A Stamping Die Set is an essential tool in manufacturing. It shapes materials like metal and plastic into specified forms. Experts in the industry emphasize its importance. John Thompson, a leading figure in stamping technology, once said, “A quality stamping die set defines the success of your production line.”

This statement highlights its critical role. Stamping die sets consist of male and female dies. They work together to cut, shape, or form materials accurately. A well-designed set can significantly improve efficiency. However, creating a perfect die set often requires trial and error. It demands precision, yet imperfections can lead to costly mistakes.

Many companies invest heavily in developing these tools. They hope for the best results, but not all succeed. Sometimes, flaws in the design only become apparent during production. In these cases, manufacturers must reassess their approaches. The balance between efficiency and quality in using a stamping die set can be challenging. Ultimately, continuous improvement is key to mastering this technology.

A stamping die set is a crucial tool in manufacturing. It consists of several components that work together to shape materials. The main parts include the die, the punch, and the guide. The die is the mold where the material is shaped. The punch applies force to the material, pressing it into the die. Guides keep everything aligned and stable during the stamping process.

These components can vary in design. Some dies are simple, while others are complex. A well-designed die set can lead to precise outcomes. Precision is key in many industries. However, imperfections can arise. Sometimes, the material may not fill the die correctly. This can lead to defects. Understanding and troubleshooting these issues is important for improvement.

Creating a stamping die set requires both skill and experience. The design phase often involves trial and error. Manufacturers must consider factors like material type and thickness. Each choice impacts the final product. It’s a learning process. Mistakes can be costly, but they also provide valuable lessons. Refining designs based on previous experiences helps in achieving better results in future projects.

This chart illustrates the average time spent on different phases of using a stamping die set in manufacturing. The data represents the typical hours allocated for each process involved in creating stamped products.

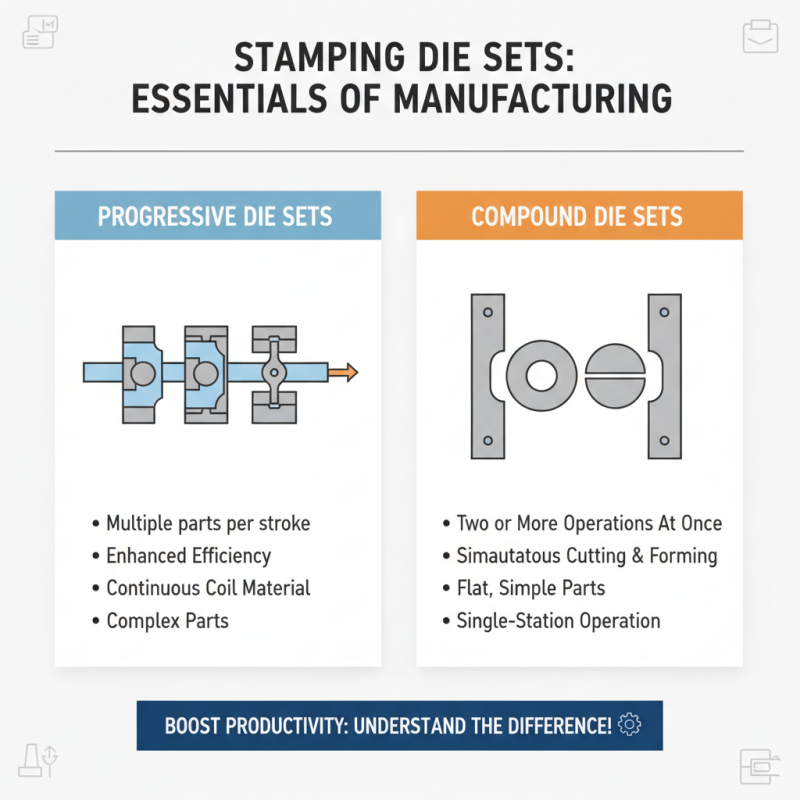

Stamping die sets are essential in manufacturing. There are various types, including progressive and compound dies. Each type serves unique functions in shaping materials. Progressive die sets create multiple parts in one stroke, enhancing efficiency. Compound dies perform two or more operations at once. Understanding their differences can boost productivity.

