Mold stamping has emerged as a pivotal technology in modern manufacturing, playing a crucial role in enhancing efficiency and reducing production costs. According to a report by Technavio, the global mold stamping market is expected to grow by USD 5.37 billion from 2021 to 2025, reflecting a compound annual growth rate (CAGR) of 6.69%. This growth highlights the increasing reliance on mold stamping techniques across various industries, such as automotive, electronics, and consumer goods, where precision and speed are paramount.

The advantages of mold stamping, including its ability to produce complex shapes with high accuracy and minimal waste, position it as a critical component in achieving lean manufacturing goals. The 2021 Global Manufacturing Outlook by Deloitte indicates that companies adopting advanced manufacturing technologies, including mold stamping, have reported up to 30% improvements in operational efficiency. This data underscores the necessity of integrating mold stamping processes into operations to optimize productivity and foster innovation.

Furthermore, as companies strive to meet shifting consumer demands and sustainability goals, mold stamping offers an environmentally friendly solution by significantly reducing material consumption and energy usage. According to the National Association of Manufacturers, implementing efficient manufacturing practices can lead to a 20-25% reduction in production costs. Therefore, understanding and leveraging the full potential of mold stamping is essential for manufacturers aiming to thrive in today's competitive landscape.

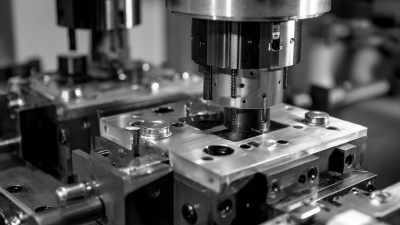

Mold stamping is a critical process in modern manufacturing that involves shaping materials, typically metals or plastics, into desired forms using specially designed molds. This technique is essential for producing high-volume, precise components with consistent quality. By applying pressure to the material within the mold, manufacturers can achieve complex shapes, reducing waste and ensuring efficient use of resources. The significance of mold stamping transcends mere production; it plays a pivotal role in enhancing the overall efficiency of manufacturing operations.

Understanding the importance of mold stamping highlights its contributions to cost-effectiveness and speed in production. By enabling mass production of identical parts, mold stamping minimizes the need for extensive manual labor and decreases the likelihood of defects, leading to lower operational costs. Additionally, the quick turnaround times associated with the mold stamping process allow manufacturers to respond swiftly to market demands and adapt to changing trends. This adaptability not only strengthens a company’s competitive edge but also underscores the integral role of mold stamping in the evolution of efficient manufacturing processes.

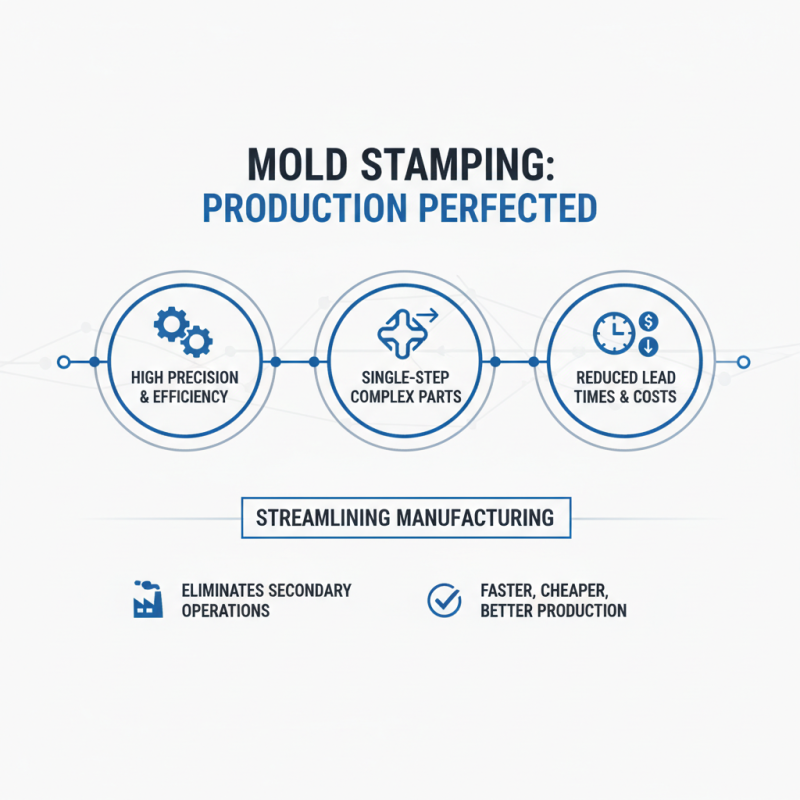

Mold stamping plays a pivotal role in streamlining production processes across various manufacturing industries. By providing high precision and efficiency in parts creation, mold stamping eliminates the need for extensive secondary operations. This method allows manufacturers to produce complex shapes and intricate designs in a single step, minimizing the time and resources typically required in traditional fabrication methods. The result is a significant reduction in lead times and operational costs, which are crucial factors in maintaining a competitive edge in today’s fast-paced market.

