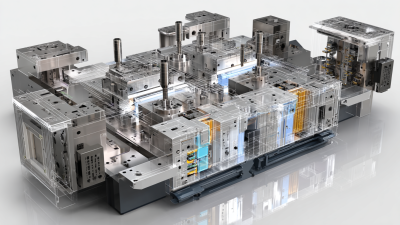

In the realm of manufacturing, the choice of Mould Insert types can significantly impact production efficiency and product quality. As industries strive to optimize their processes and reduce costs, understanding the various Mould Insert options available becomes essential. This blog delves into the key differences between Mould Insert types, exploring how each variant can influence the overall manufacturing workflow. By examining attributes such as material composition, thermal conductivity, and design features, we aim to equip manufacturers with the knowledge necessary to select the best Mould Insert that aligns with their operational goals. Ultimately, a deeper comprehension of Mould Inserts not only enhances manufacturing efficiency but also drives innovation in product development and output. Join us as we uncover the nuances that can lead to smarter manufacturing choices.

In the realm of manufacturing, the choice of Mould Insert types can significantly impact production efficiency and product quality. As industries strive to optimize their processes and reduce costs, understanding the various Mould Insert options available becomes essential. This blog delves into the key differences between Mould Insert types, exploring how each variant can influence the overall manufacturing workflow. By examining attributes such as material composition, thermal conductivity, and design features, we aim to equip manufacturers with the knowledge necessary to select the best Mould Insert that aligns with their operational goals. Ultimately, a deeper comprehension of Mould Inserts not only enhances manufacturing efficiency but also drives innovation in product development and output. Join us as we uncover the nuances that can lead to smarter manufacturing choices.

In modern manufacturing, the choice of mould inserts plays a crucial role in determining production efficiency and product quality. Mould inserts can be classified into several types, each offering distinct advantages depending on the specific application and production needs. For instance, standard inserts are typically utilized for high-volume runs where consistency is paramount, while modular inserts provide flexibility, allowing manufacturers to easily adjust designs for different products without significant downtime.

Another type worth noting is the custom mould insert, which is tailored to meet unique product specifications. These inserts can significantly enhance manufacturing capabilities by improving precision and reducing lead times. As the industry evolves, manufacturers are increasingly adopting a combination of these insert types to optimize their processes. By understanding the characteristics and applications of different mould inserts, manufacturers can make informed decisions that enhance efficiency, reduce costs, and improve overall product performance in an increasingly competitive market.

| Mould Insert Type | Material | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Standard Inserts | Steel | General machining | Cost-effective, easy to produce | Limited to standard designs |

| Custom Inserts | Aluminum | Complex geometries | Tailored for specific needs | Higher production costs |

| Interchangeable Inserts | Titanium | Variety of products | Flexibility in production | Maintenance can be complex |

| Hot Runner Inserts | Stainless Steel | High-volume production | Reduced cycle times | Higher initial setup cost |

| Cold Runner Inserts | Copper | Small batch runs | Lower cost for short runs | Less efficient for large volumes |

Understanding the various types of mould inserts is crucial for enhancing manufacturing efficiency. Each mould insert type possesses distinct features that cater to specific applications. For instance, register rings are essential for maintaining dimensional accuracy in complex assemblies, while sprue inserts are designed to facilitate material flow during the injection moulding process. Innovations such as additive manufacturing offer new possibilities for creating intricate, thin-walled cavities, providing manufacturers with better control over precision. Recent studies highlight the use of metal epoxy composites (MEC) as a formidable alternative to traditional materials, showcasing enhanced thermal resistance and compressive strength.

Understanding the various types of mould inserts is crucial for enhancing manufacturing efficiency. Each mould insert type possesses distinct features that cater to specific applications. For instance, register rings are essential for maintaining dimensional accuracy in complex assemblies, while sprue inserts are designed to facilitate material flow during the injection moulding process. Innovations such as additive manufacturing offer new possibilities for creating intricate, thin-walled cavities, providing manufacturers with better control over precision. Recent studies highlight the use of metal epoxy composites (MEC) as a formidable alternative to traditional materials, showcasing enhanced thermal resistance and compressive strength.

