The 2025 China 138th Canton Fair promises to be a pivotal event for the milling machining industry, showcasing the latest innovations and advancements that are driving market growth. As manufacturers and industry leaders gather at this renowned trade fair, they will present cutting-edge technologies and solutions that enhance efficiency, precision, and sustainability in milling machining processes. With the global manufacturing landscape evolving rapidly, this fair offers a unique opportunity for stakeholders to explore emerging trends, share insights, and network with key players. Market growth projections indicate a significant rise in demand for efficient milling machining techniques, underscoring the importance of this event in shaping the future of the industry. The Canton Fair will not only highlight current innovations but also set the stage for collaborations that could redefine milling machining practices in the years to come.

The upcoming 2025 Canton Fair is set to highlight the latest trends and innovations in milling machining, reflecting the sector's ongoing evolution toward automation and efficiency. With the global machine tool market projected to grow at a compound annual growth rate (CAGR) of 8.2%, reaching an estimated $200 billion by 2026, advancements in milling technologies are experiencing increasing demand. This fair serves as a platform where industry leaders will showcase cutting-edge solutions that enhance production capabilities, reduce waste, and improve precision.

During the fair, visitors can expect to see a diverse array of milling machinery enhancements, including AI-integrated systems that streamline operations and predictive maintenance technologies that minimize downtime. Additionally, the ongoing focus on sustainability within the industry means that innovations will likely prioritize energy efficiency and eco-friendly materials. According to recent reports, nearly 70% of manufacturers are now investing in energy-efficient technologies, signaling a strong trend toward environmentally responsible production practices. The 2025 Canton Fair will undoubtedly provide invaluable insights into these transformative shifts, attesting to the milling machining industry's pivotal role in shaping the future of manufacturing.

The impact of advanced technologies on milling machinery in 2025 is profound, showcasing significant enhancements in productivity across various industries. The integration of digital manufacturing technologies is revolutionizing how milling processes are implemented, leading to increased efficiency and reduced operational costs. As industries adopt these innovations, the milling sector is likely to see a surge in demand, particularly within the flour and rice milling markets, which are projected to achieve substantial growth in the coming years.

With Africa emerging as the fastest-growing market for flour milling machines, the global market for milling technologies is poised for an impressive rise. Analysts predict the flour milling machines market will expand from USD 0.9 billion in 2025 to USD 1.6 billion by 2032, and the rice milling machine sector is also expected to reach USD 1.9 billion by 2035. These projections reflect a broader trend of increased reliance on advanced machinery, which enhances productivity and meets the rising demand for processed food products globally. As technology continues to evolve, the milling industry is entering a new era marked by innovation and growth.

The milling machining industry in China is poised for significant growth, driven by increasing demand in various sectors such as construction, automotive, and aerospace. As showcased at the 2025 Canton Fair, innovations in milling machining technologies will play a crucial role in enhancing manufacturing efficiency and precision. This growth is reflected in market projections, with the global machine tools market expected to expand from USD 134.96 billion in 2023 to USD 169.47 billion in the coming years, largely propelled by advancements in milling equipment and techniques.

Tips for manufacturers looking to capitalize on this growth include investing in state-of-the-art technology to boost production capabilities and reduce waste. Understanding the evolving needs of customers can help companies tailor their offerings, ensuring they remain competitive in a rapidly changing landscape. Furthermore, engaging in research and development can lead to groundbreaking solutions that meet the demands of a diverse market.

To navigate this competitive environment effectively, collaboration with industry partners can provide valuable insights and enhance innovation. Establishing a strong network within the milling machinery sector will not only aid in sharing best practices but also open up new opportunities for joint ventures and partnerships that can drive future growth.

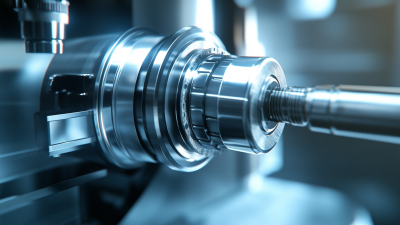

The 2025 China 138th Canton Fair is set to highlight significant advancements in milling machining, showcasing a range of innovative products from key exhibitors in the industry. Leading companies such as DMG Mori and Makino will present their latest technologies that focus on improving efficiency and precision. According to a recent report by Mordor Intelligence, the global milling machine market is expected to grow at a CAGR of 6.5% from 2023 to 2028, driven by increasing demand for high-quality manufacturing processes across various sectors.

Notable innovations expected at the fair include advanced CNC milling machines equipped with AI-driven software, which can optimize machining parameters in real-time. Additionally, exhibitors will demonstrate eco-friendly milling solutions designed to reduce energy consumption and waste, aligning with the industry's push for sustainability. As the milling sector continues to evolve, the Canton Fair provides an essential platform for industry leaders to connect and showcase how these innovations can meet the demands of a rapidly changing market.

The milling machining sector is on the brink of transformation as it navigates the challenges and opportunities that will arise post-2025. With technological advancements accelerating, manufacturers are expected to adopt innovative machining methods that enhance precision and efficiency. However, challenges such as integrating new technologies into existing systems and the need for skilled labor remain significant hurdles. Companies must prioritize workforce training to bridge the skill gap created by rapid advancements in automation and artificial intelligence.

Furthermore, sustainability will play a pivotal role in shaping the future landscape of milling machining. As environmental regulations tighten, industries will need to reevaluate their processes and materials, focusing on green manufacturing practices. This shift not only presents a challenge, but also offers opportunities for businesses that can innovate within these parameters. The market's increasing demand for sustainable solutions will drive new product development, encouraging manufacturers to explore eco-friendly materials and waste reduction strategies that align with global sustainability goals.