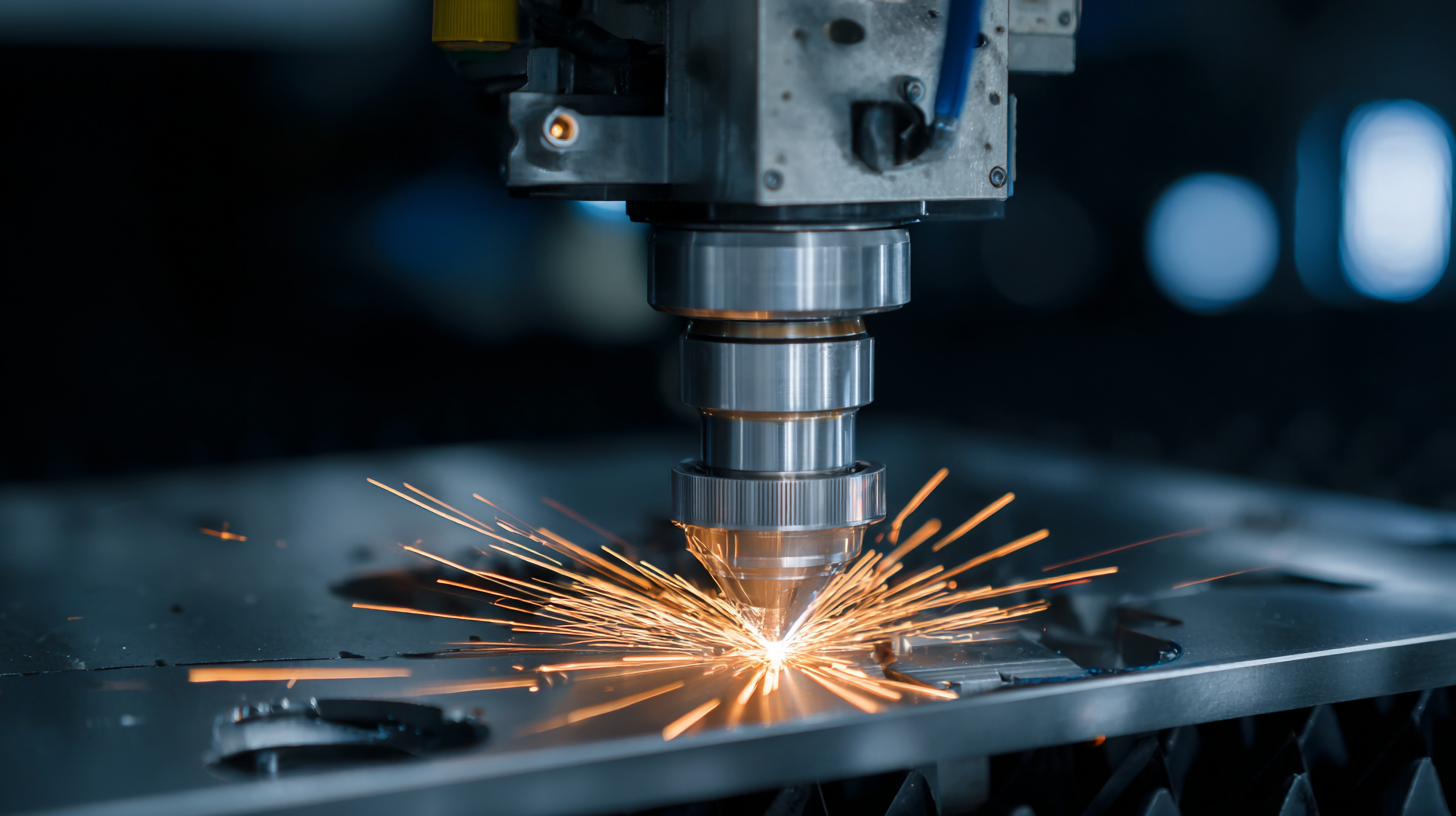

In the world of precision machining, optimizing EDM machine parts is crucial for enhancing both accuracy and efficiency. Electrical Discharge Machining (EDM) relies on the intricate interplay between various components to produce intricate shapes and fine details in conductive materials. As industries demand higher precision and quicker turnaround times, the focus on the optimization of EDM machine parts has never been more critical. This blog will delve into the fundamental aspects of improving EDM machine parts to achieve better performance, reduced operational costs, and longer tool life. By applying advanced techniques and innovative practices, manufacturers can unlock the full potential of their EDM systems, driving productivity and quality to new heights. Whether you are a seasoned technician or new to the field, understanding how to optimize these essential components will empower you to elevate your machining processes effectively.

In the world of precision machining, optimizing EDM machine parts is crucial for enhancing both accuracy and efficiency. Electrical Discharge Machining (EDM) relies on the intricate interplay between various components to produce intricate shapes and fine details in conductive materials. As industries demand higher precision and quicker turnaround times, the focus on the optimization of EDM machine parts has never been more critical. This blog will delve into the fundamental aspects of improving EDM machine parts to achieve better performance, reduced operational costs, and longer tool life. By applying advanced techniques and innovative practices, manufacturers can unlock the full potential of their EDM systems, driving productivity and quality to new heights. Whether you are a seasoned technician or new to the field, understanding how to optimize these essential components will empower you to elevate your machining processes effectively.

