In the fast-paced world of precision manufacturing, the performance of an EDM (Electrical Discharge Machining) machine is paramount. To ensure optimal operations, it is crucial to focus on the essential EDM machine parts that directly impact efficiency, accuracy, and longevity of the machinery. Whether you are a seasoned professional or a newcomer in the field, understanding these critical components can make a significant difference in achieving desired results.

This article will explore the top 10 essential EDM machine parts that every operator should be familiar with. From the intricacies of the electrode to the nuances of the control systems, each component plays a vital role in the overall functionality of the EDM machine. By delving into the specifics of these parts, users can gain insights into best practices for maintenance and troubleshooting, ensuring that their machines operate at peak performance. Investing in the right EDM machine parts not only enhances productivity but also extends the lifespan of the equipment, paving the way for successful machining processes.

When it comes to achieving high efficiency in Electrical Discharge Machining (EDM), understanding the essential components of EDM machines is crucial. Various studies indicate that the performance of an EDM machine can significantly improve with the right combination of parts. Key components such as the power supply unit, electrode holder, and dielectric fluid reservoir play pivotal roles in ensuring optimal functioning and efficiency. For instance, a well-calibrated power supply can affect machining precision and speed, as highlighted in a report by the International Journal of Advanced Manufacturing Technology, where a 20% increase in overall productivity was recorded simply by optimizing the power supply settings.

Another critical element is the electrode itself. The choice of materials used for electrodes can directly influence machining quality and wear rate. The industry standard suggests that using copper-tungsten electrodes can increase machining efficiency by up to 30% compared to traditional brass electrodes. Proper maintenance of these electrodes, along with the dielectric fluid's quality, is also essential to minimize downtime and maintain consistent performance.

Tips for Maintaining EDM Efficiency: Regularly inspect and replace worn-out electrodes to prevent machining inaccuracies and downtime. Additionally, ensure that the dielectric fluid is clean and maintained at optimal levels, as this can lead to better thermal properties and increased tool life. Monitoring these components routinely can provide a significant boost in both efficiency and output quality.

Power supply units (PSUs) play a pivotal role in the performance of electrical discharge machining (EDM). As the heart of the EDM system, the PSU regulates and provides precise power to the machine, influencing machining accuracy and efficiency. Data suggests that a significant portion of machining errors—estimated at around 30%—can be attributed to fluctuations and inefficiencies in power supply. Therefore, investing in a high-quality PSU not only improves the stability of the discharge process but also enhances overall productivity and finished product quality.

When selecting a PSU for your EDM machine, consider its ability to maintain consistent voltage and current levels during the cutting process. Research indicates that a stable power output can yield improved surface finishes and reduced wear on electrodes. To optimize your EDM operation, ensure that the chosen PSU can handle the specific power requirements of your machine and the types of materials being machined. Additionally, look for units that offer advanced control features, allowing for real-time adjustments based on changing conditions.

Tips: Regular maintenance of your power supply unit is crucial. Check for wear and tear on connectors, and ensure that the cooling systems are functioning efficiently to avoid overheating. Implementing a preventive maintenance schedule can drastically extend the lifespan of the PSU, saving costs in the long run.

