As we look towards 2025, the landscape of precision machining part manufacturing is poised for significant transformation, driven by advancements in technology and shifting global demands. According to a recent report by Research and Markets, the global precision machining market is expected to reach $813 billion by 2025, growing at a CAGR of 6.1%. This growth is largely attributed to the increasing demand for high-quality components in industries such as aerospace, automotive, and medical devices. Furthermore, China's role as a leader in manufacturing continues to expand, emphasizing the country's ability to produce high-quality precision machining parts that meet international standards. As manufacturers adapt to these trends, the ability to leverage innovative technologies and maintain stringent quality controls will be essential in thriving within this competitive landscape.

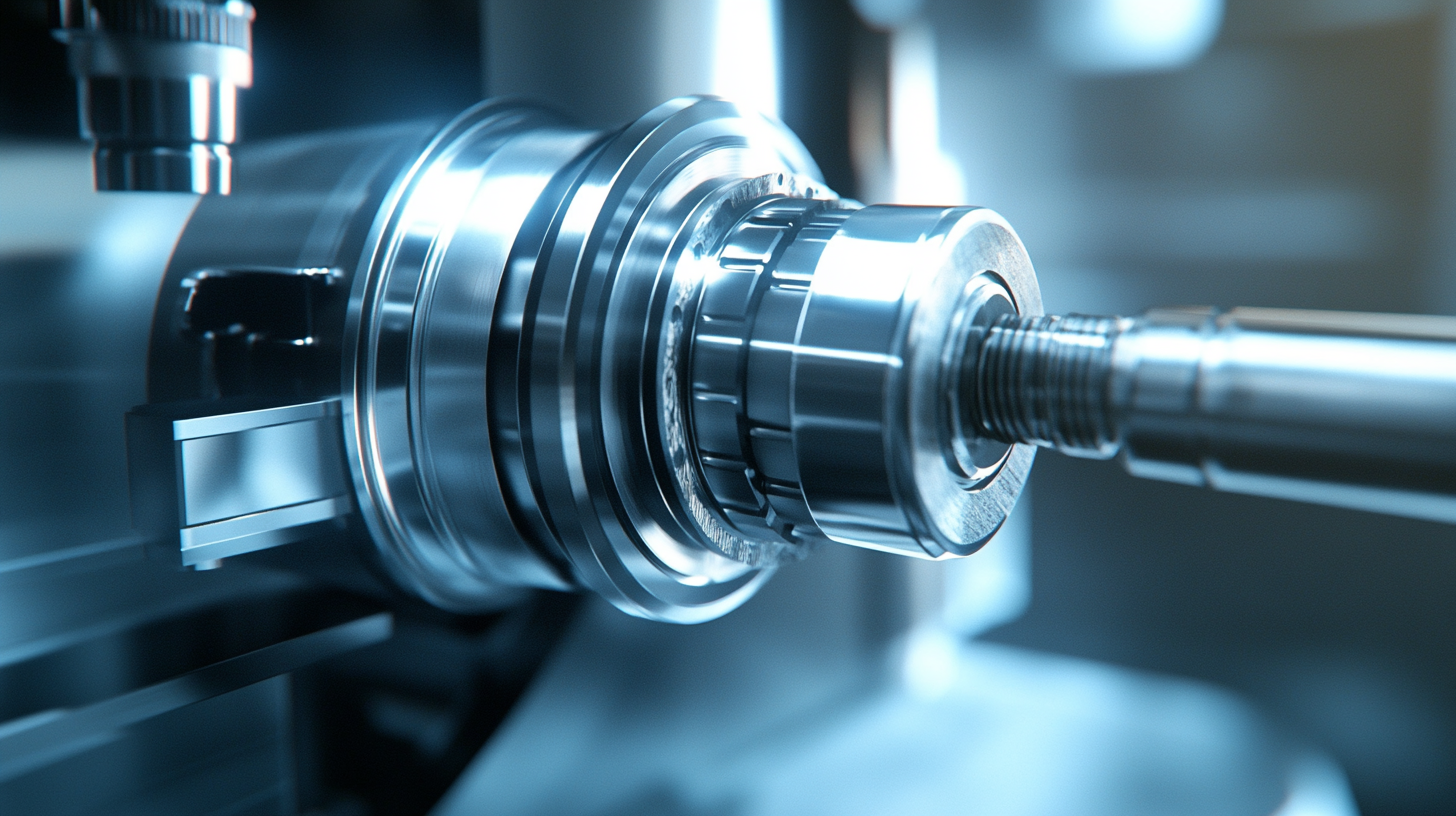

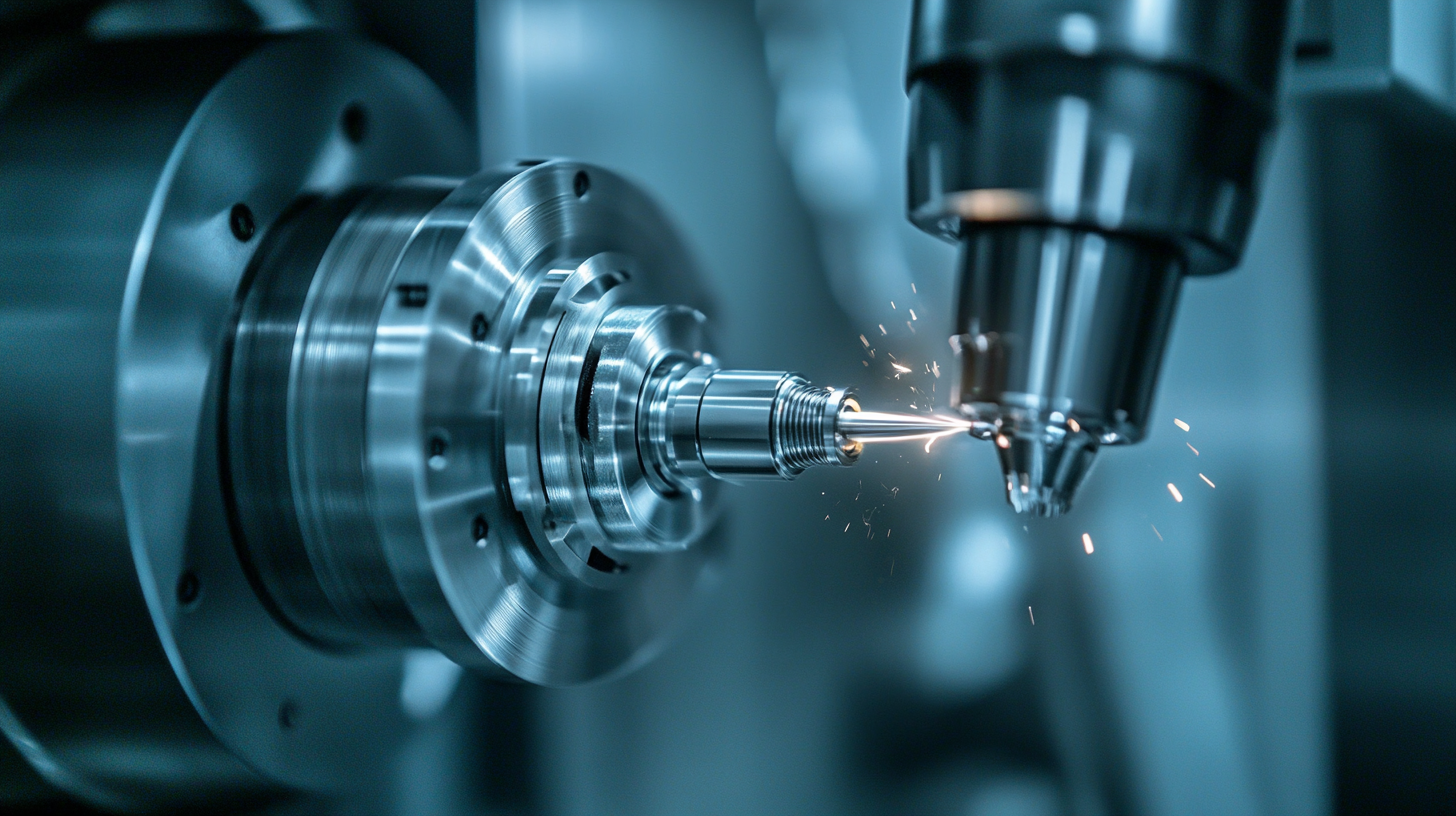

As we approach 2025, the landscape of precision machining is poised for transformative changes driven by emerging technologies. Digitalization and automation are set to redefine manufacturing processes, making them more efficient and precise. Advanced machining techniques, such as additive manufacturing and CNC machining, are being enhanced through data analytics and machine learning, enabling real-time adjustments and predictive maintenance. These innovations not only improve the speed and accuracy of production but also reduce waste and increase overall operational efficiency.

Furthermore, the integration of IoT (Internet of Things) in precision machining is creating a connected ecosystem where machines communicate and share data, leading to smarter decision-making processes. With the rise of smart factories, manufacturers can monitor equipment health, optimize workflows, and enhance product quality through seamless connectivity. Additionally, sustainable practices are gaining traction, with technologies aimed at reducing carbon footprints and resource consumption becoming essential components of the industry's future. As these trends unfold, precision machining will not only evolve but also become a critical player in the broader movement towards smarter, greener manufacturing solutions.

