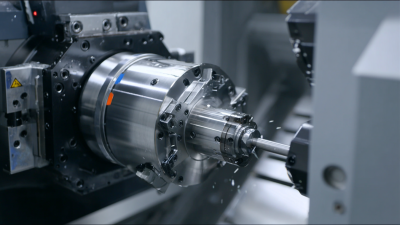

In the world of manufacturing, "Stamping Aluminum Sheet Metal" has emerged as a vital technique that combines efficiency with precision. As the industry continues to evolve, newcomers are often faced with the daunting challenge of mastering this skill. Expert metalworking specialist John Smith, an authority in aluminum processing, once stated, “The key to successful stamping lies not just in technique, but in understanding the unique properties of aluminum itself.” This insight highlights the essential balance between knowledge and practical application in this field.

For beginners venturing into stamping aluminum, grasping the fundamental techniques and tips is crucial. This process involves applying pressure to deform the metal into desired shapes and forms while maintaining the material's integrity. Understanding the characteristics of aluminum, including its malleability and thickness, is paramount for achieving high-quality results. The right approach can help eliminate common pitfalls that many newcomers face, ensuring a smoother learning curve and ultimately leading to more successful outcomes in their metalworking endeavors. As we explore various techniques and practical tips, we aim to provide a comprehensive guide to help you navigate the fascinating realm of stamping aluminum sheet metal with confidence.

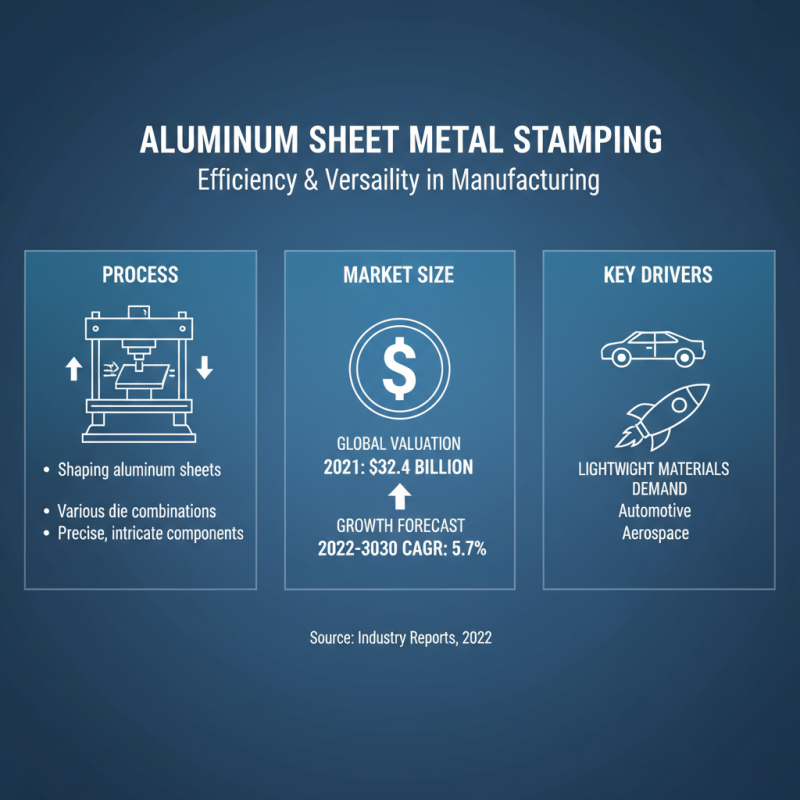

Aluminum sheet metal stamping is a fundamental process in manufacturing that offers both efficiency and versatility. This technique involves the shaping of aluminum sheets through various die combinations, allowing manufacturers to create precise and intricate components. According to industry reports, the global aluminum stamping market size was valued at approximately $32.4 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of around 5.7% from 2022 to 2030. This growth highlights the rising demand for lightweight materials in sectors such as automotive and aerospace, where aluminum's properties make it an ideal choice.

Understanding the basics of aluminum stamping is essential for beginners. The process starts with selecting the right gauge of aluminum sheet, which typically ranges from 0.5 mm to 6.0 mm. The thickness affects the stamping technique and the resultant strength of the part being produced. A well-designed stamping die plays a crucial role in ensuring accuracy and efficiency. Notably, data from the Aluminum Association indicates that aluminum can be stamped more efficiently than many other metals due to its lower weight and excellent malleability, making it suitable for high-volume production runs. By grasping these foundational aspects, newcomers can better appreciate the intricacies and potential of aluminum sheet metal stamping in modern manufacturing.