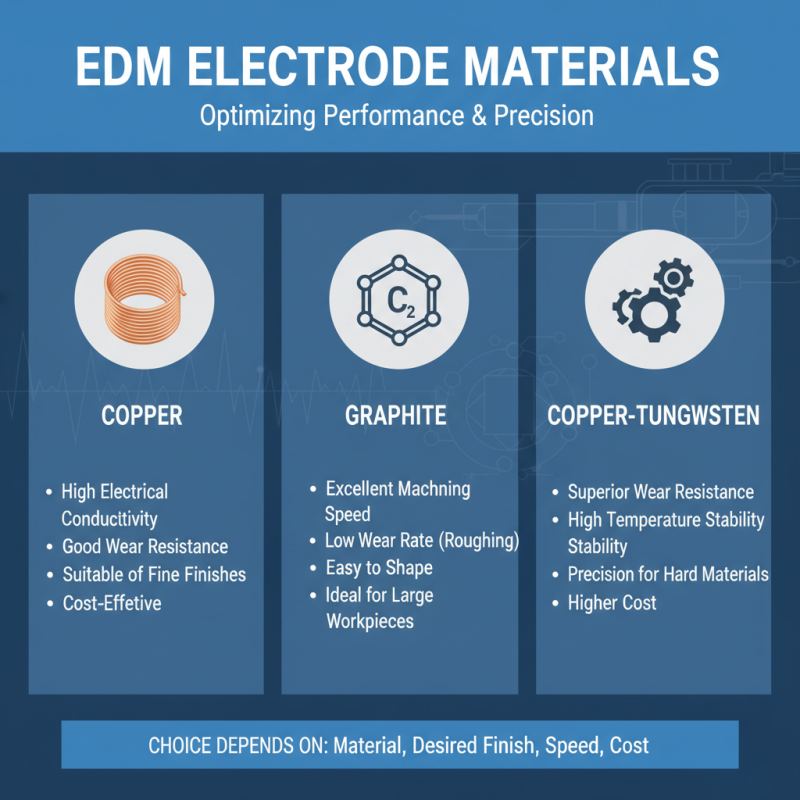

In the world of Electrical Discharge Machining (EDM), the choice of electrode materials is crucial for ensuring optimal performance and efficiency in machining processes. Electrode materials directly influence the quality of the machined surface, the precision of the dimensional tolerances, and the overall productivity of the operation. Common materials used for EDM electrodes include copper, graphite, and copper-tungsten alloys, each offering unique advantages and drawbacks depending on the application.

When selecting an electrode material, it's important to consider factors such as electrical conductivity, melting point, and wear resistance. For instance, graphite is favored for its excellent wear resistance and ability to withstand high temperatures, making it suitable for complex shapes and high-speed applications. On the other hand, copper provides superior electrical conductivity and is often chosen for applications requiring high machining speeds.

**Tips:**

- Regularly assess the wear of your electrodes to optimize tool life and reduce downtime.

- Experiment with different electrode materials for various projects to find the best balance of performance and cost.

- Ensure proper maintenance of your EDM machine to enhance the longevity and effectiveness of your electrode materials, ultimately leading to improved machining results.

In Electrical Discharge Machining (EDM), maintaining optimal temperature is crucial for ensuring the longevity of machine parts and achieving high precision in machining processes. Cooling systems play a significant role in dissipating heat generated during operations, which can otherwise lead to thermal expansion and adversely affect the accuracy of the machining process. According to a report from the International Journal of Advanced Manufacturing Technology, effective cooling can improve the tool life and machining efficiency by up to 30%, highlighting the importance of investing in robust cooling solutions.

Advanced cooling systems, such as closed-loop coolant circulation and temperature monitoring sensors, can significantly enhance the control over the machining environment. Research conducted by the American Society of Mechanical Engineers suggests that keeping the EDM tank at a stable temperature of around 20°C not only aids in maintaining the viscosity of the dielectric fluid but also improves the discharge uniformity, resulting in better surface finishes. Implementing sophisticated cooling strategies can prevent overheating and minimize wear on both the workpiece and the electrode, thus optimizing overall machine performance.

Advanced control systems play a critical role in enhancing precision in EDM machining. These systems are designed to improve the accuracy and reliability of the machining process by providing real-time data and feedback to operators. With sophisticated algorithms, they can adjust parameters such as voltage, pulse duration, and electrode positioning on-the-fly, ensuring that the machine operates at optimal settings throughout the machining cycle. This level of control not only minimizes material waste but also significantly increases the quality of the finished product.

Moreover, integrating advanced control systems with machine learning capabilities allows for predictive maintenance and adaptive machining strategies. By analyzing historical performance data, these systems can identify potential issues before they lead to machine downtime, thereby enhancing overall productivity. Additionally, the use of sensors and intelligent software can automate many aspects of the EDM process, enabling manufacturers to achieve consistent results and reduce the reliance on manual input. As the EDM landscape evolves, the focus on precision through advanced control systems will undoubtedly lead to greater efficiencies and innovations in the field.