In today's highly competitive manufacturing landscape, optimizing processes is essential for achieving efficiency and profitability. A report by the International Federation of Robotics indicates that the adoption of advanced manufacturing technologies, including EDM (Electrical Discharge Machining), has seen a significant increase, projected to grow by 12% annually over the next five years. Among these technologies, Small Wire EDM has emerged as a game-changer, providing manufacturers with the ability to create intricate designs with unmatched precision. This technique is particularly beneficial for industries such as aerospace and medical devices, where tight tolerances and complex geometries are paramount. By leveraging Small Wire EDM, companies can not only enhance their production capabilities but also reduce lead times and material waste, leading to a more sustainable and cost-effective manufacturing process.

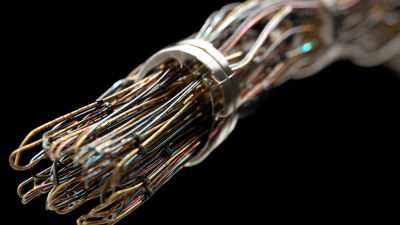

Small Wire EDM (Electrical Discharge Machining) has emerged as a pivotal technology in modern manufacturing processes. This technique utilizes a thin, electrically charged wire to cut through metal with precision, allowing manufacturers to create intricate shapes and designs that would be difficult or impossible to achieve with traditional machining methods. Understanding the basics of small wire EDM is crucial for optimizing production, as it not only enhances the accuracy of parts but also reduces material wastage.

The process begins with the setup of a wire electrode, usually measuring 0.1 to 0.3 mm in diameter, which is guided by a computer-controlled CNC system. As the wire moves through the workpiece, sparks are generated at a high frequency between the wire and the metal, effectively melting and vaporizing the unwanted material. This non-contact process minimizes the impact on the workpiece, preserving its integrity and enabling the creation of complex geometries.

Incorporating small wire EDM techniques into manufacturing can significantly improve cycle times and elevate the quality of the finished product. Its ability to handle hardened materials and tight tolerances makes it an excellent choice for the aerospace, automotive, and medical industries, where precision is paramount. As manufacturers continue to seek innovative ways to enhance efficiency and performance, small wire EDM stands out as a formidable solution that meets the demands of today's advancements.

| Parameter | Description | Impact on Manufacturing |

|---|---|---|

| Wire Diameter | The thickness of the wire used in the EDM process. | Affects machining precision and the complexity of cuts. |

| Cutting Speed | Rate at which the wire cuts through material. | Impacts cycle time and productivity of the manufacturing process. |

| Power Settings | Electrical power supplied to the wire during cutting. | Higher power can reduce cutting time but may affect surface finish. |

| Wire Material | The composition of the wire used (e.g., brass, coated). | Can influence cutting efficiency and wear on machining equipment. |

| Flush Pressure | Pressure of coolant or flushing liquid during the process. | Affects chip removal and surface finish quality. |

| Setup Time | Time taken to prepare the machine for production. | Directly impacts overall production efficiency. |

Incorporating small wire EDM (Electrical Discharge Machining) techniques into manufacturing processes can yield significant advantages, particularly in precision and cost-effectiveness. According to industry reports, small wire EDM allows manufacturers to achieve tolerances as tight as 5 microns, which is essential for applications requiring high accuracy, such as aerospace and medical device production. The process also minimizes material waste, with wastage rates often reduced by up to 20%, ultimately leading to lower operational costs and increased efficiency.

Furthermore, small wire EDM techniques empower manufacturers to streamline production workflows. A survey by a leading machining industry publication highlighted that companies implementing these techniques reported a 15% increase in production speed and a 25% improvement in overall productivity. This increase is largely attributed to the technology's capability to handle intricate geometries and complex shapes that traditional machining methods struggle with. As industries continue to seek innovative ways to enhance performance while controlling costs, embracing small wire EDM is proving to be an effective strategy for maintaining a competitive edge.

Small Wire EDM (Electrical Discharge Machining) is rapidly transforming the manufacturing landscape by enhancing precision and efficiency in various industries. According to a report by **Research and Markets**, the global EDM market is projected to reach USD 7.08 billion by 2027, growing at a CAGR of 6.5%. This highlights the increasing adoption of innovative machining techniques, such as Small Wire EDM, in manufacturing workflows.

Implementing Small Wire EDM processes begins with understanding the equipment capabilities and selecting suitable wire types. Brass wires are commonly used for their excellent machining properties, while coated wires can improve the surface finish. A key step is to optimize the machine settings—such as pulse duration, feed rate, and flushing conditions—based on material characteristics. Studies indicate that optimizing these parameters can enhance machining speed by up to 30%, significantly reducing production timelines. Furthermore, regular maintenance and operator training play critical roles in maximizing the efficiency and longevity of EDM machines, ensuring that manufacturers can meet growing demands without sacrificing quality.

In small wire EDM operations, manufacturers often face common challenges that can hinder productivity and precision. One significant issue is wire wear, which can lead to inconsistent cutting quality. To combat this, regularly monitor wire tensions and employ a suitable wire type for your specific material. This ensures optimal cutting performance and reduces the frequency of wire changes, saving both time and resources.

Another challenge is maintaining accurate part dimensions, which can be affected by machine settings and environmental conditions. To address this, implement routine maintenance checks and calibrate your machines regularly. Furthermore, consider investing in advanced software that provides real-time adjustments based on feedback from the manufacturing process, allowing for more precise control.

Lastly, operators may struggle with managing debris removal effectively, which can impact the overall machining process. To optimize debris removal, use a high-efficiency filtration system and maintain fluid pressure at optimal levels. Regularly clean the machine to ensure unobstructed cutting paths, enhancing both efficiency and product quality in small wire EDM operations.

When optimizing your manufacturing process with small Wire EDM (Electrical Discharge Machining) techniques, measuring success is crucial. Key performance metrics should focus on factors such as precision, cycle time, and cost efficiency. Precision is vital as the primary aim of utilizing EDM is to achieve intricate designs with exact tolerances. Regularly monitoring the dimensional accuracy of produced parts can provide insights into the effectiveness of your current processes and equipment setup.

Cycle time is another critical metric for evaluation. It captures the amount of time required to complete a machining job, and reducing this can significantly enhance productivity. By analyzing cycle times across various jobs, manufacturers can identify bottlenecks and areas that require improvement. Implementing lean practices alongside EDM techniques can lead to substantial reductions in cycle time, ultimately translating into increased output and profitability.

Cost efficiency emerges as a fundamental metric in the competitive landscape of manufacturing. Keeping track of material waste, energy consumption, and operational costs associated with Wire EDM processes will provide a comprehensive view of overall efficiency. By leveraging advanced monitoring systems, manufacturers can gain real-time insights into their operations, allowing for timely adjustments that can reduce costs while maintaining high-quality standards.