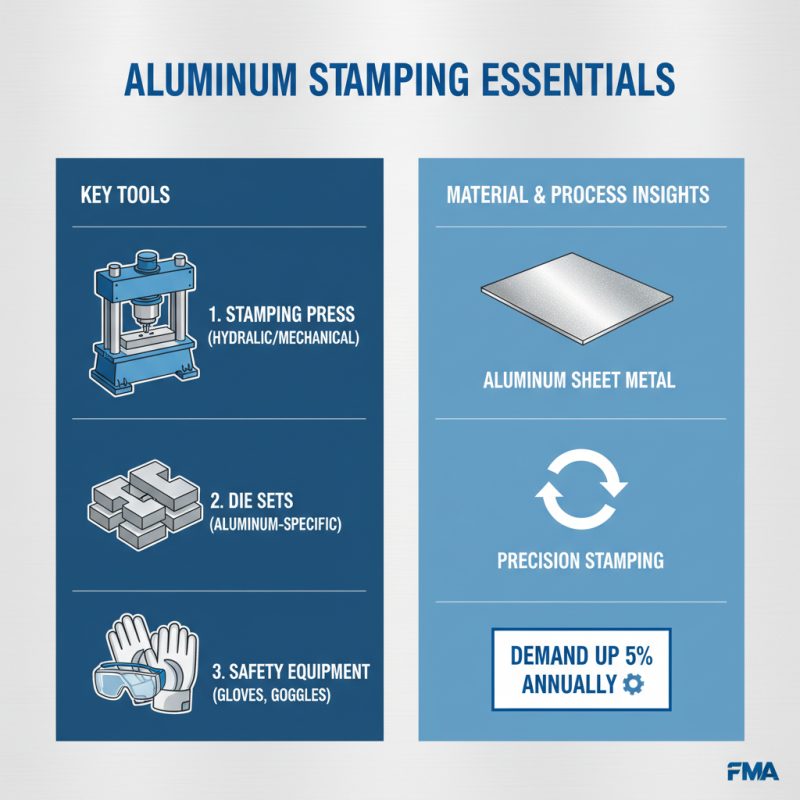

When embarking on a project to stamp aluminum sheet metal, having the right tools and materials is essential for achieving high-quality results. According to the Fabricators and Manufacturers Association International, the demand for precision metal stamping has surged by approximately 5% annually, highlighting the importance of investing in reliable equipment. Key tools include a suitable stamping press, die sets tailored for aluminum, and safety equipment like gloves and goggles. The choice of a hydraulic or mechanical press depends on the complexity and scale of the stamping project; hydraulic presses are often favored for their versatility and ability to handle thicker sheets.

In addition to tools, selecting the appropriate aluminum alloy is crucial for successful stamping. The most commonly used alloys for stamping applications include 3003 and 5052, which offer excellent formability and corrosion resistance. Research indicates that aluminum's lightweight nature can reduce material costs by up to 40% compared to steel, encouraging its use in various industries. Furthermore, proper preparation of the aluminum sheet, including cleaning and appropriate lubrication, can significantly enhance the stamping process by reducing friction and wear on tools. Ensuring that you have the right setup and materials will greatly improve your efficiency and the quality of your stamped products.

Stamping aluminum sheet metal is a fantastic way for beginners to explore metalworking and create unique projects. To start, ensure you have the right tools, such as a stamping die, mallet, and a sturdy workbench. Familiarize yourself with the properties of aluminum, as it is lightweight and easily shaped under pressure.

When stamping, it's crucial to plan your design. Sketch out your idea on paper and transfer it to the aluminum sheet before starting. This will help you visualize the final product and prevent mistakes. Begin with lighter taps from your mallet to make the initial impression, gradually increasing force as necessary. Remember that practice makes perfect; try on scrap pieces before working on your final design.

**Tips:** One helpful tip for beginners is to use a softer mallet to prevent damaging the aluminum and maintain control over each stamp. Additionally, consider using a lubricant on the die to help the material flow and reduce resistance. Lastly, keep your work area organized to avoid frustration and improve your efficiency as you gain confidence in your stamping abilities.

| Technique | Description | Tools Required | Skill Level |

|---|---|---|---|

| Basic Stamping | Using a hammer and stamp to create designs. | Stamp set, hammer | Beginner |

| Die Cutting | Using a die to cut shapes from aluminum sheets. | Die cutter, dies | Intermediate |

| Hydraulic Stamping | Applying hydraulic pressure to stamp designs. | Hydraulic press, stamps | Advanced |

| Embossing | Creating raised designs on the aluminum surface. | Embossing tools, heat source | Intermediate |

| Anodizing for Finish | Electrochemical process to color and protect the metal. | Anodizing tank, solution | Advanced |

When stamping aluminum sheets, beginners often encounter pitfalls that can significantly impact the quality of their work. One common mistake is underestimating the importance of tooling setup. Ensuring that your dies are properly aligned and maintained can prevent issues like uneven edges and misaligned cuts. Take the time to check the pressure settings on your stamping machine as well; insufficient pressure can lead to incomplete stamping, while excessive pressure might warp the metal sheet.

Another frequent error arises from the choice of aluminum thickness. Beginners sometimes select materials that are too thick for their equipment, leading to difficulties in achieving precise stamps. It’s essential to understand the capabilities of your tools and choose aluminum sheets that match those specifications. Additionally, neglecting to perform trial runs can lead to unexpected results when moving to actual projects. Conducting test stamps can help identify potential issues and fine-tune your techniques before committing to the final product.

When working with stamped aluminum, enhancing the appearance of the finished product can significantly impact both its aesthetic appeal and marketability. According to a report by the Aluminum Association, the global aluminum market is projected to grow substantially, driven by its lightweight properties and versatility across various industries. Thus, implementing finishing techniques can make your stamped aluminum sheet metal stand out.

One effective method for finishing is anodizing, which increases corrosion resistance and enhances the surface condition. Anodizing not only allows for a variety of colors but also adds durability, making it ideal for both decorative and functional applications. Another popular finishing technique is powder coating, which provides a hard, protective layer and comes in almost any color imaginable, allowing for customization that can cater to specific design needs. The surface preparation before these processes is crucial; for instance, using a proper cleaning agent ensures that there’s no residue that could compromise the adhesion of finishes.

Tip: Always ensure that the aluminum is thoroughly cleaned and free from oils or contaminants before applying finishes. Using a mild detergent followed by a rinse can achieve this easily.

In addition to these techniques, post-processing such as polishing or bead blasting can create unique textures and appearances. Utilizing these methods not only enhances the visual quality of stamped aluminum but also provides additional protective benefits, reinforcing the material's functionality.

Tip: Experiment with different finishing techniques on smaller samples to determine the best result for your specific application before committing to larger production runs.