In the ever-evolving landscape of manufacturing, understanding the various techniques of Machining Cutting is crucial for maintaining competitiveness and efficiency. According to Dr. Ellen Graves, a leading expert in the field of Machining Cutting, "Mastering cutting techniques not only enhances production quality but also significantly reduces operational costs." As manufacturers strive for precision and speed, the significance of employing effective machining practices cannot be overstated.

Machining Cutting encompasses a diverse array of methods that cater to the unique demands of different materials and applications. From traditional techniques like turning and milling to advanced methods such as laser cutting and waterjet cutting, each technique has its distinct advantages and limitations. Awareness of these options enables manufacturers to select the most appropriate process, thereby optimizing their workflows and achieving superior results.

In this article, we will explore the top 10 Machining Cutting techniques that every manufacturer should be familiar with. By grasping these essential methods, businesses can leverage innovative practices to enhance productivity and foster growth in an increasingly competitive market.

Machining is a fundamental process in the manufacturing industry, encompassing a range of techniques used to shape materials into precise parts and components. Defined as the removal of material from a workpiece to achieve desired dimensions and surface finishes, machining plays a critical role in ensuring quality and performance in manufactured goods. According to a report from the American Machinist, the global machining market is expected to exceed $100 billion by 2025, highlighting its significance in driving industrial growth and innovation.

The importance of machining in manufacturing is underscored by its ability to produce complex geometries and maintain tight tolerances, which are vital for industries such as aerospace, automotive, and medical devices. A study by the National Institute of Standards and Technology (NIST) reveals that around 30% of manufacturing costs are attributed to machining processes, emphasizing the need for manufacturers to adopt efficient cutting techniques. By optimizing machining operations, companies can enhance productivity, reduce waste, and improve overall quality, thereby maintaining competitiveness in a rapidly evolving market.

Machining cutting techniques are fundamental processes in manufacturing, allowing for the shaping and finishing of materials to precise specifications. Among the most common methods, turning is a prevalent technique where a cutting tool moves in a linear motion against a rotating workpiece to create cylindrical parts. This method is celebrated for its efficiency in producing components with high accuracy and a smooth finish. Additionally, milling is another essential technique where rotary cutters shape material by removing excess material from a stationary workpiece. This versatile process enables manufacturers to create complex geometries and intricate designs, making it a staple in various industries.

Another important method is drilling, which involves creating holes in a workpiece using a rotating drill bit. This technique is not only vital for producing holes but also for enhancing the functionality of parts by providing clearance for fasteners or for fluid transfer. Alongside these, grinding serves as a crucial finishing process that utilizes an abrasive wheel to refine surface quality and achieve tight tolerances. Understanding these machining techniques equips manufacturers with the essential knowledge to select the appropriate method tailored to their specific production requirements, ultimately driving efficiency and quality in the manufacturing process.

Machining cutting techniques are essential for manufacturers seeking to optimize efficiency and precision in production processes. Understanding these methods allows businesses to select the most suitable technique for their specific applications, which can significantly affect operational costs and product quality. According to a report by the American Society of Mechanical Engineers (ASME), the global market for machining tools is projected to reach $95 billion by 2025, underscoring the critical importance of mastering these techniques.

The five primary cutting techniques—turning, milling, drilling, grinding, and electrical discharge machining (EDM)—each have unique characteristics that can be leveraged based on material types and desired outcomes. For instance, turning is often employed for circular components and is especially effective for achieving tight tolerances, with reports indicating that it can reduce production time by up to 40% when utilized correctly. Similarly, grinding provides superior surface finishes and is commonly employed in the finishing processes of precision parts. Recent studies highlight that 30% of manufacturing defects can be traced back to inadequate cutting processes, making an in-depth understanding of these techniques crucial for maintaining quality assurance in production lines.

This bar chart illustrates the popularity index of the top 10 machining cutting techniques every manufacturer should be familiar with. The popularity index is measured on a scale from 1 to 10, reflecting their usage and importance in modern manufacturing processes.

When it comes to machining cutting techniques, selecting the appropriate method for different materials is crucial for achieving optimal results. For instance, metals, plastics, and composites each require distinct approaches. A report by the Institute for Advanced Manufacturing highlights that improper cutting techniques can increase production costs by up to 30% due to rapid tool wear and subpar surface finishes. Understanding the properties of the materials being worked on can significantly enhance efficiency and product quality.

For metals, high-speed steel and carbide tools are often the go-to choices, especially when machining harder alloys like stainless steel. Techniques like turning and milling are commonly employed, as they allow for precise cuts and the ability to handle varying thicknesses. Conversely, softer materials like plastics might benefit from slower cutting speeds to prevent melting. Cutting methods such as laser and waterjet cutting are highly effective for intricate designs in these materials and can lead to reduced waste while maintaining edge quality.

