In the ever-evolving realm of manufacturing, the significance of innovative Machining Cutting techniques cannot be overstated. As production demands increase and industries strive for enhanced efficiency, understanding the latest advancements in this field becomes crucial. According to Dr. John Thompson, an expert in materials engineering, "Mastering the latest Machining Cutting techniques is essential for firms aiming to stay competitive in today's fast-paced market." His insights underline the urgent need for businesses to adapt and incorporate state-of-the-art methodologies to optimize workflow.

The landscape of Machining Cutting is shifting rapidly, driven by emerging technologies and advanced materials. From precision milling to high-speed turning, the techniques available today offer significant opportunities for improvement in productivity and cost-effectiveness. As we look ahead to 2025, it is vital for professionals within the machining sector to familiarize themselves with cutting-edge techniques that not only enhance efficiency but also contribute to sustainability in manufacturing processes. Engaging with these innovations will position companies at the forefront of industry advancements, ensuring they are well-equipped to meet the challenges of the future.

In 2025, the landscape of machining cutting techniques is evolving rapidly, driven by advancements in technology and the quest for improved efficiency. Among the standout techniques is high-speed machining, which minimizes cycle times by using faster feed rates and spindle speeds. This approach not only boosts productivity but also enhances tool life and reduces wear, making it a preferred choice for manufacturers looking to optimize processes. Additionally, the adoption of adaptive machining allows systems to automatically adjust parameters in real-time based on feedback, ensuring consistent quality and precision in cutting operations.

Tips for enhancing efficiency in your machining processes include regularly updating tooling and software to leverage the latest innovations. Implementing centralized monitoring systems can also provide valuable insights into machine performance, enabling data-driven adjustments to workflow. Additionally, training your workforce on emerging techniques and safety protocols will foster an environment of continuous improvement, ensuring your team is well-equipped to handle the demands of modern machining.

As we look toward the future, techniques such as laser-assisted cutting and hybrid machining are gaining traction. These methods combine various technologies to achieve superior results, offering manufacturers the versatility needed to tackle complex materials and geometries. Adopting such innovative approaches will be crucial for staying competitive in the evolving machining landscape.

This chart illustrates the efficiency improvements of various machining cutting techniques projected for 2025. The techniques compared include Laser Cutting, Waterjet Cutting, Plasma Cutting, and CNC Machining.

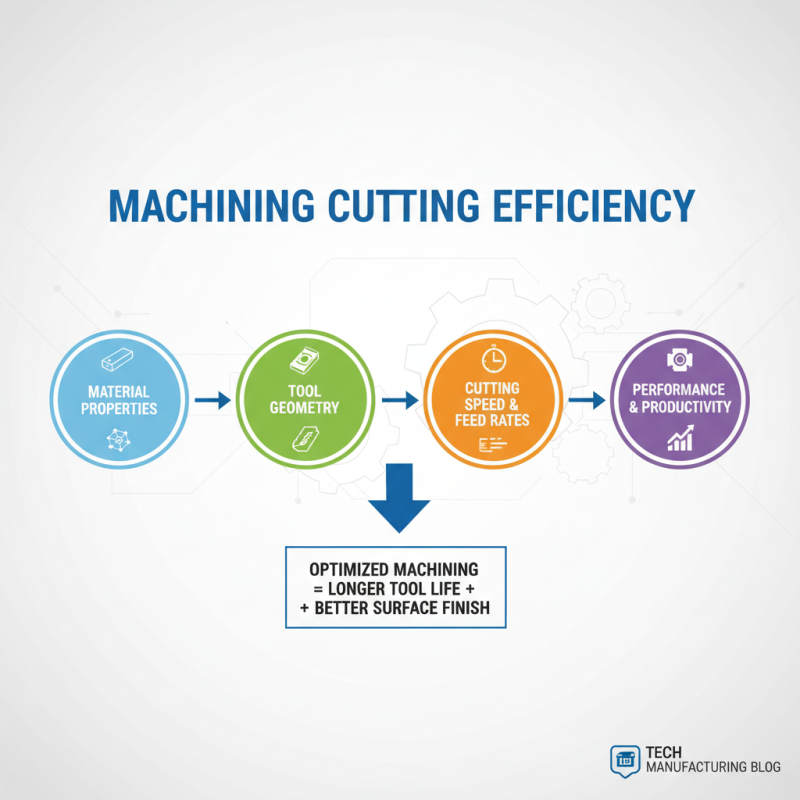

When it comes to machining cutting techniques, understanding the key factors that influence cutting efficiency and performance is paramount. Factors such as material properties, tool geometry, cutting speed, and feed rates play crucial roles in determining the effectiveness of a machining operation. For instance, selecting the right tool material and geometry can lead to significant improvements in tool life and surface finish, thus enhancing overall productivity.

**Tips:** Always consider the compatibility of the tool material with the workpiece material to minimize wear and optimize cutting conditions. Additionally, adjusting the cutting speed according to the material and operation type can prevent overheating and prolong tool life.

Moreover, effective coolant application is another vital aspect affecting cutting performance. Coolants not only reduce friction but also help in dissipating heat generated during the machining process. Choosing the right type of coolant and applying it correctly can vastly improve cutting efficiency and protect the integrity of the workpiece.

