In the rapidly evolving landscape of modern manufacturing, the importance of CNC (Computer Numerical Control) experience cannot be overstated. As industries increasingly adopt advanced technologies to enhance efficiency and precision, the demand for skilled professionals with CNC expertise continues to rise. According to a report by the National Association of Manufacturers (NAM), approximately 2.4 million manufacturing positions are expected to remain unfilled by 2028 due to a skills gap, highlighting the critical need for workforce development in fields requiring CNC capabilities.

CNC experience not only equips workers with the necessary technical skills to operate sophisticated machinery, but it also fosters a deeper understanding of manufacturing processes and product design. A study from the American Society of Mechanical Engineers (ASME) indicates that companies that prioritize training in CNC technology see a 20% increase in productivity and a significant reduction in operational costs. This statistic underscores the transformative power of CNC experience, as it not only enhances individual career prospects but also drives competitive advantage for organizations in the industry.

As manufacturing continues to advance toward automation and smart technologies, the integration of CNC systems becomes integral to maintaining relevance in the market. The future of manufacturing will heavily rely on the expertise of workers who can leverage CNC experience to innovate and adapt, solidifying its necessity in achieving success within modern manufacturing environments.

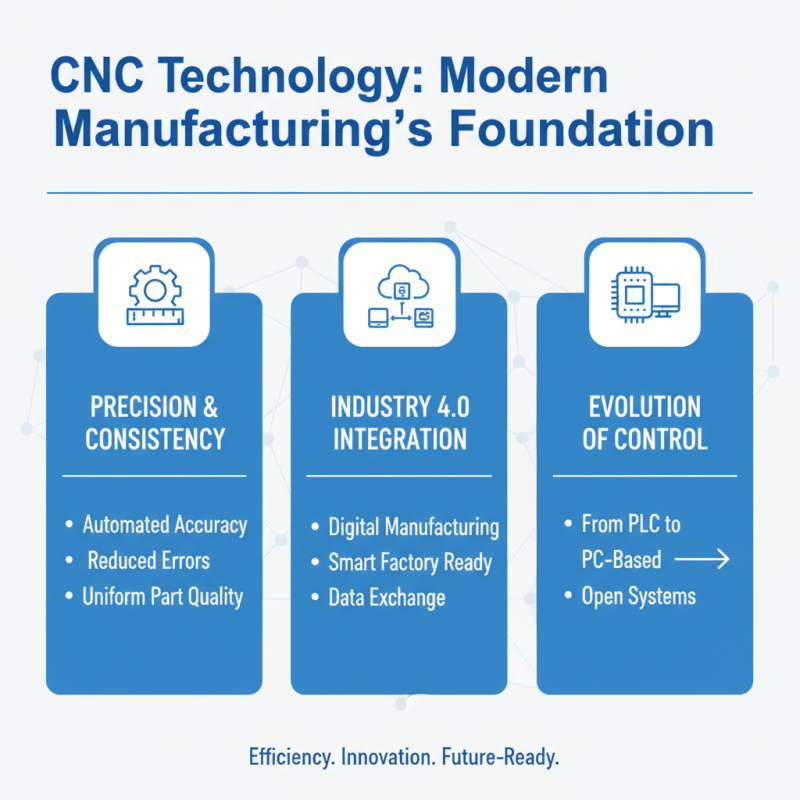

CNC (Computer Numerical Control) technology is a cornerstone of modern manufacturing, facilitating precision, consistency, and efficiency in machining processes. As industries continue to evolve towards Industry 4.0, CNC systems are becoming increasingly vital. The transition from traditional PLC-based controllers to more open, PC-based systems reflects a significant shift in the capabilities of CNC technology, enabling greater integration with digital manufacturing solutions.

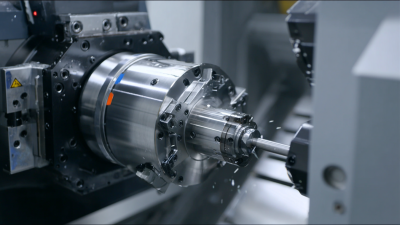

To thrive in today's competitive landscape, manufacturers must embrace CNC experience. This skillset not only enhances productivity but also allows for the implementation of advanced automation technologies. CNC machines, such as 2D and 3D milling machines, offer unprecedented accuracy in cutting and sculpting materials, positioning companies to meet the growing demand for high-quality outputs.