Tip: When selecting a mould insert type, consider the specific requirements of your application, including thermal properties, dimensional tolerances, and manufacturing capabilities.

The evolving landscape of precision manufacturing is significantly influenced by advancements in 3D printing technologies, especially fiber-reinforced composites. This method enhances the strength and durability of components across various industries, including aerospace and automotive. A recent analysis indicates that the adoption of these innovative materials in mould insert fabrication not only optimizes production processes but also reduces waste, leading to more sustainable manufacturing practices.

Tip: Invest in training your design team on the latest material properties and production techniques to leverage the full potential of emerging technologies in mould insert development.

When it comes to enhancing manufacturing efficiency, the choice of mould insert types is crucial. Several factors influence this decision, including material compatibility, production volume, and product design. For instance, according to a recent report from the Association for Manufacturing Technology (AMT), the right mould insert can reduce cycle times by up to 30%, significantly impacting overall productivity. This is especially true in high-volume production settings where micro-optimizations can lead to substantial cost savings.

Another critical factor is the durability and wear resistance of the mould insert materials. According to a study by the Society of Plastics Engineers, moulds made from high-performance alloys and coatings can extend the lifespan of inserts by over 40%. This not only reduces the frequency of replacements but also assures consistency in product quality. Manufacturers must carefully consider these variables to ensure that the selected mould inserts align with both their operational goals and the specific demands of their product line.

When it comes to maximizing manufacturing efficiency, understanding the different types of mould inserts is crucial. A comparative analysis reveals that the cost-effectiveness and performance of mould inserts can vary significantly. According to a recent study by the International Plastics Association, mould inserts can account for up to 30% of the total tooling costs. However, selecting the appropriate insert material—such as steel, aluminum, or composite—can lead to cost reductions of up to 15% while also enhancing the lifespan of the tooling.

One of the key factors in improving cost-effectiveness is the insert's thermal conductivity. Mould inserts with higher thermal conductivity, like copper alloys, can reduce cycle times by up to 25%, which directly influences production output. Moreover, a report from the Engineering Plastics Innovation Council suggests that investing in advanced inserts may yield a ROI as high as 40% within the first year, given their impact on reducing scrap rates and downtime.

Tip: Consider using temperature-controlled mould inserts to further enhance performance and efficiency. These advanced systems allow for precise heat management, which can reduce warpage and improve part quality.

Tip: Regularly evaluate your insert choices in relation to your specific production needs. Utilizing benchmarking reports will help you make informed decisions and adapt to new materials or technologies that can enhance your manufacturing processes.

When it comes to manufacturing efficiency, selecting the right mould insert type is critical. According to a 2022 report by the Society of Manufacturing Engineers, businesses that optimize their mould insert selection can improve production efficiency by up to 25%. This statistic highlights the significant impact that appropriate mould insert choices can have on overall operational performance. Factors to consider include the material compatibility, cooling needs, and the specific geometry required for the part being produced.

Tip 1: Assess your production volume needs first; high-volume runs often benefit from hardened steel inserts, which offer durability and longevity, reducing replacement costs over time.

Moreover, it's essential to stay updated on the latest advancements in mould insert technology. A study conducted by the American Injection Molding Institute found that using modular inserts can cut setup time by 40%, leading to faster production cycles. Incorporating innovative materials such as P20 or S7 can also enhance performance, especially for intricate designs needing elevated precision.

Tip 2: Experiment with different coatings on your mould inserts to optimize wear resistance and surface finish, as this can significantly affect the quality of the final product.

By strategically selecting and utilizing the right mould inserts, manufacturers can ensure improved efficiency and superior product quality in their operations.