**Tips:** Implementing a comprehensive coolant management system can lead to consistent performance and reduced operational costs. Regular monitoring of coolant levels and quality ensures optimal performance and extends tool longevity.

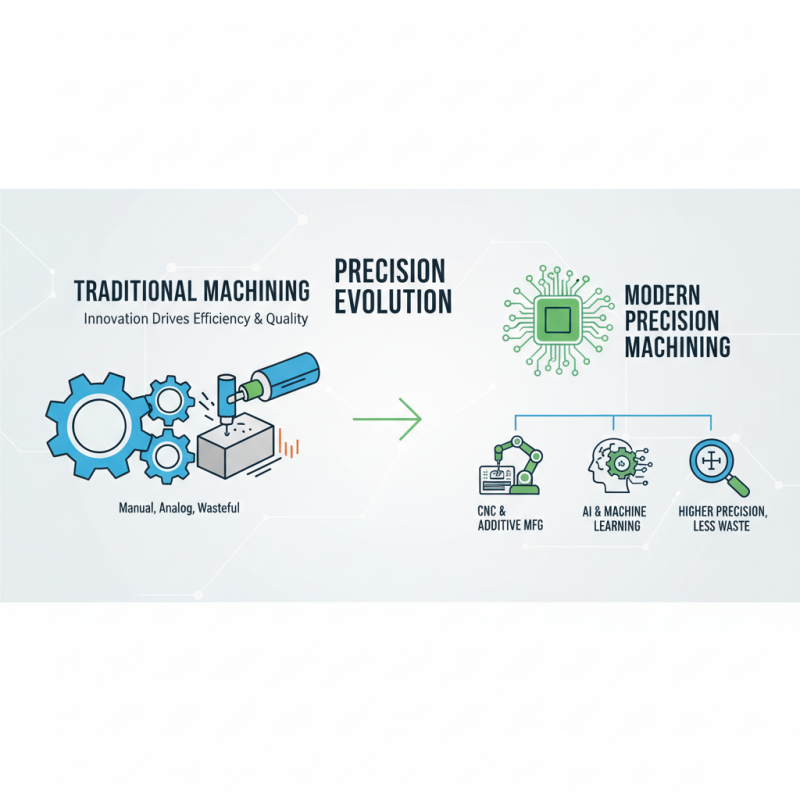

In the rapidly evolving world of precision machining, innovative tools and technologies are playing a pivotal role in improving efficiency and output quality. Recent advancements such as computer numerical control (CNC) systems and additive manufacturing techniques have transformed traditional machining approaches. These technologies enable manufacturers to achieve higher precision, reduce waste, and optimize the use of materials. Furthermore, the integration of artificial intelligence and machine learning algorithms into machining processes allows for real-time data analysis, facilitating adaptive machining that can adjust to various conditions and materials seamlessly.

Additionally, the emergence of smart machining tools equipped with IoT connectivity is enhancing operational insights. These tools can monitor performance metrics and predict maintenance needs, significantly minimizing downtime and increasing overall productivity. The use of advanced materials for cutting tools, such as ceramic and carbide composites, ensures longer tool life and improved cutting performance, further contributing to operational efficiency. As manufacturers continue to adopt these innovative technologies, the landscape of precision machining is set to become even more dynamic and efficient, paving the way for enhanced capabilities and competitiveness in the industry.

As the machining industry continues to evolve, future trends are increasingly focusing on automation and smart technologies. Advancements in Artificial Intelligence (AI) and machine learning are set to revolutionize traditional machining processes by enhancing precision and reducing manual oversight. The integration of these technologies not only allows for real-time monitoring of cutting processes but also enables predictive maintenance, minimizing downtime and optimizing operational efficiency. Manufacturers are expected to leverage data analytics to refine machining techniques, resulting in consistently improved product quality.

Another emerging trend is the shift toward sustainability within the machining sector. The emphasis on reducing waste and maximizing material utilization is driving innovations such as eco-friendly cutting fluids and energy-efficient machinery. As regulatory pressures and societal expectations grow, companies will need to adopt practices that minimize environmental impact. This includes implementing closed-loop systems for recycling materials and embracing alternative energy sources to power machining operations. Future developments in machining will likely center around these sustainable practices, ensuring that efficiency improvements do not come at the expense of ecological responsibility.

Optimizing machining operations is essential for enhancing productivity and maintaining quality in manufacturing. One of the best practices involves employing advanced cutting techniques tailored to specific materials and applications. Understanding the properties of the materials being machined can significantly influence the choice of cutting tools and their geometries. For example, using high-speed steel tools for softer metals can lead to better performance, while carbide tools may be necessary for harder alloys. Additionally, selecting the appropriate feed rate and cutting speed can maximize tool life and improve surface finish.

Another key strategy is the regular maintenance of machining equipment. Keeping machines in optimal condition not only prevents downtime but also ensures consistent quality in production. Implementing a routine inspection schedule can identify potential issues before they escalate, reducing the risk of costly repairs. Furthermore, training operators on the latest machining techniques and practices can significantly enhance operational efficiency. Empowering the workforce with the knowledge of cutting strategies and machine functionalities enhances their ability to troubleshoot and make informed decisions during the machining process. Overall, effective optimization requires a combination of appropriate tool selection, equipment maintenance, and workforce training to achieve superior results in machining operations.