In the world of precision metalworking, having the right tools is essential for achieving optimal results. Among these tools, HSS punches stand out for their durability and precision. High-speed steel (HSS) punches are specifically designed to offer excellent performance in various metalworking applications, making them indispensable for professionals and enthusiasts alike. This article will explore the top 10 HSS punches you need to know, highlighting their unique features and advantages.

Whether you are involved in fabricating, machining, or any other form of metalworking, understanding the different types of HSS punches available can significantly enhance your productivity. Each punch offers distinct characteristics that cater to a variety of tasks, from creating clean holes to ensuring accuracy in intricate designs. By delving into the best HSS punches on the market, you can make informed choices that will elevate your work’s quality while maintaining efficiency in your projects. Join us as we guide you through these essential tools that every metalworking professional should consider adding to their toolkit.

High-speed steel (HSS) punches are indispensable tools in precision metalworking due to their superior hardness, wear resistance, and longevity. Essential features of HSS punches include the alloy composition that generally consists of tungsten and molybdenum, contributing to their ability to endure high-impact applications and resist thermal fatigue. According to a report from the International Journal of Advanced Manufacturing Technology, properly engineered HSS punches can maintain their edge for significantly longer than traditional steel punches, reducing the frequency of replacements and downtime in production environments.

Moreover, precision in metalworking hinges on the dimensional accuracy of the punches. High-quality HSS punches can achieve tolerances as tight as ±0.005 inches, making them ideal for intricate components that require exact dimensions. A study by the Institute of Metalworking Technologies highlighted that the adoption of HSS punches in manufacturing operations can yield a 20% increase in overall productivity by minimizing scrap rates. Additionally, the efficient heat treatment processes used in preparing HSS punches ensure that they can withstand the thermal stresses of high-speed operations without warping or losing their cutting edge, thus enhancing operational efficiency.

The geometry of HSS punches is also a critical aspect, influencing their performance in various applications. Features such as precision-ground cutting edges and ergonomic shapes contribute to reduced cutting forces, which not only prolongs the life of the tool but also enhances the quality of the finished product. With the rise of automation in manufacturing, understanding the intricacies of HSS punches is essential for engineers and metalworking professionals aiming to optimize production performance and maintain rigorous quality standards.

This bar chart illustrates the essential features of HSS punches used in precision metalworking, such as diameter, length, material hardness, cost, and durability. These characteristics are crucial for choosing the right punch for specific applications.

When it comes to precision metalworking, selecting the right high-speed steel (HSS) punches is crucial for achieving optimal performance and durability. Several brands have established themselves as leaders in the HSS punch market by consistently delivering high-quality tools that meet the demands of professionals. These brands are renowned for their commitment to precision engineering, ensuring that their punches maintain sharpness and structural integrity over extended use.

One of the key factors that set these top brands apart is their focus on innovation and continuous improvement in design and materials. They utilize advanced manufacturing techniques and high-grade HSS to produce punches that can withstand rigorous applications while providing superior accuracy. Furthermore, many of these brands offer a diverse range of punches tailored to specific tasks, allowing users to select tools that perfectly match their needs, whether for deep draw, hole punching, or intricate metal detailing. The reputable names in the industry not only prioritize performance but also emphasize user safety and comfort, integrating ergonomic features into their products.

| Punch Type | Diameter (mm) | Material | Hardness (HRC) | Application |

|---|---|---|---|---|

| Round Punch | 10 | HSS | 62 | Sheet Metal |

| Square Punch | 12 | HSS | 60 | Material Formation |

| Oblong Punch | 15x8 | HSS | 61 | Hydraulic Press |

| Keyway Punch | 8 | HSS | 62 | Machinery Parts |

| Flower Punch | 9 | HSS | 59 | Decorative Parts |

| Circle Cutting Punch | 20 | HSS | 63 | Sheet Cutting |

| Extruded Punch | 11 | HSS | 60 | Plastic Injection Molding |

| Notching Punch | 14 | HSS | 61 | Edge Notching |

| Chisel Punch | 18 | HSS | 64 | Metal Shearing |

| Form Punch | 19 | HSS | 62 | Forming Operations |

When it comes to precision metalworking, High-Speed Steel (HSS) punches have become invaluable tools due to their exceptional performance and durability. A recent comparative analysis highlighted that HSS punches significantly outperform standard steel alternatives in various parameters. For instance, HSS punches maintain hardness at elevated temperatures, which allows them to endure the rigors of high-speed production without succumbing to deformation. According to industry reports, the longevity of HSS punches can be up to 35% greater than that of conventional punches, which is a critical factor for reducing cost per part in high-volume manufacturing settings.

