Cold Punching is an innovative technique used extensively in manufacturing. According to industry expert Dr. Jane Smith, “Cold Punching transforms metal into precise shapes without heat.” This process is crucial for creating components in automotive and aerospace sectors. It allows manufacturers to achieve high precision with minimal waste.

The method involves forcing metal into a die at room temperature. This process retains the material's strength while yielding intricate designs. Cold Punching is especially valued for its efficiency. It reduces production times and energy consumption. However, it requires careful calibration to avoid defects.

In the quest for perfection, challenges remain. One common issue is the potential for material fatigue. As Dr. Smith points out, “Balancing speed and quality in Cold Punching is an ongoing challenge.” Each project demands careful planning and risk assessment. Thus, Cold Punching remains a fascinating area for exploration and innovation in engineering.

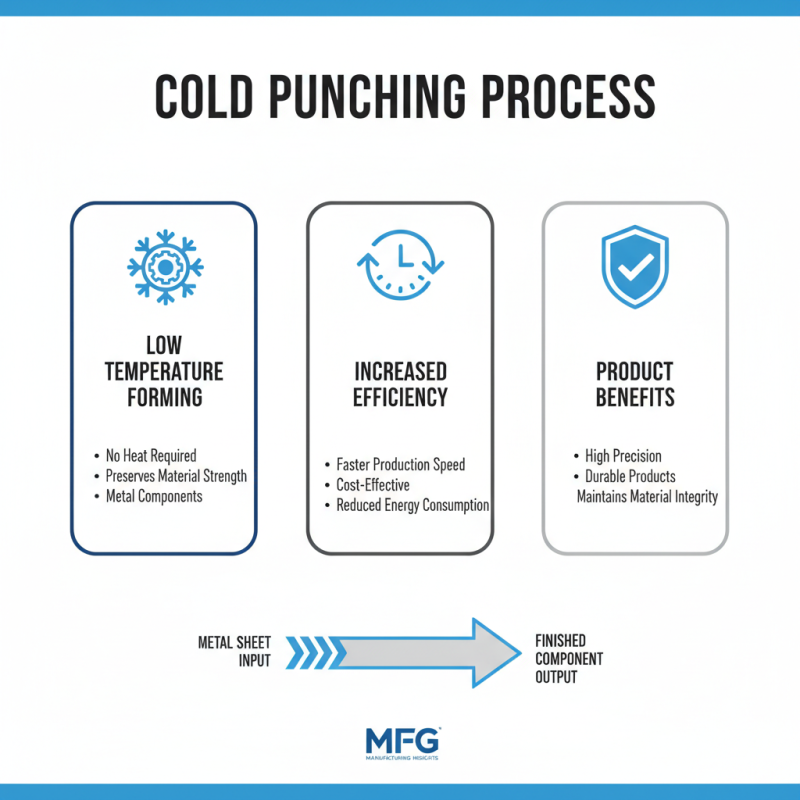

Cold punching is a manufacturing process that shapes materials at low temperatures. It typically involves forming metal components without the need for heat. This method preserves the metal's strength and integrity during the process. Cold punching is efficient and increases production speed. The result is often a highly precise and durable product.

When using cold punching, it's crucial to consider the material's properties. Not all metals respond well to cold forming. Testing is essential before proceeding with the final design. The process can sometimes lead to unintended defects. Keep an eye on the material's ductility and hardness.

**Tips:** Always use proper alignment during cold punching. Misalignment can cause uneven punches or damage to the tools. Regular maintenance of equipment is vital to ensure consistent results. Finally, consider experimenting with different materials. You may discover unexpected advantages or challenges that can enhance your production process.

Cold punching has a rich history that speaks to its evolution in manufacturing processes. Initially developed in the early 20th century, cold punching has transformed the way various materials are shaped and cut. According to a recent industry report, over 60% of manufacturers now prefer cold punching for its efficiency in producing precise components. This method, which uses high-pressure techniques to shape metals without heating, reflects advancements in technology and engineering.

The early days of cold punching relied heavily on manual labor. Workers used simple mechanical devices to execute punches. As technology advanced, automation entered the scene. Today, electric and hydraulic systems dominate the industry. A global market analysis highlighted a 14% annual growth rate for machinery involved in cold punching. Yet, challenges remain. For instance, material wastage can be significant if not managed properly. Many companies still grapple with optimizing their processes. This need for constant improvement is essential, as the competition grows in various sectors. Cold punching continues to evolve, showcasing both its benefits and the areas that require more focus.

| Dimension | Description |

|---|---|

| Process | Cold punching involves shaping metal by applying pressure without heating the material. |

| Materials Used | Commonly used materials include metals like steel, aluminum, and brass. |

| Applications | Used in automotive parts, electronics, construction components, and consumer goods. |

| History | Cold punching has evolved since the 19th century, becoming an essential manufacturing process in modern industry. |

| Advantages | High precision, low production costs, and minimal material waste are key benefits of cold punching. |

| Disadvantages | Limitations include lower ductility for certain materials and the necessity for precise tooling. |

| Future Developments | Innovations in technique and machinery aim to improve efficiency and expand material capabilities. |

Cold punching is an effective method used in metalworking. It involves the shaping of materials without heat. The process retains the material's strength. Let’s break down how it happens step by step.