Tips: When choosing a cutting technique, always consider the material's hardness and thermal properties. For harder materials, opt for quicker machining speeds but use coolant to reduce heat buildup, prolonging tool life. In contrast, when dealing with softer materials, maintaining a steady speed can prevent deformation and ensure a high-quality finish. Adapting your approach based on material characteristics can result in significant time and cost savings in your manufacturing processes.

| Cutting Technique | Material Types | Tool Used | Main Applications | Advantages |

|---|---|---|---|---|

| Turning | Metal, Plastic | Lathe Tool | Cylindrical Parts | High Precision |

| Milling | Metal, Wood | End Mill | Flat and Complex Surfaces | Versatile |

| Drilling | Metal, Composite | Drill Bit | Creating Holes | Straight Holes |

| Grinding | Metal, Ceramic | Grinding Wheel | Finishing Operations | Fine Finish |

| Laser Cutting | Metal, Plastic | Laser | Intricate Designs | Precision Cutting |

| Water Jet Cutting | Metal, Glass | Water Jet | Thick Materials | No Heat Affected Zone |

| Electrical Discharge Machining (EDM) | Metal | EDM Electrode | Complex Shapes | No Mechanical Force |

| Plasma Cutting | Metal | Plasma Torch | Thick Metal Sheets | Fast Cutting |

| Chipless Cutting (Shearing) | Metal, Plastic | Shear Blade | Metal Sheets | Cost-Effective |

| Sawing | Metal, Wood | Saw Blade | Cutting Shapes | Wide Applications |

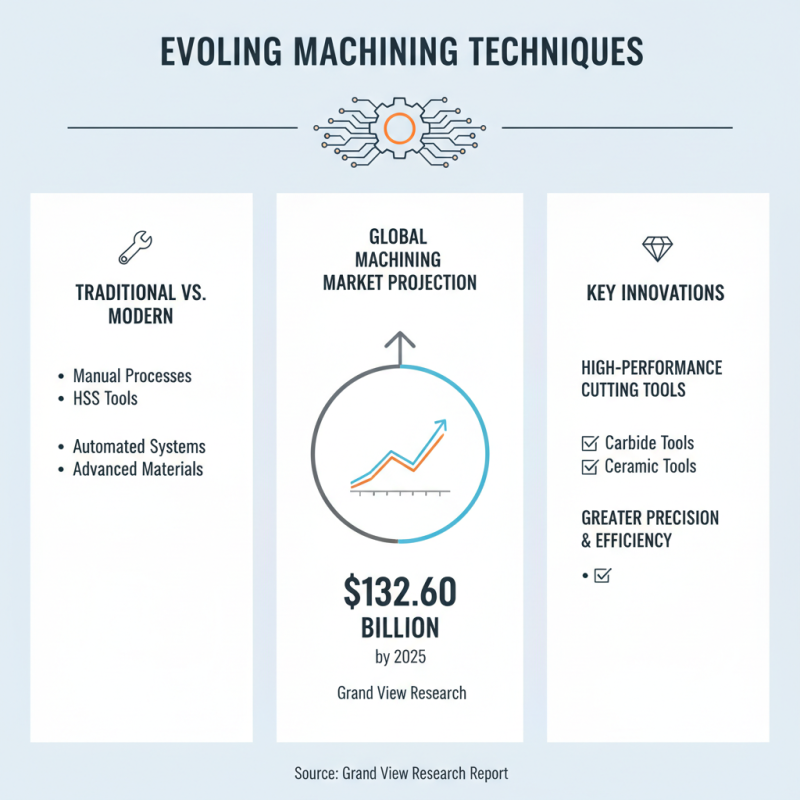

As the manufacturing landscape evolves, so too do the machining cutting techniques adopted by manufacturers. An emerging trend is the integration of advanced materials and automated processes. According to a recent industry report by Grand View Research, the global machining market is projected to reach $132.60 billion by 2025, driven largely by innovations in high-performance cutting tools and materials. For instance, the adoption of carbide and ceramic tools has surged, enabling manufacturers to achieve greater precision and efficiency in their machining operations.

Moreover, digitization and Industry 4.0 technologies are poised to revolutionize cutting techniques. The use of smart sensors and machine learning algorithms can significantly enhance the predictive maintenance of cutting tools, as highlighted in a study by McKinsey & Company. This technology allows manufacturers to optimize their cutting processes in real-time, resulting in reduced wastage and increased productivity. Additionally, additive manufacturing is being integrated with traditional machining processes, creating hybrid techniques that offer unparalleled design flexibility and material efficiency, as per insights from the World Economic Forum. By embracing these future trends, manufacturers can not only improve their operational efficiency but also position themselves competitively in an increasingly demanding market.