In a report by the Precision Metalforming Association, 70% of manufacturers report that optimizing die sets improved their production rates. Choosing the right die set can reduce material waste significantly. Ensure you analyze your production needs carefully.

Tips: When selecting a stamping die set, consider the material type. Some materials respond better to certain die types. Also, regular maintenance is crucial. A well-maintained die set lasts longer and performs better. Remember, not every application calls for the most advanced die set. Simplification is sometimes the key.

Stamping die sets are essential tools in manufacturing. They create precise shapes in materials. These sets consist of two main parts: the die and the punch. The die holds the material, while the punch applies force. This force shapes the material into the desired form.

The stamping process begins with positioning the material. It is often metal, such as aluminum or steel. A report from the Precision Metalforming Association indicates that about 36% of metal forming companies use stamping processes. Once the material is in place, the punch moves down rapidly. This exerts high pressure, which can exceed 200 tons. The force causes the material to deform.

Remarkably, even small errors in alignment can lead to wasted materials. It is critical to ensure the setup is accurate. Poorly made dies can result in imperfect shapes. Efficiency dips if adjustments are needed mid-process. According to industry analysis, nearly 15% of production time is lost due to such issues. Continuous improvements in die technology are important, but challenges still exist. Therefore, regular maintenance and operator training remain vital for success in stamping.

| Dimension | Description |

|---|---|

| Material | Steel, Carbide, or Composite materials are commonly used. |

| Type of Die | Progressive, Compound, and Single Station dies. |

| Thickness | Typically ranges from 0.5 mm to 50 mm depending on the application. |

| Die Life | Can last from thousands to millions of cycles based on material and usage. |

| Common Applications | Automotive, Electronics, and Aerospace industries. |

| Process Speed | Can produce parts at rates of several hundred to thousands of units per hour. |

The quality and durability of stamping dies are crucial for efficient manufacturing. Typically, stamping dies are made from high-grade steel, carbide, or even composite materials. The choice of material affects performance considerably. For example, tool steels like D2 are renowned for their hardness and wear resistance. Reports suggest that using high-quality materials can enhance die lifespan by up to 40%. This is vital for minimizing downtime and reducing production costs.

Moreover, durability standards often impact the final product’s quality. Many industry experts recommend regular inspections and maintenance schedules. Neglecting these can lead to premature failure. According to a recent study, about 25% of production delays are directly linked to die wear. Consequently, manufacturers must prioritize the selection of durable materials and develop a structured maintenance approach. Attention to these factors can significantly elevate manufacturing efficiency and output quality.

Stamping die sets play a crucial role across various industries, particularly in automotive and electronics sectors. The automotive industry alone utilizes stamping processes for more than 45% of its parts production. This indicates a heavy reliance on precise manufacturing techniques to ensure quality and efficiency. Moreover, more than 70 million vehicles are produced globally each year, showcasing the vast scale of production and the need for effective stamping solutions.

In electronics, stamping die sets are vital for creating intricate components like connectors and circuit boards. Studies show that demand for electronic components has risen by 15% annually, driven by advancements in technology and consumer electronics. Notably, the lightweight nature of stamped parts can enhance the performance of devices, contributing to energy efficiency. However, challenges remain, such as the need for strict quality control to avoid defects, which can affect overall production yield.

The integration of stamping die sets in manufacturing processes reflects the complexity of modern production systems. Companies often struggle with balancing cost and innovation. While stamping offers speed and precision, the initial investment in die set manufacturing can be significant. Regular evaluation of die performance and potential improvements is necessary to avoid expensive downtimes and to maintain competitive advantage. This ongoing reflection is essential, especially in fast-paced industries where efficiency is key.