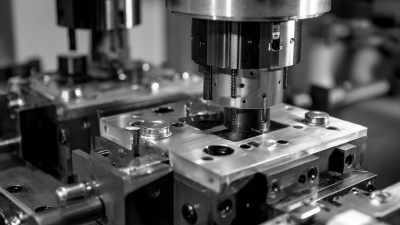

In the intricate world of manufacturing, "Tool And Die Design" stands as a cornerstone for achieving unparalleled precision and efficiency. Mastering the art and science behind tool and die design techniques not only enhances production quality but also optimizes the entire manufacturing process. This guide delves into the essential strategies and skills necessary to excel in this specialized field. From understanding the fundamental principles of tool geometry to adopting advanced materials and technologies, we will explore how these elements contribute to the creation of high-performance tools and dies. By adopting best practices and innovative approaches, designers can significantly reduce costs and lead times while maintaining the highest standards of accuracy. Whether you are a seasoned professional or just starting out, this comprehensive overview aims to equip you with the knowledge needed to elevate your tool and die design capabilities to new heights.

Understanding the fundamentals of tool and die design principles is crucial for anyone looking to enhance precision and efficiency in manufacturing processes. Tool and die design involves creating the specialized tools used to shape and cut materials, and mastering these principles can significantly impact the quality of the final product. A solid foundation in materials science, mechanics, and geometric tolerances is essential, as it enables designers to develop tools that meet specific operational requirements.

Tips: When starting out, focus on learning the common design conventions used in the industry. Familiarize yourself with CAD software, which allows for precise modeling and simulation of tools and dies before production. Additionally, always consider manufacturability and serviceability during the design process to minimize costs and optimize performance.

Another important principle is the aspect of interchangeability. Designing tools and dies that can be easily replaced or repaired ensures minimal downtime and boosts efficiency. Pay attention to create components that adhere to standardized dimensions and features, thus streamlining both the manufacturing and maintenance processes. Remember, attention to detail and continuous improvement in your designs will lead to enhanced outcomes in your tool and die projects.

In the realm of tool and die design, the emergence of advanced CAD software has revolutionized the approach to precision and efficiency. These sophisticated tools enable designers to create intricate models with remarkable accuracy, significantly reducing the time spent on revisions and prototyping. According to a report by the American Society of Mechanical Engineers (ASME), the integration of CAD technology has led to a 30% increase in design productivity and a 25% decrease in manufacturing lead times. This highlights the vital role that cutting-edge software plays in shaping modern tooling processes.

Furthermore, the capabilities of advanced CAD software extend beyond basic design functionalities. Features like parametric modeling and simulation allow for exhaustive testing of designs under various conditions, ensuring that the end product meets stringent quality standards. A study by the National Institute of Standards and Technology (NIST) estimates that organizations utilizing advanced CAD tools can achieve a reduction in production costs by up to 20%. As manufacturing industries increasingly adopt these digital solutions, the synergy between precision tool design and efficiency becomes evident, setting a new benchmark for excellence in the field.

