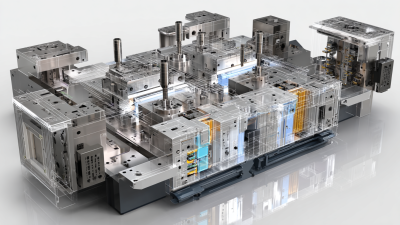

In the competitive landscape of manufacturing, achieving maximum efficiency and quality is paramount, particularly in processes like Mold Stamping. This vital technique involves shaping materials through molds, ensuring precise dimensions and surface finishes. However, optimizing the Mold Stamping process requires a strategic approach that encompasses various elements, including machinery calibration, material selection, and workflow integration.

By focusing on these factors, manufacturers can minimize waste, reduce lead times, and enhance product quality, thereby driving profitability and customer satisfaction. This guide aims to provide actionable insights on refining your Mold Stamping process, enabling you to harness its full potential while maintaining high standards in production. Embracing these optimization strategies will not only elevate your operational performance but also position your business for sustained success in an ever-evolving market.

Mold stamping is a critical manufacturing process that transforms raw materials into high-quality components with precision. Understanding the key principles and processes involved in mold stamping is essential for optimizing efficiency and quality. At its core, mold stamping relies on precise mold design, the selection of appropriate materials, and the integration of advanced technologies. By leveraging innovative techniques such as imaging-based analysis, manufacturers can significantly reduce costs while increasing the accuracy of their operations.

Recent advancements in related fields, such as single-cell RNA research, showcase the benefits of employing technology to enhance analytical capabilities. For instance, a new imaging technique allows researchers to examine millions of cells efficiently, which mirrors the potential improvements in mold stamping processes. The adoption of modern technologies, such as automation and real-time monitoring, can streamline production workflows, minimize waste, and ensure consistent product quality. This blend of traditional principles and modern technology will pave the way for manufacturers to achieve maximum efficiency in their mold stamping operations.

