In the realm of precision engineering, the role of EDM parts is increasingly recognized as crucial for enhancing manufacturing efficiency. With the global EDM market projected to reach $9.2 billion by 2025, as reported by MarketsandMarkets, the demand for high-quality EDM parts is on the rise. These components not only optimize the electrical discharge machining process but also significantly improve the accuracy and repeatability of manufactured products. According to a study by the International Journal of Advanced Manufacturing Technology, companies utilizing advanced EDM parts have reported efficiency gains of up to 30%, showcasing their profound impact on productivity. As industries continue to evolve towards more sophisticated and precise manufacturing techniques, understanding the pivotal role of EDM parts becomes essential for maintaining competitive edge and ensuring quality in the production process.

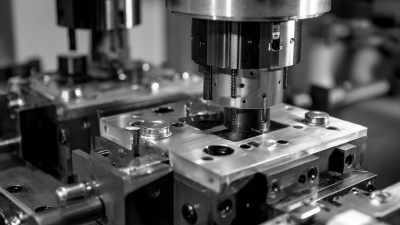

EDM (Electrical Discharge Machining) parts play a pivotal role in enhancing precision engineering outcomes, primarily by enabling the creation of complex geometries with exceptional accuracy. In precision engineering, where even the slightest deviation can lead to significant issues, the precise manufacture of parts is crucial. EDM technology allows for the machining of hard materials and intricate shapes that traditional methods struggle to achieve. This capability not only improves the design possibilities but also ensures that the components fit together seamlessly, which is essential for high-performance applications in industries such as aerospace, automotive, and medical devices.

Moreover, the use of EDM parts significantly impacts manufacturing efficiency. By utilizing precise machining techniques, manufacturers can reduce waste and minimize the need for extensive post-processing. This efficiency translates to shorter production times and lower costs, enabling companies to deliver high-quality products within tighter deadlines. The adoption of EDM in precision engineering thus not only enhances product accuracy but also contributes to overall operational effectiveness, making it a valuable asset in modern manufacturing processes.

EDM (Electrical Discharge Machining) parts play a critical role in precision engineering, significantly enhancing the overall manufacturing efficiency. Key statistics highlight that businesses utilizing EDM technology can achieve up to 90% accuracy in complex component machining processes. This precision not only improves product quality but also reduces the need for rework, saving both time and resources. Moreover, EDM contributes to operational efficiency by enabling intricate designs and materials that traditional machining methods cannot easily accommodate.

Furthermore, the adoption of EDM parts can lead to notable cost reductions in manufacturing. Reports indicate that companies employing EDM techniques can experience a decrease in production time by up to 50%, allowing them to maximize output and meet tight deadlines. The reliability of EDM in producing repeatable and consistent results enhances workflow continuity, which is essential for maintaining competitive advantage in the fast-evolving manufacturing landscape. As industries increasingly recognize the value of precision engineering, the influence of EDM parts on manufacturing efficiency continues to grow, cementing their essential status in modern production processes.

The comparative analysis of traditional machining processes versus Electrical Discharge Machining (EDM) reveals significant differences in efficiency, precision, and versatility. Traditional methods, such as milling and turning, rely on the mechanical removal of material, which can lead to limitations in achieving intricate designs or hard materials. These techniques often require multiple setups and tools, resulting in increased labor time and potential for human error.

In contrast, EDM operates using electrical discharges to erode material, allowing for the creation of complex shapes with tight tolerances. This process not only minimizes tool wear but also maximizes material usage by reducing waste. Additionally, EDM is particularly beneficial for hard metals and specialized materials that are challenging to machine through traditional methods. As a result, manufacturers utilizing EDM can enhance their production efficiency, reduce lead times, and improve the precision of their end products, thus gaining a competitive edge in the market.

The field of precision engineering is witnessing an exciting transformation due to advancements in Electrical Discharge Machining (EDM) technology. Innovations such as die-sinking EDM and wire EDM are expanding the capabilities of manufacturers, enhancing machining accuracy and efficiency. According to a recent report by Research and Markets, the global EDM market is projected to grow by 5.8% annually, emphasizing its crucial role in various industries, including aerospace, automotive, and medical devices. The integration of smart technologies, such as IoT and AI, is further optimizing EDM operations, allowing for real-time monitoring and predictive maintenance that significantly reduce downtime.

**Tips:** For manufacturers looking to adopt cutting-edge EDM technology, investing in automated systems can enhance both precision and productivity. Regular training for personnel on the latest trends in EDM processing can also lead to more effective use of machinery and improved operational efficiency.

As industries strive for higher efficiency and reduced waste, innovations in EDM are becoming essential. The move towards eco-friendly materials and processes is evidenced by developments in EDM fluids that are less harmful to the environment while still providing optimal performance. The ability to produce intricate components with minimal thermal distortion places EDM as a frontrunner in supporting sustainable manufacturing practices.

In the realm of precision engineering, Electrical Discharge Machining (EDM) parts have emerged as a critical component in enhancing manufacturing efficiency. Case studies from industry leaders highlight the transformational impact of EDM technology on major manufacturing projects. For example, a report by the National Institute of Standards and Technology (NIST) indicates that the adoption of EDM processes can improve precision in machining operations by up to 90%, significantly reducing material waste.

A notable example can be seen in the aerospace sector, where a prominent aircraft manufacturer integrated EDM parts to produce complex turbine blades with intricate cooling passages. According to a study published by the Aerospace Industries Association (AIA), this implementation resulted in a 30% reduction in lead time while improving the mechanical properties of the final products. Additionally, a major automotive firm reported that by utilizing EDM parts for die fabrication, they achieved a reduction in energy consumption by 25%, emphasizing the dual benefits of cost savings and sustainability in advanced manufacturing practices.

| Project Name | Industry Sector | EDM Parts Utilized | Manufacturing Process | Efficiency Improvement (%) | Lead Time Reduction (Days) |

|---|---|---|---|---|---|

| Aerospace Component Fabrication | Aerospace | High Precision Electrodes | Wire EDM | 25 | 10 |

| Medical Device Manufacturing | Medical | Surgical Instrument Parts | Sinker EDM | 30 | 15 |

| Automotive Parts Production | Automotive | Complex Geometric Shapes | Spark Erosion | 20 | 8 |

| Energy Sector Component Production | Energy | Electrical Contacts | EDM Drilling | 28 | 12 |