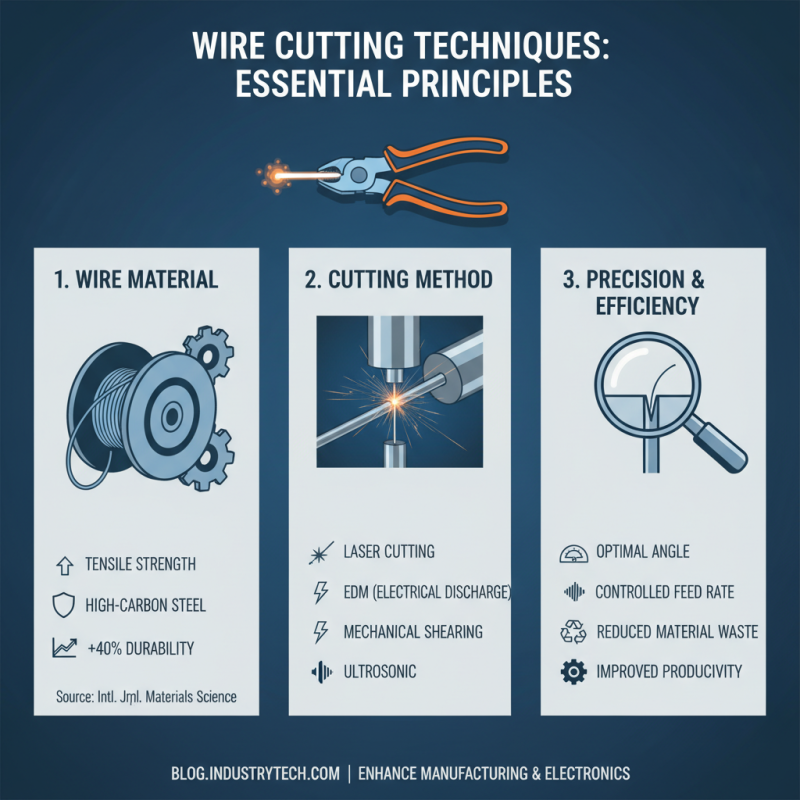

Wire cutting techniques are essential in various industries, from manufacturing to electronics. Understanding the key principles of these techniques can significantly enhance efficiency and precision. One fundamental aspect is the choice of wire material. Different materials boast different tensile strengths. For example, a report from the International Journal of Materials Science found that using high-carbon steel wires can improve durability by 40% compared to standard wire options.

Another critical principle is the cutting method. Techniques such as electro-discharge machining (EDM) and laser cutting vary in precision and application. The American Society of Mechanical Engineers highlights that EDM can achieve tolerances as tight as 0.001 inches. This level of precision makes it suitable for intricate designs. However, the high operational cost of EDM might not be suitable for all projects.

Moreover, wire tension plays a crucial role in the cutting process. Too much tension can lead to wire breakage or poor cut quality, while too little may result in uneven cuts. Continuous monitoring is necessary, yet many operators overlook this step. A study by the Manufacturing Institute reveals that over 30% of production errors stem from improper tension management. Understanding these principles helps refine techniques but requires ongoing reflection and adjustment in practice.

Wire cutting techniques are vital in various industries. These methods are crucial for precision and efficiency. Each technique has its unique applications and benefits.

One classic method is the wire EDM. This technique uses electrical discharges to cut through hard materials. It's popular in aerospace and automotive sectors. However, it can be slow for larger projects. Another common technique is laser wire cutting. This uses high-intensity beams to sever materials rapidly. It offers high precision and minimal thermal distortion. Yet, the initial investment for laser systems can be high.

Mechanical wire cutting is another option. This technique employs physical cutters to split materials. It's simpler but may not achieve the precision needed in some industries. Furthermore, there’s a need for regular maintenance, which can be a hassle. As industries evolve, so do wire cutting methods. Continuous improvement is essential. Many companies struggle to keep up with new technologies. They risk falling behind if they don’t adapt. Each technique comes with its challenges and reflections on efficiency and cost-effectiveness.

Wire cutting techniques are evolving rapidly to meet high standards in precision and efficiency. Advanced methods, such as laser and water jet cutting, are gaining traction. According to a recent industry report, the global market for advanced wire cutting techniques is projected to grow at a CAGR of 5.6% between 2023 and 2028. This growth highlights the increasing demand for accurate and efficient cutting solutions across various sectors.

Efficiency is key in wire cutting. Techniques such as CNC (Computer Numerical Control) wire cutting have revolutionized production processes. With speeds surpassing traditional methods, CNC cutting minimizes waste. However, not all iterations of these technologies yield positive results. Inconsistent machine calibration can lead to inaccuracies that affect final products. A study showed that nearly 18% of manufacturers faced quality issues due to poor technique implementation.

Precision matters in industries that require tight tolerances. Techniques like EDM (Electrical Discharge Machining) are crucial for achieving desired specifications. Despite advancements, many operators still struggle with mastering these complex methodologies. A survey indicated that about 30% of operators reported needing additional training. Continuous improvement is essential to fully harness the benefits of advanced wire cutting methods and ensure optimal performance.

| Technique | Description | Benefits | Applications |

|---|---|---|---|

| Laser Cutting | Utilizes a high-powered laser to cut through materials. | High precision and minimal material waste. | Metal fabrication, electronics, and automotive parts. |

| Water Jet Cutting | Uses a high-pressure jet of water with abrasives to cut various materials. | No heat-affected zone, can cut thick materials. | Stone, glass, metals, and composites. |

| Plasma Cutting | Employs a plasma torch to melt and cut through metal. | Fast cutting speed and cost-effective for thick metals. | Steel fabrication and ductwork. |

| Wire EDM | Electrical Discharge Machining using a thin wire electrode. | Extremely precise cuts for intricate designs. | Tool and die manufacturing, and complex shapes. |

| Band Saw Cutting | Continuous band of metal teeth passes through the material. | Versatile for various materials and shapes. | Wood and metal cutting in industrial settings. |

| CNC Cutting | Computer Numerical Control machines for precision cutting. | High precision and repeatability. | Woodworking, metal fabrication, and prototypes. |

| Cold Cutting | Non-thermal cutting methods that do not affect material properties. | No thermal deformation and preserves material integrity. | Sensitive materials in electronics and aerospace. |

| Oxy-fuel Cutting | Uses a mixture of oxygen and fuel gas to cut metals. | Cost-effective for thick steel cutting. | Heavy-duty metalwork and construction. |

| Diamond Wire Cutting | Uses a wire saw with diamond segments for cutting hard materials. | Smooth cuts and excellent for hard materials. | Concrete, granite, and other natural stones. |

| Cryogenic Cutting | Utilizes extremely low temperatures to enhance cutting precision. | Reduces tool wear and improves cut quality. | Aerospace and advanced materials applications. |

Wire cutting can be dangerous if not done carefully. Always wear protective gear like gloves and goggles. The right tools matter too. Use sharp, high-quality wire cutters for clean cuts. Dull tools can cause slippage, leading to accidents.

Work in a well-lit area to see what you’re doing. Keep your workspace tidy to avoid tripping or cutting accidents. Ensure the wire is secured properly before cutting. A wobbly wire can snap back and hurt you.

After cutting, inspect the wire ends. Sharp edges can cause cuts, so consider using a file to smooth them. It’s easy to overlook this step, but it’s important. Reflect on your technique and keep practicing to improve.

Different wires may require adjustments in approach. Small mistakes can lead to significant issues. Stay safe and focused.