The landscape of precision machining is on the cusp of significant evolution, driven by advancements in materials technology. As we look towards 2025, several key materials are set to revolutionize the production of precision machining parts. Among these, high-performance alloys such as titanium and advanced steel composites are gaining traction due to their remarkable strength-to-weight ratios and durability. These materials not only enhance the performance of machined components but also allow for more complex geometries that are essential in modern applications.

In addition to traditional metals, the rise of advanced polymers and composite materials is reshaping precision machining capabilities. These lightweight, corrosion-resistant materials offer unique advantages in industries such as aerospace and medical technology, where precision and reliability are paramount. Moreover, innovations in additive manufacturing techniques are enabling the creation of intricate designs that were previously impossible with conventional machining methods. As these materials and technologies continue to advance, they promise to push the boundaries of what is feasible in precision machining, leading to smarter and more efficient production processes.

| Material Type | Key Properties | Applications | Expected Growth 2025 (%) |

|---|---|---|---|

| Titanium Alloys | High strength-to-weight ratio, corrosion-resistant | Aerospace, Biomedical | 15% |

| Carbon Fiber Composites | Lightweight, high tensile strength | Automotive, Sports Equipment | 20% |

| Aluminum Alloys | Lightweight, good thermal conductivity | Electronics, Transportation | 10% |

| Stainless Steel | Corrosion-resistant, durable | Food Industry, Medical Devices | 8% |

| High-Performance Polymers | Chemical resistance, high thermal stability | Aerospace, Electronics | 25% |

The precision machining industry is undergoing a significant transformation as sustainability practices gain traction. According to a report by the Precision Machining Association, nearly 70% of manufacturers are actively implementing eco-friendly practices. This shift is driven by both regulatory pressure and a growing awareness of the environmental impact of machining processes, which traditionally rely on energy-intensive operations and generate substantial waste.

In 2025, we can expect that sustainable practices such as energy-efficient machinery and waste reduction strategies will become mainstream. Data from the National Institute of Standards and Technology indicates that adopting greener technologies can reduce energy costs by up to 30%. Furthermore, precision machinists are increasingly utilizing recycled materials and implementing closed-loop systems to minimize waste, fostering a circular economy within the industry. This commitment not only meets compliance requirements but also enhances brand reputation, particularly among environmentally conscious consumers. The integration of sustainability into precision machining is not just a trend; it is becoming a critical component of operational excellence for future industry leaders.

This graph illustrates the projected importance levels of various trends in the precision machining industry by 2025, focusing on sustainability practices, technological advancements, material efficiency, cost reduction, and customer demand. Each trend is rated on a scale from 1 to 10, indicating its significance for industry stakeholders.

The landscape of precision machining is set to undergo significant transformation by 2025, driven primarily by automation trends that are revolutionizing manufacturing processes. As industries increasingly adopt CNC machines, they experience heightened efficiency and reduced lead times. This technological evolution not only improves production rates but also enhances the quality of precision parts, catering to a growing demand across various sectors.

The landscape of precision machining is set to undergo significant transformation by 2025, driven primarily by automation trends that are revolutionizing manufacturing processes. As industries increasingly adopt CNC machines, they experience heightened efficiency and reduced lead times. This technological evolution not only improves production rates but also enhances the quality of precision parts, catering to a growing demand across various sectors.

Tips for companies looking to invest in automation include prioritizing the integration of smart technologies. Embracing Industry 4.0 principles can provide manufacturers with valuable data insights, allowing for more informed decision-making and optimized production workflows. Additionally, focusing on training staff to work alongside automated systems can ensure a smooth transition and maximize the benefits of technological advancements.

Moreover, the precision parts market is projected to witness robust growth, with a compound annual growth rate (CAGR) of 9.43% from 2023 to 2029, potentially reaching USD 403.22 billion by 2029. Companies should consider exploring advanced tooling solutions that can complement their automated systems, ultimately leading to better product outcomes and a stronger competitive position in the market.

As we approach 2025, the landscape of precision machining is set to evolve dramatically, driven by advancements in technology and the increasing demand for customization. The Future of Jobs Report 2023 highlights that 85 million jobs may shift due to the proliferation of artificial intelligence and automation. Companies must prepare by adopting future-ready machining techniques that integrate these technologies seamlessly.

**Tips:** When considering new machining techniques, focus on developing a workforce skilled in AI and data analysis. Encourage training programs that emphasize versatility and adaptability, as the skill sets required in the industry are changing rapidly.

Furthermore, organizations should evaluate their readiness for AI adoption. The report indicates that while employees express enthusiasm for AI, many companies still lack the necessary infrastructure. Investing in advanced technologies like predictive analytics and smart manufacturing systems is crucial in this transition.

**Tips:** Begin with a thorough assessment of existing technology and capabilities. Identify gaps and potential improvements to ensure that your organization is on the cutting edge of precision machining innovations.