In the realm of manufacturing, the significance of the Tool And Die Design process cannot be overstated. As industries strive for efficiency and precision, experts like John Smith, a renowned authority in Tool And Die Design, emphasize its critical role. He once stated, "The right design in tool and die can make the difference between success and failure in production."

The Tool And Die Design process involves meticulous planning and creativity, where engineers craft precision tools and dies that shape materials into desired products. This process not only enhances operational efficiency but also reduces waste, thereby contributing to more sustainable manufacturing practices. With the growth of advanced manufacturing technologies, the demand for innovative Tool And Die Design continues to rise, making it a cornerstone of modern production.

Moreover, as manufacturing becomes increasingly complex, the importance of effective Tool And Die Design is magnified. It serves as the foundation for producing high-quality parts consistently and meets stringent market demands. As articulated by industry experts, investing in this design process ensures that manufacturers remain competitive in an ever-evolving landscape. The integration of advanced techniques in Tool And Die Design ultimately leads to enhanced profitability and long-term success for businesses.

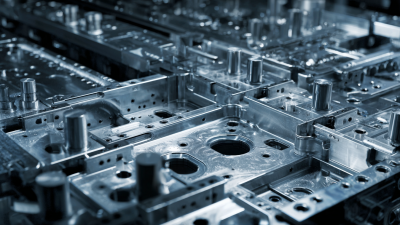

Tool and die design is a critical component in the manufacturing sector, playing a pivotal role in the production of parts and components used across various industries. At its core, tool and die design involves the creation of tools, dies, and molds that shape materials like metal, plastic, and composites into finished products. This process not only focuses on functionality but also emphasizes efficiency, precision, and cost-effectiveness. According to a report from the American Mold Builders Association, the U.S. mold manufacturing industry alone was valued at approximately $2.8 billion in recent years, underscoring the significance of tool and die design in meeting production demands.

The design process typically encompasses several stages, including conceptualization, modeling, prototyping, and testing. During the conceptual phase, engineers collaborate closely with manufacturers to understand their specifications and quality requirements. Utilizing advanced software for Computer-Aided Design (CAD) and simulations, designers can predict how the tools will perform, allowing for adjustments that enhance durability and performance. A study by SMEs highlights that an optimized tool and die design can reduce production time by up to 30%, leading to significant cost savings and improved competitiveness in the market. This process is integral in ensuring that the final products not only meet industry standards but also cater to evolving consumer needs.

The tool and die design process is a critical aspect of manufacturing that influences the efficiency and quality of production.

This process can be broken down into several key stages, each playing a vital role in ensuring that the final tooling meets the required specifications and operational standards. Beginning with the concept development phase, designers collaborate with engineers to understand the product requirements and the different materials involved. According to a report by the National Tooling and Machining Association (NTMA), over 80% of manufacturers cite effective communication in this initial stage as crucial for reducing lead times and costs.

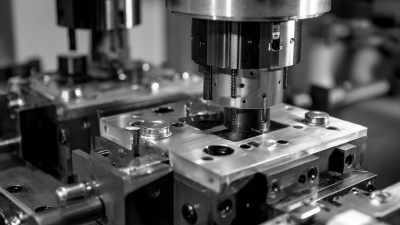

Following concept development, the design and engineering stage involves creating detailed technical drawings and specifications using advanced CAD software. This phase is essential as it allows designers to simulate the functionality of the tool and die, thereby identifying potential issues before actual production begins. High-quality tool and die designs can lead to improved production efficiency and reduced scrap rates, with studies indicating that properly designed tooling can cut production time by as much as 30%. Once the designs are finalized, the prototype stage takes place, where the first tools and dies are produced for testing, ensuring they meet the necessary performance and quality standards.

Finally, the manufacturing stage requires meticulous attention to detail as the tools and dies are produced. This stage often involves multiple processes, including machining, grinding, and assembly, making the precision of these steps paramount. Reports suggest that effective tool and die manufacturing can significantly impact overall manufacturing productivity, as quality tools contribute to fewer machine downtimes and greater output. By understanding and optimizing each key stage of the tool and die design process, manufacturers can enhance their production capabilities and maintain a competitive edge in the market.

The materials employed in tool and die manufacturing play a crucial role in determining the performance and longevity of the tools. Typically, high-strength steel alloys are the go-to choice due to their exceptional hardness and wear resistance. Tool steels, such as D2, A2, and S7, are among the most common selections as they offer the necessary durability to withstand the rigors of production processes. In addition to steel, materials like aluminum and various composites are used for certain applications, especially when a lightweight yet robust solution is required. The selection of material often depends on the specific requirements of the manufacturing process, including the type of components being produced and the tolerances that need to be met.

Technological advancements have significantly enhanced the tool and die manufacturing process. Computer Numerical Control (CNC) machining is now a standard practice, enabling precise fabrication and minimizing human errors. Furthermore, the adoption of 3D printing technology has revolutionized the industry, allowing for rapid prototyping and the creation of complex geometries that were previously difficult to achieve. Additionally, the integration of software tools for design simulation helps engineers to visualize and optimize the performance of their tools before production begins. Together, these materials and technologies contribute not only to the efficiency of the manufacturing process but also to the overall quality of the final products.

The role of tool and die design is pivotal in enhancing production efficiency within the manufacturing sector. Tooling refers to the various tools, dies, and machinery required for the manufacturing process, while die design specifically focuses on creating the molds and shapes that form parts and components. A well-executed tool and die design leads to streamlined production processes, minimizing the time and resources spent on each unit manufactured. By optimizing the design of tools and dies, manufacturers can achieve higher precision and consistency in their products, which is essential for meeting quality standards and customer expectations.

Moreover, effective tool and die design contributes significantly to reducing waste and lowering production costs. When tools are designed to be durable and efficient, they require less frequent replacement and maintenance, ensuring uninterrupted production runs. Additionally, adaptable tool designs can accommodate multiple applications, allowing manufacturers to pivot swiftly in response to market demands. Overall, the strategic design of tools and dies not only enhances production efficiency but also positions companies to remain competitive in a rapidly evolving manufacturing landscape.

| Dimension | Description | Importance |

|---|---|---|

| Design Accuracy | Precision in designing tools and dies to meet specifications. | Leads to reduced material waste and higher quality products. |

| Material Selection | Choosing the right materials for durability and performance. | Ensures longevity of tools and optimum production efficiency. |

| Manufacturing Techniques | Methods used in making the tools and dies, including machining and molding. | Enhances production speed and reduces lead times. |

| Prototyping | Creating a sample tool or die to test design viability. | Identifies potential issues before full production, saving time and costs. |

| Testing and Validation | Evaluating the effectiveness and accuracy of the tools and dies. | Ensures that products meet required standards, improving customer satisfaction. |

The tool and die design process is critical in the manufacturing industry, emphasizing the importance of adhering to industry standards and best practices. Properly designed tools and dies ensure that production runs efficiently, minimizing waste and reducing downtime. Utilizing standardized measurements and materials helps ensure compatibility across components, which is essential for operational effectiveness. The use of advanced software and technology further enhances precision in design, allowing for the creation of intricate components that meet rigorous specifications.

Best practices in tool and die design include thorough planning and prototyping. This stage involves extensive collaboration between designers, engineers, and manufacturers to ensure that the tools will operate as intended. Rigorous testing protocols are also essential, verifying that the tools can withstand the demands of production while delivering consistent quality. Additionally, ongoing training and knowledge sharing within organizations encourage the continual improvement of design processes, driving innovation and efficiency in manufacturing. Following these industry standards not only contributes to better product quality but also fosters a culture of excellence and reliability in manufacturing operations.