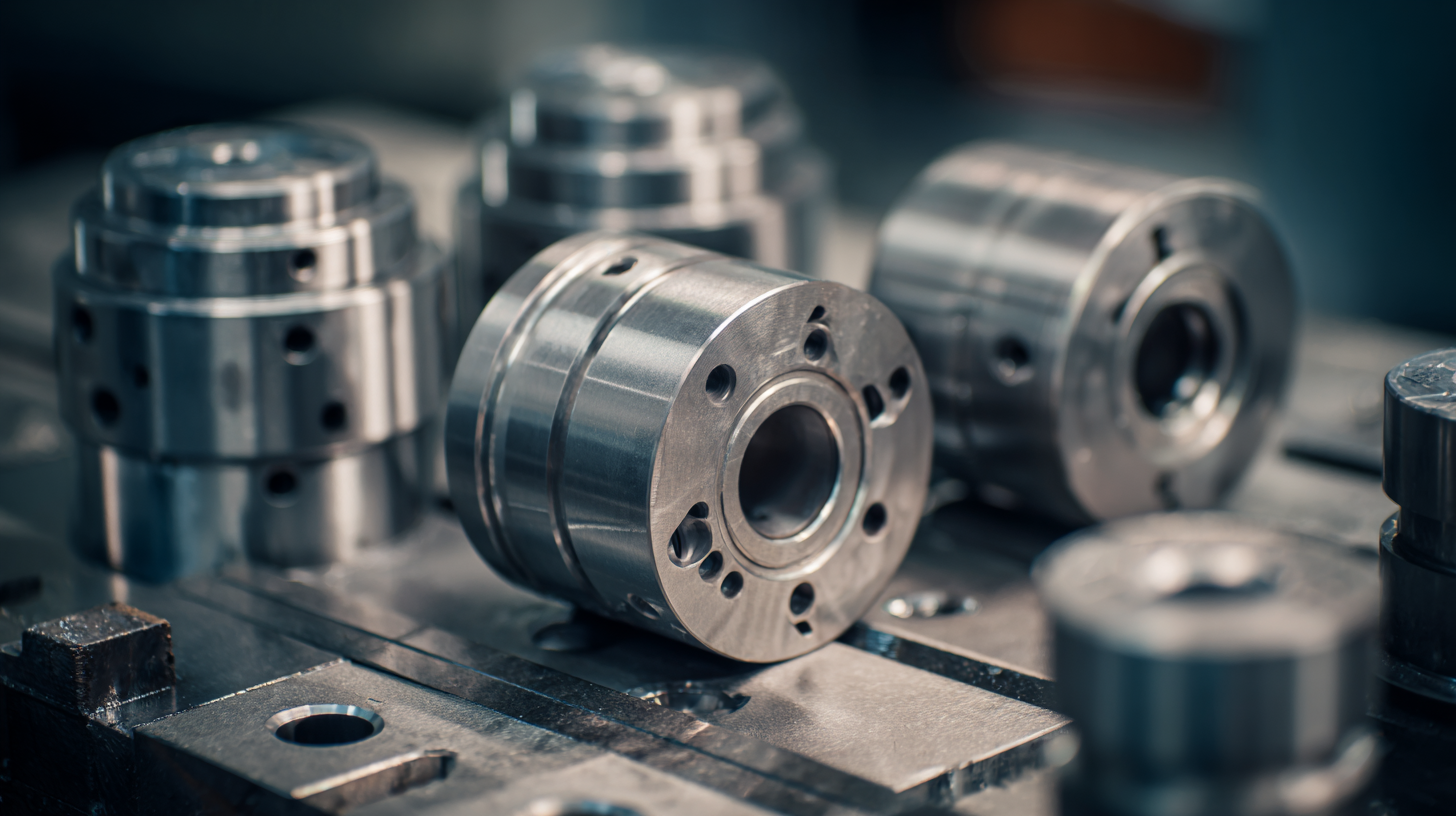

In the realm of tool making, mastering material selection and heat treatment techniques is crucial for enhancing precision and efficiency. Selecting the right materials not only affects the durability of the tools but also their performance in various applications. High-carbon steels, tool steels, and alloy steels are commonly utilized due to their excellent hardness and wear resistance. However, understanding the specific requirements of the intended use will guide you in selecting the best material for each tool design.

Heat treatment plays a pivotal role in achieving the desired properties of the selected materials. Processes such as quenching and tempering can significantly improve the hardness and toughness of the tool. As the market for rapid heat treatment systems is expected to grow at a CAGR of 3.9% from 2025 to 2033, integrating these systems into your tool-making processes could offer substantial benefits. These systems enhance the efficiency of heat treatment, allowing for faster processing times without compromising on quality.

**Tips for Success:**

- Always conduct thorough material research to match the characteristics of the tool with the expected operational environment.

- Implement rapid heat treatment methods to streamline your production process and achieve consistent results in tool hardness and performance. Use thermal cycles that elevate the uniformity of treatments, thus minimizing the risk of defects.

| Techniques | Material Selection | Heat Treatment Process | Expected Benefits |

|---|---|---|---|

| CNC Machining | Tool Steel (D2) | Quenching and Tempering | High Precision and Durability |

| Wire EDM | Carbide | Sintering | Exceptional Finish and Edge Retention |

| 3D Printing | Inconel | Age Hardening | Complex Shapes and Lightweight Constructs |

| Surface Grinding | Alloy Steel (4140) | Normalizing | Improved Surface Finish and Hardness |

| Milling and Routing | High Carbon Steel | Carburizing | Enhanced Wear Resistance |

Implementing efficient workflow strategies in tool and die production is crucial for enhancing precision and operational efficiency. First, adopting lean manufacturing principles can significantly minimize waste and optimize resource utilization. By streamlining processes and reducing unnecessary steps, manufacturers can focus more on value-added activities. For instance, techniques such as 5S (Sort, Set in order, Shine, Standardize, Sustain) help organize workspaces, improving productivity and safety while enabling quicker access to tools and materials.

Additionally, leveraging technology can further refine these workflows. Implementing computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allows for greater accuracy in designs and smoother transitions from design to production. These technologies facilitate real-time collaboration among teams, which minimizes miscommunication and errors. Adopting automation for repetitive tasks can also free up skilled workers to engage in more complex problem-solving activities, ultimately leading to better product quality and reduced lead times in tool and die production.

Quality control and testing are crucial components in tool and die design processes, as they directly impact the precision and efficiency of the final products. Implementing best practices for quality control begins with establishing clear standards and specifications at the outset of the design phase. This ensures that all team members are aligned on expectations, which helps in minimizing errors during production. Regular audits and inspections throughout the design and manufacturing processes can further facilitate the identification and correction of potential issues before they escalate into significant problems.

In addition to robust quality control measures, effective testing procedures are essential in validating the performance of tooling designs. Employing advanced testing methods, such as digital simulation and prototype testing, allows designers to assess the functionality of tools in a controlled environment, optimizing designs before mass production. Furthermore, incorporating feedback loops into the testing phase ensures continuous improvement, where insights gained from testing can inform future design iterations. By prioritizing quality control and rigorous testing, tool and die designers can achieve greater precision and efficiency, ultimately enhancing the overall quality of the tools produced.

This chart illustrates the average precision and efficiency metrics achieved through various tool and die design techniques. The data reflects the outcomes of different best practices applied during the design process, showing their impact on quality control and testing.