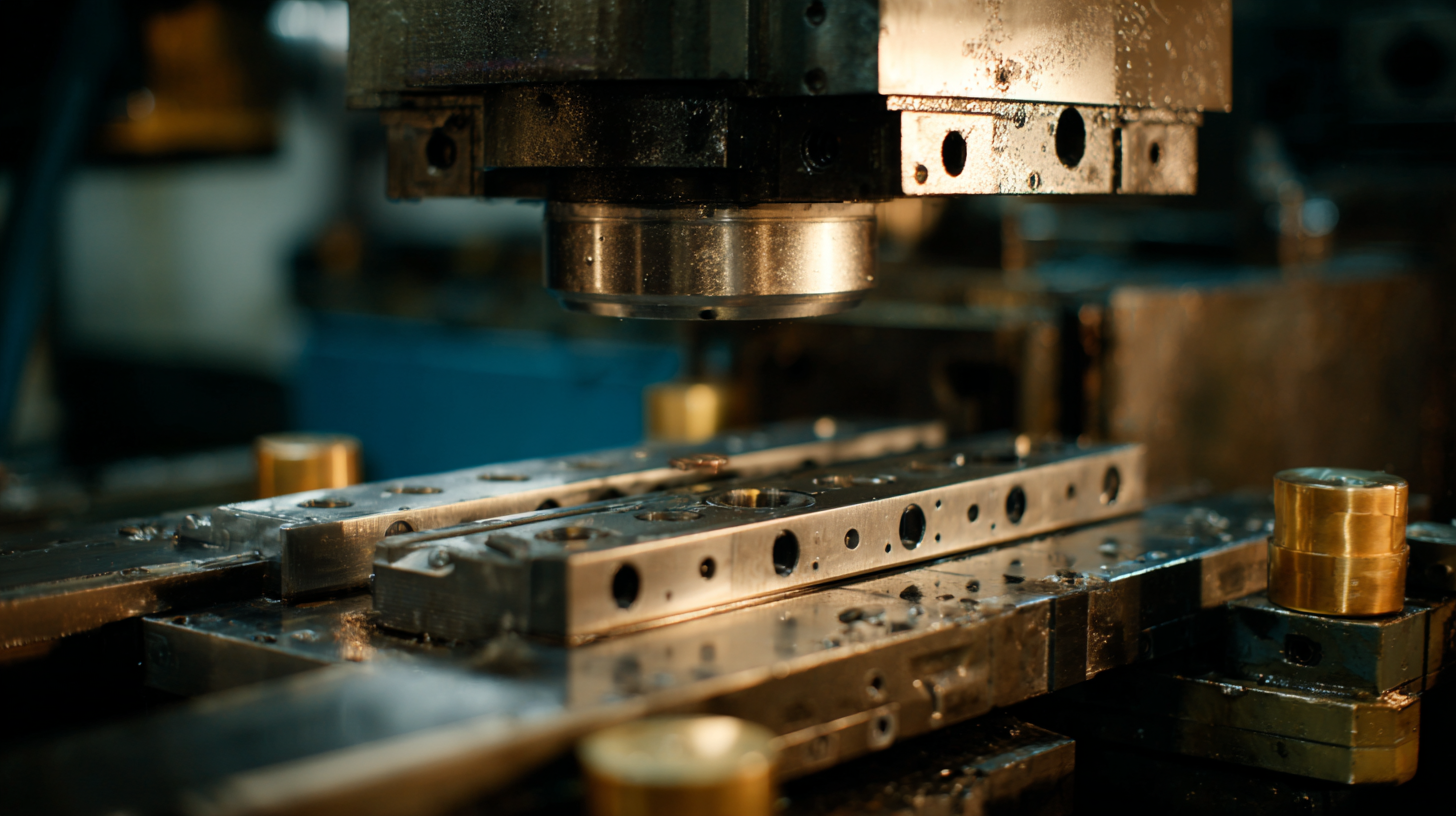

Identifying bottlenecks in the mold stamping workflow is crucial for optimizing efficiency and enhancing product quality. By leveraging advanced technologies, manufacturers can collect and analyze data from various sources, such as machinery performance logs and operator observations. This data-driven approach allows for the identification of inefficiencies within the workflow, providing a clear picture of where delays and quality issues may arise.

Integrating AI and machine learning into the process further enhances this analysis. For instance, predictive maintenance models can forecast equipment failures before they occur, reducing downtime. Additionally, autonomous robotics can be deployed to streamline repetitive tasks, freeing up human resources for more complex duties. By overlaying multiple data sources, manufacturers can implement targeted strategies to mitigate bottlenecks, ultimately leading to a more efficient and high-quality mold stamping process.

The integration of advanced technology in mold stamping processes is revolutionizing efficiency and quality in manufacturing. According to a report by MarketsandMarkets, the global mold and die market is projected to reach $100 billion by 2025, largely driven by automation and smart manufacturing technologies. Implementing automated systems reduces human error and increases speed, ensuring that manufacturers can meet growing demand without sacrificing quality.

Tips for optimizing mold stamping through technology include investing in predictive maintenance systems. These systems can utilize data analytics to foresee equipment failure before it happens, significantly reducing downtime and maintenance costs. Another strategy is to employ computer-aided design (CAD) software that allows for detailed visualization and simulation of the mold designs prior to production, leading to better outcomes and fewer material wastages.

Additionally, embracing Industry 4.0 technologies such as IoT (Internet of Things) devices can provide real-time monitoring of production processes. This connectivity allows for immediate adjustments based on performance data, optimizing operations continuously. Implementing these advanced technologies can not only enhance production efficiency but also ensure the highest quality in mold stamping projects, ultimately leading to increased customer satisfaction and market competitiveness.

The following chart represents the efficiency and quality improvements observed in the mold stamping process through the implementation of advanced technology over a 12-month period.

In the pursuit of optimizing the mold stamping process, selecting the right materials is a crucial factor that influences both quality and efficiency. Recent industry reports indicate that material selection can enhance product durability by up to 20% while reducing production costs by around 15%. The integration of advanced materials that meet sustainability goals not only addresses environmental concerns but also aligns with the growing market demand for greener manufacturing practices.

Tip: When choosing materials, consider those that are recycled or have lower environmental impact to enhance your company's sustainability profile while maintaining high standards of quality.

Moreover, the advancements in automation and digital technologies significantly improve the mold stamping workflow. Companies embracing Industry 4.0 technologies report a 30% increase in production efficiency. This technological shift enables real-time monitoring and adjustments, leading to fewer errors and enhanced output consistency.

Tip: Invest in training staff to effectively use new technologies; well-informed teams can maximize the benefits of automation, leading to both improved processes and product quality.