**Tips:** Focus on acquiring hands-on experience with CNC systems to understand their operational intricacies. Additionally, familiarize yourself with industry trends and advancements in CNC technology, as this knowledge is essential for making informed decisions in modern manufacturing. Networking with industry professionals can also provide valuable insights and opportunities for collaboration.

In modern manufacturing processes, Computer Numerical Control (CNC) technology plays a pivotal role in enhancing productivity and precision. As industries strive for higher efficiency and quality, the integration of CNC machines has become indispensable. These machines allow for automated control of machining tools, significantly reducing human error and time required for manual operations. By adopting CNC technology, manufacturers can achieve consistent outputs with exceptional accuracy, meeting the increasing demand for high-precision components across various sectors.

Furthermore, the shift towards CNC-driven solutions aligns with the industry's movement towards sustainable practices. Many CNC machines are designed to minimize waste and optimize resource use, making them eco-friendly alternatives to traditional manufacturing methods. This is particularly crucial as businesses seek to comply with environmental regulations while maintaining competitiveness. As a result, companies that harness CNC technology not only improve their operational efficiency but also contribute positively to environmental sustainability, positioning themselves favorably in the modern manufacturing landscape.

In today's rapidly evolving manufacturing landscape, CNC (Computer Numerical Control) experience is increasingly becoming a cornerstone for workforce development. Understanding CNC technology equips workers with the skills to operate advanced machinery that enhances precision and efficiency. This technical knowledge allows employees to interpret complex blueprints and understand programming nuances, leading to higher quality products and reduced error rates. By fostering CNC proficiency, companies can create a more capable workforce that meets industry demands.

Furthermore, CNC experience serves as a catalyst for career advancement within the manufacturing sector. Employees with CNC skills are often more sought after, as they possess the ability to execute intricate tasks that traditional machining techniques cannot achieve. As industries move towards automation and smart manufacturing, workers equipped with CNC knowledge can position themselves for leadership roles, driving innovation and improving operational efficiencies. Investing in CNC training not only benefits individual workers but also strengthens the overall competitiveness of the manufacturing industry.

In the realm of modern manufacturing, CNC (Computer Numerical Control) skills play a pivotal role in enhancing productivity and efficiency. The ability to operate CNC machines allows manufacturers to streamline their production processes, minimize human error, and produce high-quality products consistently. With CNC technology, operators can execute intricate designs and tap into advanced features that traditional methods cannot match. This technological advantage not only speeds up production timelines but also significantly reduces material waste, thereby contributing to cost savings.

Moreover, possessing CNC expertise empowers employees to adapt to the ever-evolving manufacturing landscape. As industries increasingly embrace automation and precision engineering, those with solid CNC skills can effectively optimize machine operations and troubleshoot issues in real time. This adaptability not only fosters a culture of continuous improvement within organizations but also enhances overall workflow. Consequently, the development of CNC proficiency among workers emerges as a crucial factor for businesses aiming to stay competitive in a fast-paced market.

This chart illustrates the correlation between the level of CNC skills and productivity metrics in modern manufacturing environments. Higher CNC proficiency leads to significant improvements in efficiency and output.

The importance of CNC experience in modern manufacturing cannot be overstated, particularly as we look to future trends in the industry. As digitalization transforms traditional manufacturing, markets are projected to see significant growth. For instance, the global CNC video measurement market was valued at $92.11 million in 2022, and it's expected to expand at a compound annual growth rate (CAGR) of 6.9%, reaching approximately $157.11 million by 2030. This growth underscores the necessity for manufacturers to embrace CNC technologies to stay competitive.

Moreover, the CNC machining center market is also poised for impressive expansion. By 2025, the market size is estimated at $14.35 billion, with projections to rise to $21.69 billion by 2033, reflecting a CAGR of 5.7%. Such trends highlight a clear shift towards automation and precision in manufacturing processes, driven by the increasing demand for customized solutions. In addition, the overall metal processing machinery market is anticipated to reach $103.87 billion by 2035, growing at an average annual rate of 3.08%. These figures illustrate the essential role of CNC experience as manufacturers adapt to the evolving landscape of smart manufacturing and industrial internet of things.