Moreover, the automation and consistency offered by mold stamping enhance overall productivity. With the ability to create large quantities of identical parts quickly, manufacturers can scale up their operations without compromising on quality. This not only leads to improved throughput but also ensures that products meet stringent quality standards, facilitating smoother transitions through the supply chain. As a consequence, businesses can respond more rapidly to changing demands and maintain flexibility in their production schedules, which is essential for adapting to market trends and consumer needs.

Mold stamping has emerged as a transformative manufacturing technique that significantly enhances production efficiency compared to traditional methods. One of the most notable advantages of mold stamping is its ability to achieve high-volume output with consistent precision. According to recent industry reports, manufacturers utilizing advanced mold stamping technologies can increase their production rates by up to 40% compared to conventional stamping methods. This improvement not only reduces lead times but also allows for greater scalability in operations, making it an attractive option for companies looking to meet growing market demands.

Moreover, mold stamping offers superior material yield and waste reduction, further contributing to its efficiency. Traditional manufacturing methods often lead to a higher scrap rate, with studies indicating that such processes may generate up to 20% more waste material. Conversely, mold stamping techniques can optimize material usage, resulting in waste rates as low as 5%. This decrease in scrap not only benefits the environment but also lowers material costs for manufacturers, allowing them to allocate resources more effectively. As industries increasingly prioritize sustainability, the adoption of mold stamping becomes not only a financial decision but also a strategic move toward eco-friendly manufacturing practices.

Mold stamping is becoming increasingly vital across several key industries, enhancing productivity and precision in manufacturing. Among the primary sectors leveraging mold stamping techniques are automotive, electronics, and aerospace. According to a 2022 report from IBISWorld, the automotive industry alone has seen a growth of over 3.5% annually in mold stamping usage, largely driven by the demand for lightweight and complex components that precision stamping can deliver.

Electronics manufacturers also benefit significantly; a study by the Semiconductor Industry Association highlighted that innovative stamping processes can reduce production time by nearly 25%, directly influencing the speed to market for new electronic devices.

Electronics manufacturers also benefit significantly; a study by the Semiconductor Industry Association highlighted that innovative stamping processes can reduce production time by nearly 25%, directly influencing the speed to market for new electronic devices.

As mold stamping techniques evolve, industries that embrace these methods can optimize their manufacturing efficiencies. Aerospace, for instance, relies heavily on precision parts that are not only lightweight but also robust. A report from the Aerospace Industries Association indicates that advanced stamping techniques contribute to weight reductions of up to 15% on average in aircraft components, which is crucial for fuel efficiency and overall performance.

Tips: To maximize the benefits of mold stamping, manufacturers should invest in training for their workforce on the latest stamping technologies. Additionally, maintaining up-to-date machinery can significantly reduce downtime and lead to greater long-term savings. Implementing regular quality checks during the stamping process can also ensure that any issues are identified early, maintaining production efficiency and product integrity.

Mold stamping technology has been undergoing significant advancements, driven by the need for faster production cycles and enhanced precision in manufacturing. Recent reports indicate that the global mold market is projected to reach USD 39.8 billion by 2027, growing at a CAGR of 4.1% from 2020. This growth is spurred by innovations in materials and methods, such as the adoption of 3D printing in mold design, which allows for greater complexity and reduced lead times. Furthermore, the integration of smart manufacturing technologies like IoT and AI into mold stamping processes is enhancing real-time data analytics, leading to optimized operations and reduced waste.

Future trends indicate a shift toward hybrid mold stamping techniques that combine traditional stamping with additive manufacturing. According to a study published by industry analysts, this hybrid approach can improve production efficiency by up to 30%, particularly in low-volume, high-variability contexts. Additionally, advancements in materials science are facilitating the development of lightweight yet durable mold materials, which are essential in industries like automotive and aerospace, where reducing weight is critical for performance and fuel efficiency. As industries strive for sustainability, innovations such as eco-friendly mold coatings and energy-efficient stamping machinery are also gaining traction, underscoring mold stamping technology's pivotal role in the future of efficient manufacturing processes.

| Dimension | Value | Trend |

|---|---|---|

| Production Time (hours per unit) | 1.5 | Decreasing |

| Material Waste (%) | 5 | Reducing |

| Energy Consumption (kWh per unit) | 2.0 | Stable |

| Lead Time (days) | 7 | Shortening |

| Defect Rate (%) | 1.2 | Decreasing |