Understanding the basics of EDM (Electrical Discharge Machining) machine parts is fundamental for achieving precision optimization in your machining processes. EDM machines rely on a series of components, including electrodes, workpieces, and dielectric fluids, which interact to create the desired shapes and finishes. Each part plays a crucial role in maintaining accuracy and enhancing productivity. For instance, selecting the right type of electrode material can significantly influence the machining speed and surface integrity of the finished part. Copper and graphite are popular choices, each offering distinct advantages depending on the specific requirements of the application.

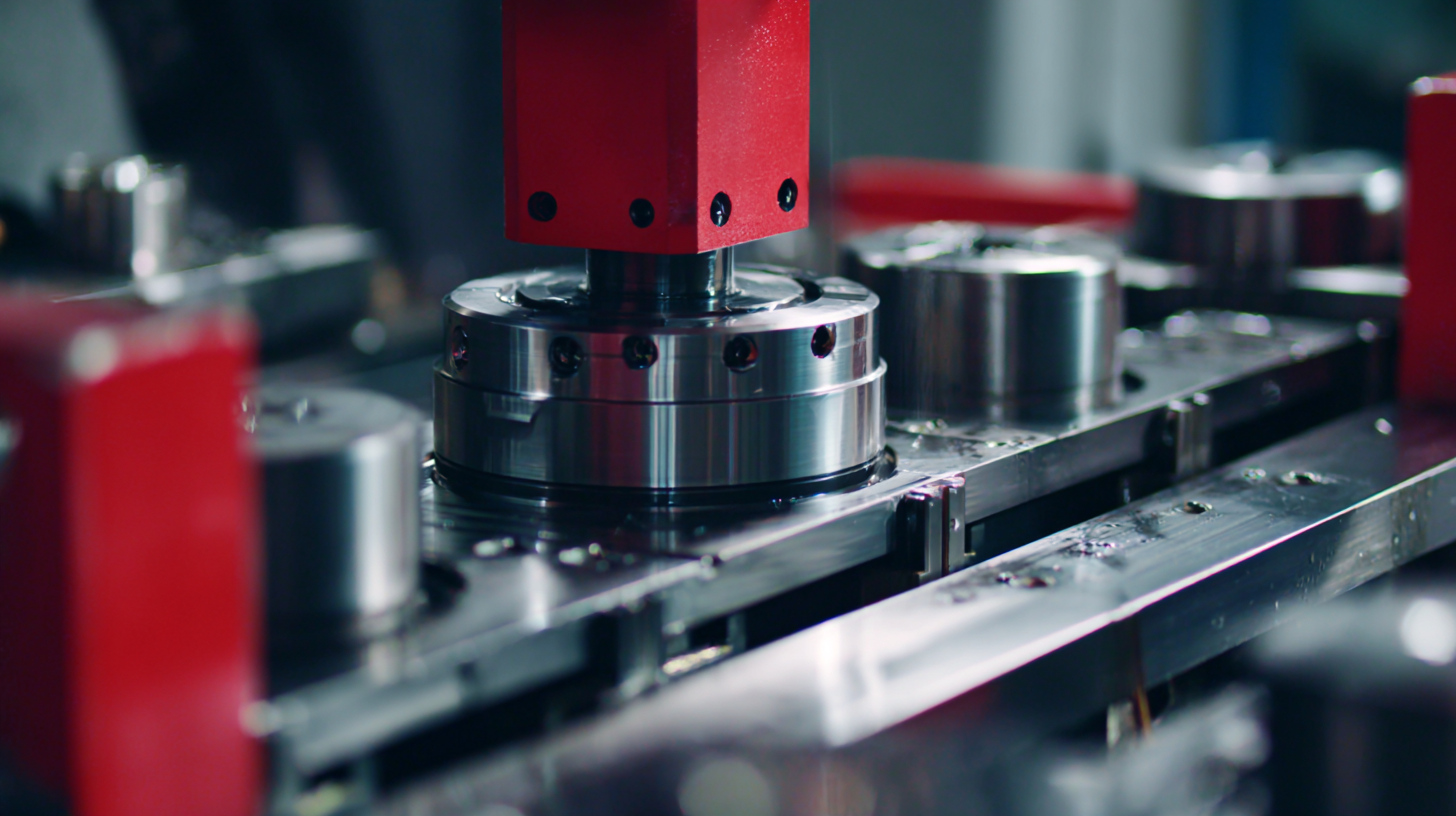

Moreover, regular maintenance and calibration of EDM parts can prevent issues that lead to deviations in precision. Ensuring that the machine’s servo mechanisms and guiding systems are functioning correctly is vital for accurate machining. Additionally, understanding the optimal settings for machining parameters—such as pulse duration, current intensity, and dielectric fluid pressure—can greatly improve both efficiency and part quality. By prioritizing the interplay of these elements and continually assessing performance, you can effectively enhance the precision of your EDM processes.