Initially, a metal sheet is placed in a die. A punch then presses into the sheet. This action creates a shape defined by the die. The material can be transformed into various forms, such as brackets or rings. It’s important to control the pressure applied during this step. Too much pressure can damage the material. Conversely, insufficient pressure might result in incomplete shapes.

After the initial punching, the parts are often inspected. Sometimes, defects can be spotted that may have been overlooked. Operators need to refine their techniques continuously. Incomplete cuts or uneven surfaces can be quite common. Learning from these imperfections is crucial to improving the cold punching process. Consistent practice leads to better quality and efficiency over time.

Cold punching is a manufacturing process that reshapes materials without heating. This method has found numerous applications across various industries. It is particularly effective in the automotive sector, where precision and strength are critical. According to recent industry reports, automotive components made through cold punching demonstrate improved durability compared to parts created using traditional methods.

In the electronics industry, cold punching is employed to produce small, intricate components. The process allows for high accuracy while minimizing material waste. Recent studies indicate that using cold punching can reduce production costs by up to 25% in electronics manufacturing. However, this method also presents challenges, especially regarding tool wear. The precision required means that tools can wear out quickly, leading to potential production delays.

The aerospace sector also benefits from cold punching technology. Manufacturers use it to create lightweight yet strong components. Reports show that this method can help reduce the weight of aircraft parts by up to 15%. Yet, the reliance on cold punching requires continuous innovation to keep up with material advancements. Some manufacturers struggle to adapt quickly enough, leading to inefficiencies.

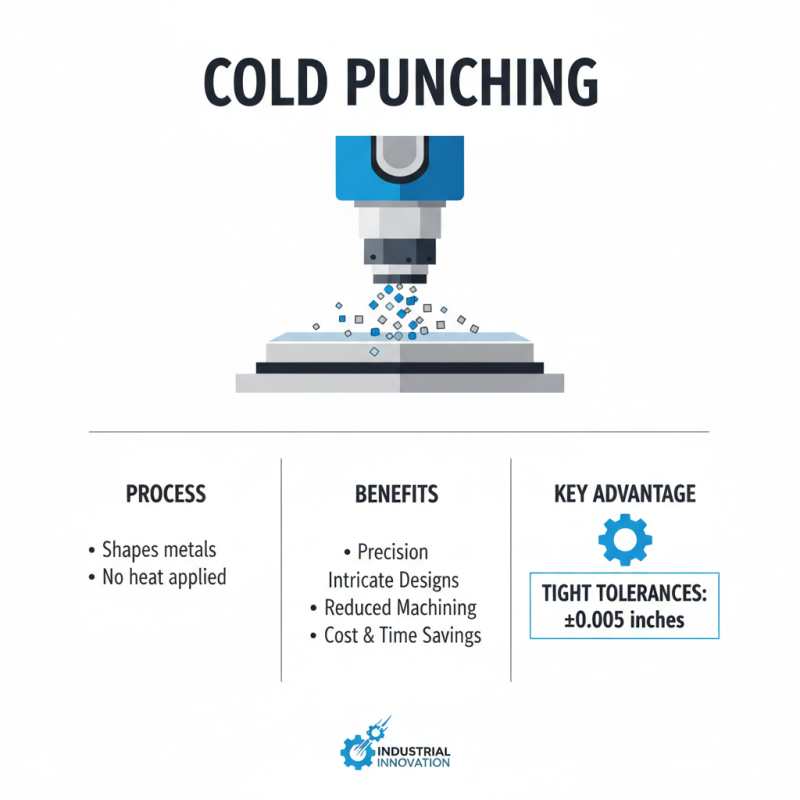

Cold punching is a process used to shape and form materials, primarily metals, without heating them. This technique offers various advantages. One notable benefit is its ability to produce intricate designs with high precision. Studies show that cold punching can achieve tolerances as tight as ±0.005 inches. This accuracy reduces the need for further machining, saving time and costs.

However, cold punching also has limitations. The process can induce stress within the material, potentially leading to cracking or deformation. Statistical data indicates that 5-10% of materials may be compromised due to this issue. The thickness of the material also affects the feasibility of cold punching. Thinner sheets generally provide better results, while thicker sheets may be challenging to work with. Consequently, manufacturers must weigh these factors when deciding on cold punching as their shaping method.