In today's highly competitive manufacturing landscape, optimizing your Metal Fabrication process is not just a strategy for improvement; it's a necessity for ensuring increased efficiency and superior quality. As industries evolve and customer demands grow more complex, businesses must adapt their fabrication practices to deliver the best possible results.

This guide aims to provide comprehensive insights into the best practices, innovative technologies, and proven methodologies that can significantly enhance your metalworking operations. From streamlining workflow and minimizing waste to employing cutting-edge tools and techniques, we will explore key strategies that can transform your Metal Fabrication processes.

With a focus on practical solutions and real-world applications, this ultimate guide will empower you to elevate your production capabilities, ultimately leading to greater customer satisfaction and a stronger market position.

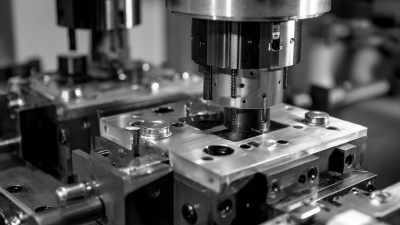

Identifying common inefficiencies in metal fabrication processes is crucial for manufacturers aiming to enhance productivity and product quality. According to a report by the Fabricators & Manufacturers Association (FMA), inefficiencies can account for up to 30% of the total production time in metal fabrication. Factors such as equipment downtime, outdated technology, and poor workflow design contribute significantly to these inefficiencies, leading to increased operational costs and delayed project timelines.

One effective tip to combat inefficiencies is to implement a preventive maintenance program for machinery. Research indicates that regular maintenance can reduce equipment failure rates by up to 40%, subsequently minimizing downtime. Additionally, investing in automation technologies, such as CNC machines, can streamline processes. A study from the National Association of Manufacturers (NAM) found that companies employing automation saw productivity increases of 20-30%.

Another key area to focus on is training and skill development for employees. Ensuring that staff are well-trained in the latest fabrication techniques could lead to fewer errors and higher quality outcomes. According to the Welding Equipment Manufacturers, a well-trained workforce can increase efficiency by 15% while also enhancing overall workplace safety.

In the competitive landscape of metal fabrication, streamlining workflow is essential for enhancing efficiency and reducing waste. One effective strategy is to implement lean manufacturing principles. By identifying and eliminating non-value-added activities in the production process, businesses can significantly improve their operational efficiency. For instance, utilizing value stream mapping can help visualize the entire process, making it easier to pinpoint bottlenecks and areas of waste. Prioritizing the rearrangement of workstations based on the flow of materials can also minimize unnecessary movements, leading to a smoother workflow.

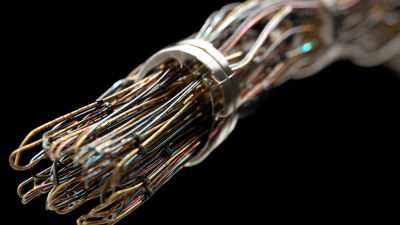

Another key strategy is to invest in technology that automates repetitive tasks. Automation tools, such as CNC machines and robotic welders, not only enhance precision but also free up skilled workers to focus on more complex tasks. This not only reduces the chance of human error but also accelerates production cycles, leading to faster turnaround times. Additionally, regular training programs for employees on new technologies and techniques can foster a culture of continuous improvement, ensuring that everyone is aligned with the goals of efficiency and quality. By adopting these strategies, metal fabrication companies can successfully streamline their operations and reduce waste, positioning themselves for greater success in the industry.

| Dimension | Current Metric | Target Metric | Improvement Strategy |

|---|---|---|---|

| Cycle Time | 45 minutes | 30 minutes | Implement Lean Manufacturing Techniques |

| Material Waste | 20% | 10% | Optimize Material Cutting Plan |

| Overall Equipment Efficiency (OEE) | 75% | 85% | Regular Maintenance and Upgrades |

| Defect Rate | 5% | 2% | Implement Quality Control Checkpoints |

| Employee Training Hours | 10 hours/month | 15 hours/month | Increase Training Sessions on New Equipment |

In the competitive landscape of metal fabrication, enhancing quality control measures is paramount for achieving both efficiency and superior product standards.

According to a recent report by the Fabricators and Manufacturers Association, incorporating advanced quality control techniques can reduce defect rates by up to 30%. This significant reduction not only cuts down on rework costs but also enhances customer satisfaction, paving the way for repeat business and improved reputation in the industry.

To effectively bolster quality control, many fabricators are turning to automation and real-time data monitoring. The integration of technologies like AI and

IoT devices allows for continuous inspection throughout the manufacturing process. A study from the National Institute of Standards and Technology found that companies implementing such technologies experience deeper insights into manufacturing quality metrics, leading to a 25% decrease in waste.

As these innovations become more accessible, adopting them is no longer a luxury but a necessity for fabricators aiming to stay ahead in a quality-conscious market.

In today's fast-paced manufacturing landscape, leveraging technology is essential for optimizing metal fabrication processes. The integration of advanced technologies such as

artificial intelligence (AI) and

machine learning (ML) can significantly enhance efficiency and quality outcomes. By automating routine tasks and improving data analysis, organizations can make informed decisions that lead to streamlined operations and reduced waste.

Tips for Leveraging Technology:

In the metal fabrication industry, workforce performance plays a pivotal role in optimizing processes and enhancing overall quality. According to a report by the Fabricators & Manufacturers Association (FMA), companies that invest in training and skill development for their employees can see productivity increases of up to 20%. This significant gain occurs because well-trained workers are more adept at using advanced machinery and software, resulting in fewer errors and higher precision in production.

Moreover, embracing continuous education can lead to greater job satisfaction and retention rates among skilled workers. A study by the National Association of Manufacturers (NAM) found that organizations that prioritize employee development experience a 30% lower turnover rate. By implementing structured training programs focused on advanced machining techniques, safety protocols, and quality control measures, businesses can cultivate a highly skilled workforce capable of driving innovation and operational efficiency within the metal fabrication sector. By investing in your team, you not only enhance productivity but also contribute to the long-term success of your organization.