Optimizing EDM (Electrical Discharge Machining) machine parts is crucial for manufacturers looking to enhance precision and efficiency in their operations. Key factors impacting the efficiency of EDM machines include the quality of components, machine programming, and the integration of automated technologies. Precision in machine parts leads to better functionality, which directly impacts the overall output and reduces manufacturing errors. Advanced materials and coatings for EDM parts can significantly improve lifespan and performance, ensuring that businesses maintain high production standards.

Moreover, the rise of digitalization, IoT, and AI technologies is transforming the EDM landscape. Manufacturers are leveraging these advancements to enhance operational efficiency, as automated processes streamline production and reduce human error. The use of AGVs (Automated Guided Vehicles) is gaining traction; it increases the flow of materials without compromising connectivity, which is essential for maintaining seamless operations. As the EDM sector continues to evolve, focusing on these key factors will enable manufacturers to optimize their processes, ultimately leading to reduced costs and an increase in competitive advantage in diverse industries such as aerospace and medical devices.

To ensure the longevity and precision of your Electrical Discharge Machining (EDM) equipment, regular maintenance of its components is crucial. One of the most effective ways to maintain your wire EDM machine is to monitor its performance closely. Telltale signs, such as decreased speed or frequent wire breakage, indicate that it may be time for a thorough inspection and maintenance. Maintaining optimal performance not only enhances efficiency but also prolongs the lifespan of the machine.

Best practices for regular maintenance include cleaning the machine regularly to prevent buildup that can lead to performance issues. Additionally, checking the coolant levels and ensuring that the filtration system is functioning properly are vital steps in preventing potential problems. Regularly inspecting and changing worn parts can also prevent mechanical failures and ensure the machine operates at peak performance. By staying attentive to these maintenance tasks, operators can enjoy smoother operations and consistent, high-precision results from their EDM systems.

Optimizing EDM machine parts for enhanced precision and efficiency involves incorporating advanced techniques that significantly boost machining accuracy. A comprehensive review of wire electrical discharge machining (WEDM) highlights its capability to produce components with varying hardness, making it an essential process in industries that demand high precision. Recent studies indicate that employing optimized process parameters can lead to superior surface integrity and kerf characteristics, particularly when dealing with materials like Ti6Al4V. For instance, the use of multi-objective optimization techniques, such as the response surface methodology combined with advanced algorithms, has demonstrated marked improvements in the performance of EDM processes across different alloys.

Optimizing EDM machine parts for enhanced precision and efficiency involves incorporating advanced techniques that significantly boost machining accuracy. A comprehensive review of wire electrical discharge machining (WEDM) highlights its capability to produce components with varying hardness, making it an essential process in industries that demand high precision. Recent studies indicate that employing optimized process parameters can lead to superior surface integrity and kerf characteristics, particularly when dealing with materials like Ti6Al4V. For instance, the use of multi-objective optimization techniques, such as the response surface methodology combined with advanced algorithms, has demonstrated marked improvements in the performance of EDM processes across different alloys.

Furthermore, electroforming-based micro-texturing has emerged as a groundbreaking innovation in EDM, allowing for the fabrication of microtextured electrodes. These advancements enable enhanced surface engineering, which is critical for applications requiring intricate designs and precise features. Notably, research involving shape memory alloys (SMAs) underlines the importance of electro-discharge machining in achieving desired microstructural properties. As industries increasingly adopt these sophisticated techniques, the ability to fine-tune EDM parameters will be pivotal in realizing improved efficiencies and accuracy in part manufacturing, ultimately advancing overall production capabilities.

In the world of Electrical Discharge Machining (EDM), performance monitoring has become crucial for enhancing precision and efficiency. Recent studies suggest that implementing advanced software solutions can significantly improve machine operation, with data analytics showing that predictive maintenance can reduce downtime by up to 30% (Industry Week, 2021). By utilizing real-time data monitoring systems, operators can track vital parameters such as voltage, current, and tool wear, allowing for immediate adjustments that optimize machining processes.

Furthermore, a report by the American Society of Mechanical Engineers (ASME) highlights that integrating IoT technologies with EDM machines leads to a 25% increase in overall equipment effectiveness (OEE). This integration enables seamless communication between machines and software platforms, facilitating better analysis of performance trends and anomalies. As manufacturing demands shift towards precision engineering, embracing advanced technology in EDM not only streamlines operations but also contributes to maintaining competitive advantages in the industry.

| Parameter | Current Value | Optimal Value | Improvement (%) |

|---|---|---|---|

| Electrode Material Conductivity | 70 S/m | 80 S/m | 14.29% |

| Pulse Duration (µs) | 250 | 200 | 20.00% |

| Flushing Pressure (bar) | 1.5 | 2.0 | 33.33% |

| Machine Temperature (°C) | 70 | 60 | 14.29% |

| Surface Finish (Ra) | 1.0 | 0.5 | 50.00% |