Furthermore, the wear resistance of HSS punches is another area where they excel. Data from manufacturing studies indicate that using HSS can lead to a reduction in punch replacement frequency by as much as 20%. This is particularly advantageous in industries such as automotive and aerospace, where precision and reliability are paramount. The analysis also suggested that HSS punches have a superior edge retention capability, which enables them to deliver cleaner cuts and more precise shapes, thus minimizing post-processing work and enhancing overall productivity. These performance metrics make HSS punches a go-to choice for metalworking professionals aiming for efficiency and excellence in their projects.

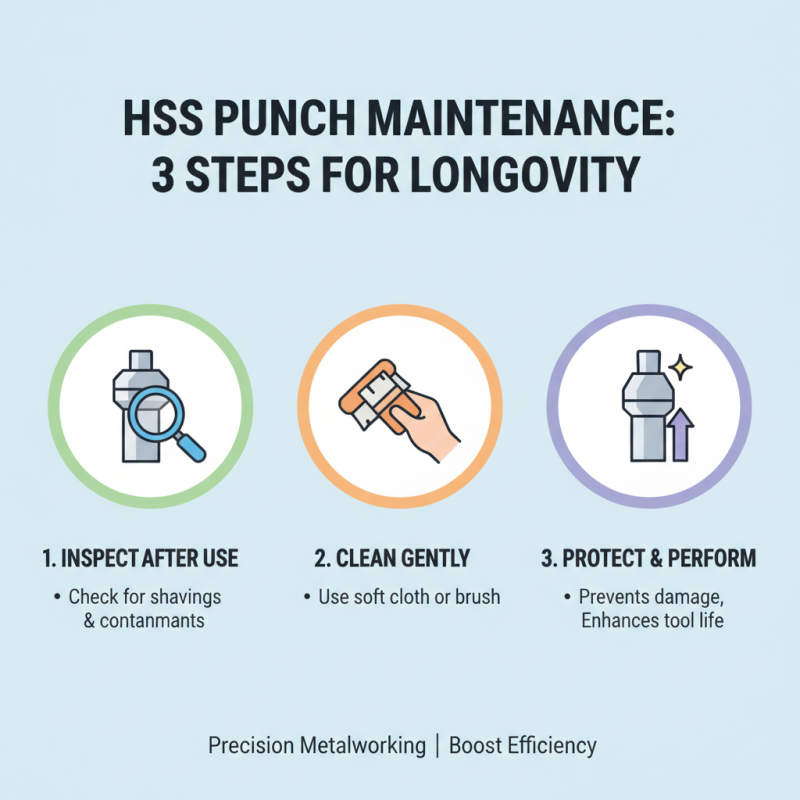

To ensure the longevity of high-speed steel (HSS) punches used in precision metalworking, regular maintenance is essential. One critical aspect of upkeep involves keeping the punches clean and free of debris. After each use, operators should carefully inspect the punches for any buildup of metal shavings or contaminants. Using a soft cloth or brush can help remove these particles, preventing damage to the punch's surface and enhancing its performance in future applications.

Another vital maintenance practice is to regularly check the sharpness of the punch. Dull punches can lead to increased wear and tear on both the tool and the workpiece, compromising quality and precision. A straightforward method to maintain sharpness includes using a fine honing stone or a dedicated sharpening tool, carefully following the original contour of the punch. Additionally, storing punches in a dry, organized environment protects them from rust and physical damage, ensuring they remain in optimal condition for longer periods. By adhering to these practices, metalworkers can effectively extend the lifespan of their HSS punches and maintain high standards of workmanship.

HSS punches, known for their durability and precision, are an essential tool in various industries, including automotive, aerospace, and electronics. According to a report by Smithers Pira, the demand for precision metalworking tools is projected to grow at a CAGR of 4.5% through 2025, reflecting the increasing necessity for high-quality metal components in manufacturing processes. The versatility of HSS punches allows them to effectively handle various materials such as steel, aluminum, and composite materials, making them suitable for applications ranging from metal stamping to die cutting.

In the automotive sector, HSS punches play a pivotal role in the fabrication of parts. The International Organization of Motor Vehicle Manufacturers (OICA) reported that global vehicle production reached over 95 million units in 2021, necessitating reliable and efficient manufacturing tools. Furthermore, HSS punches are critical in the electronics industry for producing precise circuit boards, where the quality of each drilled hole significantly impacts the performance of electronic devices.

The growing trend towards miniaturization in electronics demands tools that can maintain high tolerances, which HSS punches are uniquely equipped to deliver. With their ability to improve productivity and reduce waste, HSS punches are indispensable in meeting the high standards required across these industries.