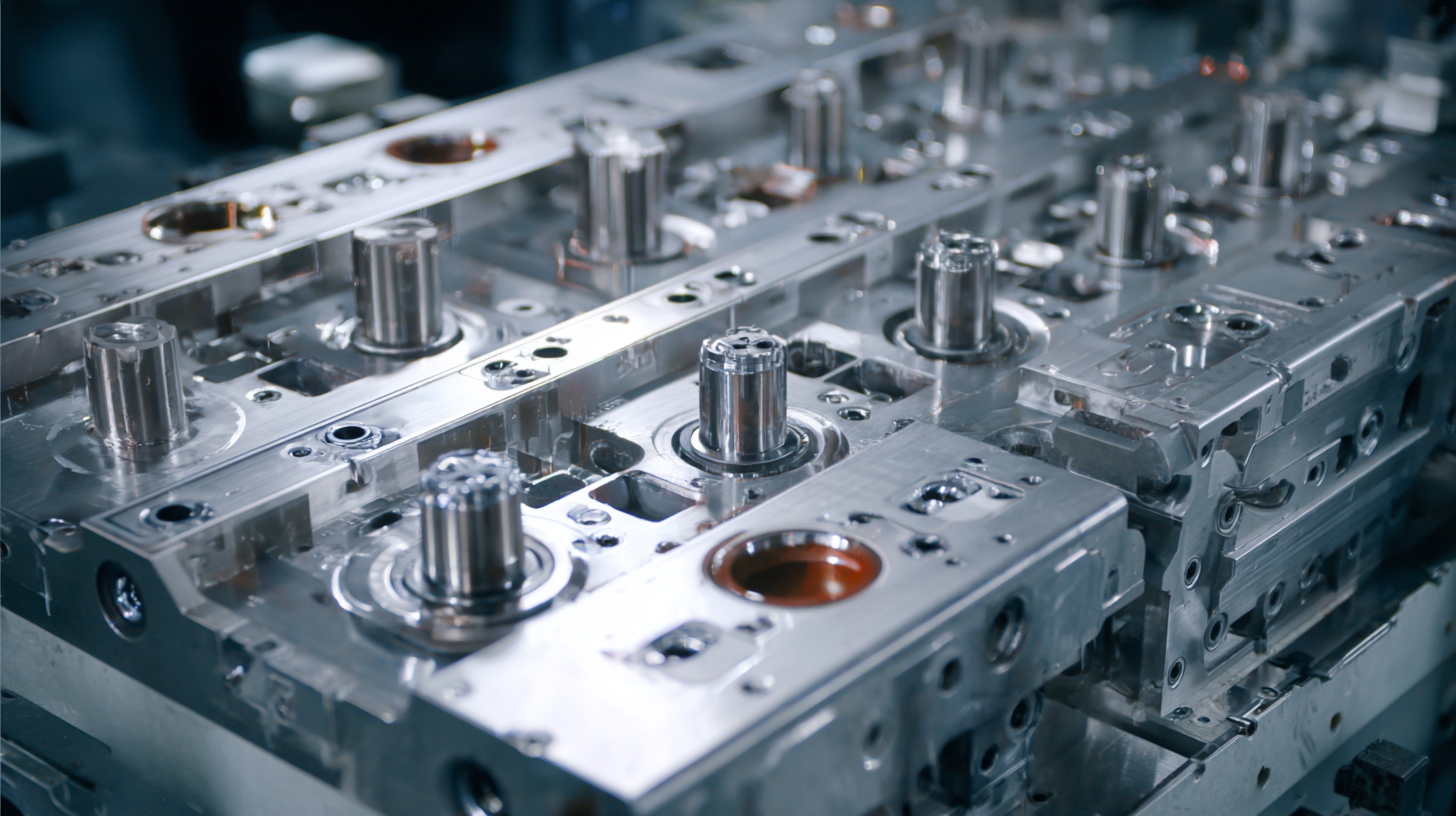

Regular maintenance is crucial in optimizing the mold stamping process, as it directly affects both efficiency and product quality. Establishing a routine maintenance schedule ensures that all machinery and tools are functioning at their best, which can significantly reduce downtime and prevent costly errors. This includes regular inspections, lubrication of moving parts, and timely replacement of worn-out components. By proactively addressing potential issues, manufacturers can maintain a smooth workflow and ensure that their stamping operations remain reliable and efficient.

In addition to maintenance, implementing stringent quality control measures is vital for achieving consistent results in mold stamping. This involves setting clear quality standards and conducting regular inspections throughout the production process. By utilizing techniques such as statistical process control (SPC) and end-of-run inspections, companies can quickly identify deviations from quality benchmarks and take corrective action before defects occur. Furthermore, continuous training for operators on best practices and quality assurance processes fosters a culture of excellence, ultimately leading to better product quality and customer satisfaction.

| Maintenance Activity | Frequency | Duration (Hours) | Impact on Efficiency (%) | Impact on Quality (% Improvement) |

|---|---|---|---|---|

| Visual Inspection | Daily | 0.5 | 10 | 5 |

| Lubrication | Weekly | 1 | 15 | 10 |

| Calibration | Monthly | 4 | 20 | 15 |

| Components Replacement | Quarterly | 3 | 25 | 20 |

| Thorough Clean-Up | Monthly | 2 | 30 | 10 |