In 2026, Mould Die Design stands at the forefront of manufacturing innovation. As industries strive for efficiency, the role of precise die design becomes paramount. Effective mould dies streamline production, reduce waste, and enhance product quality. Designers face unique challenges when creating dies that meet evolving market demands.

Successful mould die design requires a blend of creativity and technical knowledge. Every detail matters, from the choice of materials to the shaping processes. A small oversight can lead to significant production delays. Manufacturers must continuously adapt and rethink their strategies to optimize designs for various applications.

However, effective design is not without its flaws. Often, what seems perfect on paper fails in real-world use. Designers need to reflect on past experiences, learning from mistakes to refine their approach. Embracing trial and error is essential in crafting mould dies that truly enhance manufacturing efficiency. As we look forward, the evolution of mould die design holds great potential for improving manufacturing outcomes across industries.

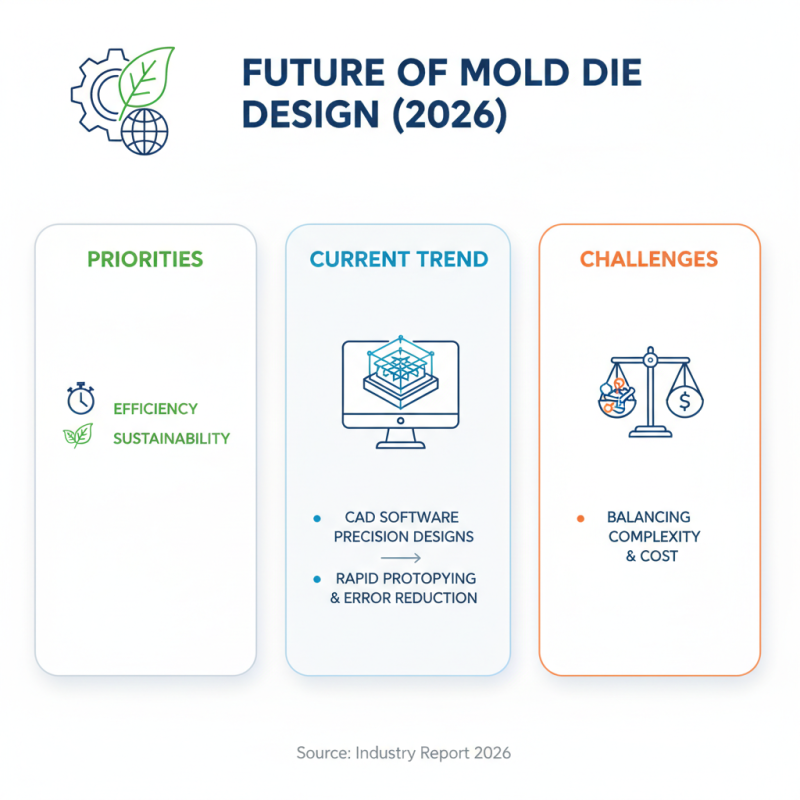

The landscape of mould die design is rapidly changing. In 2026, manufacturers need to prioritize efficiency and sustainability. One current trend is the use of CAD software for precision designs. This technology allows for rapid prototyping and reduces errors in the initial stages. However, challenges remain in balancing complexity and cost.

Another significant trend is the incorporation of advanced materials. Lightweight alloys and composites can enhance durability while lowering production costs. Yet, these materials often require more specialized knowledge. This creates a gap where many designers may struggle to adapt. The learning curve can be steep, and not all teams are equipped to handle it.

Lastly, automation plays a crucial role in mould die manufacturing. Robotics and AI streamline production processes. Yet, reliance on automation can lead to a loss of craftsmanship. Finding the right balance is essential. It’s not just about efficiency; it’s about maintaining quality and innovation.

In 2026, the landscape of mould die fabrication will shift significantly. New materials will play a crucial role. Advanced composites and lightweight alloys are gaining attention. They offer durability and reduce production costs. Innovations in 3D printing technology will also be vital. This method allows for intricate designs and rapid prototyping. Yet, challenges remain in achieving material consistency and reliability.

The integration of AI in the design process is another promising development. It helps optimize designs, reducing waste. However, AI-driven designs may miss certain nuances that experienced human designers can spot. Manufacturers must balance automation with human insights. The importance of sustainable materials cannot be overlooked. Eco-friendly options are becoming more popular but may not always meet performance criteria.

Investing in experimental techniques will also be necessary. Testing the durability and feasibility of new designs can be resource-intensive. Unexpected failures might occur, highlighting the need for careful assessment. Companies will need to cultivate a culture of innovation and reflection. Embracing imperfection can lead to breakthroughs. As we look ahead, the fusion of technology and creativity in mould die design will define the industry’s future.

This chart illustrates the projected percentage usage of various materials in mold die fabrication for efficient manufacturing in 2026. Steel remains the primary material, while innovative technologies like 3D printing are emerging, representing a small but significant part of the production landscape.

Designing mould dies demands a blend of ergonomic principles and automation. Ergonomics shapes how craftsmen interact with tools. A well-designed die reduces strain, allowing operators to work longer without fatigue. This principle should guide the initial design phases.

Automation provides consistency and efficiency. Machines can perform repetitive tasks with high precision. However, relying solely on automation has its drawbacks; a lack of human oversight can lead to errors. Designs must include easy access for maintenance. Operators should feel involved in the process.

Including flexible features in the design helps. Moulds should adapt to various tasks. This adaptability enhances productivity. Reflecting on previous designs is crucial. Consider what worked or failed. Learning from mistakes leads to improved solutions in future projects.

Designing mould dies with sustainability in mind is crucial in 2026. The focus should be on using eco-friendly materials and processes. Waste reduction is key. Adopting recyclable materials can help minimize environmental impact. Efficient designs also reduce energy consumption during production.

Tips for sustainable mould die design include using computer-aided design (CAD) software. This technology allows for virtual testing, reducing material waste. Consider integrating modular designs. They enable easy updates and repairs without starting from scratch. This approach conserves resources and cuts costs.

Collaboration with suppliers is vital. Partnering with suppliers who prioritize sustainability encourages shared responsibility. Still, challenges arise. Sometimes, sustainable options may increase initial costs. We need to question if upfront investment is worth long-term benefits. Keeping an open mind to new methods can lead to breakthroughs in die manufacturing. Continuously reflect on the balance between efficiency and sustainability. Embrace imperfections in processes; they can lead to innovative solutions.

The future of mould die design holds exciting possibilities for enhanced productivity in manufacturing. With the rise of smart technology, integrative systems are becoming essential. Advanced software can predict optimal designs. This minimizes material waste and speeds up production times. However, reliance on technology can lead to unforeseen issues. Overlooking the human element might result in poor communication during the design process.

Sustainability is another key innovation area. Eco-friendly materials are gaining traction. Designers are experimenting with bioplastics and composites. These materials can reduce the carbon footprint. Yet, they may not possess the durability required for certain applications. It is crucial to strike a balance in selecting materials that promote efficiency and sustainability.

As robotic automation progresses, the flexibility of mould die design will improve. Customization is more achievable, tailored to specific needs. Yet, pursuing perfection in automation can complicate simple processes. Simple dies might still be the most efficient for certain tasks. A thoughtful examination of the balance between automation and craftsmanship is necessary for optimal production efficiency.