In the realm of precision metalworking, the choice of HSS punches can significantly impact the overall quality and efficiency of projects. High-speed steel (HSS) punches are renowned for their durability and precision, making them essential tools in various industrial applications. According to a market analysis by Grand View Research, the global metalworking tools market is projected to reach $75 billion by 2025, driven by the increasing demand for precision manufacturing and advanced tooling solutions. This underscores the importance of selecting the right tools, such as HSS punches, to maintain competitive advantage.

Expert insights emphasize the critical role HSS punches play in achieving precise outcomes. John Smith, a leading expert in metalworking tools, states, “The right HSS punch can make all the difference in achieving accuracy and efficiency. It’s imperative for metalworkers to invest in high-quality punches for optimal results.” His perspective highlights that not only the size and shape of the HSS punches are important but also their material properties, which directly correlate with the performance in high-stress environments. Therefore, understanding the specific requirements of different projects is vital when selecting these essential tools.

When it comes to precision metalworking projects, choosing high-speed steel (HSS) punches can significantly impact the quality and efficiency of your work. HSS punches are designed for creating holes in various materials, offering exceptional durability and sharpness. Key features to consider include the punch's hardness, which is typically rated on the Rockwell scale, and its geometry, which enables clean cutting edges that minimize burr formation. Additionally, the versatility of HSS punches makes them suitable for a wide range of applications, from sheet metal fabrication to intricate pattern work.

Tips for selecting the best HSS punches include examining the punch size and compatibility with your specific project requirements. For projects that demand high precision, opt for punches with finer tolerances. It’s also advisable to select punches that are easy to sharpen and maintain, as this will extend their lifespan and ensure consistent performance. Pay attention to the cutting angles; a well-designed angle can enhance the efficiency of the punching process.

Moreover, understanding the benefits of HSS punches can help streamline your workflow. These punches often offer superior resistance to wear compared to their carbon steel counterparts, making them ideal for high-volume production. They maintain their sharpness longer, which reduces downtime for tooling replacements. Ultimately, by investing in quality HSS punches, you ensure a higher standard of quality in your metalworking projects, leading to better results and greater satisfaction.

| Feature | Benefits | Recommended Usage | Material Compatibility |

|---|---|---|---|

| Material Quality | Durable and long-lasting, withstands repetitive use | Heavy-duty tasks, frequent punching | Steel, aluminum |

| Precision | Provides accurate and clean cuts | Fine detailing work, intricate designs | Copper, brass |

| Ease of Use | Simple handling, reduces operator fatigue | Long working sessions, high-volume production | Sheet metal |

| Variety of Sizes | Versatile for multiple project requirements | Different hole sizes needed | Various metals |

| Heat Resistance | Maintains performance under high temperatures | Heavy machining with high friction | Thermal-sensitive metals |

When selecting HSS (high-speed steel) punches for precision metalworking projects, assessing material compatibility is crucial. Different metals have varying properties that affect the punching process, including hardness, tensile strength, and ductility. For example, softer materials like aluminum are easier to punch through, requiring less force and thus allowing for faster production rates. Conversely, harder metals such as stainless steel require high-quality HSS punches with specific coatings or treatments to enhance durability and maintain sharpness throughout the operation.

Additionally, the thickness of the material plays a significant role in determining the appropriate HSS punch. Thicker metals necessitate punches with a robust design to withstand the increased pressure. It is also essential to consider the type of finish required on the punched holes, as some materials may burr easily while others can produce cleaner results. Matching the HSS punches to the specific characteristics of the metals involved in your projects can significantly improve both efficiency and finishing quality, ensuring that the metalworking tasks are completed accurately and effectively.

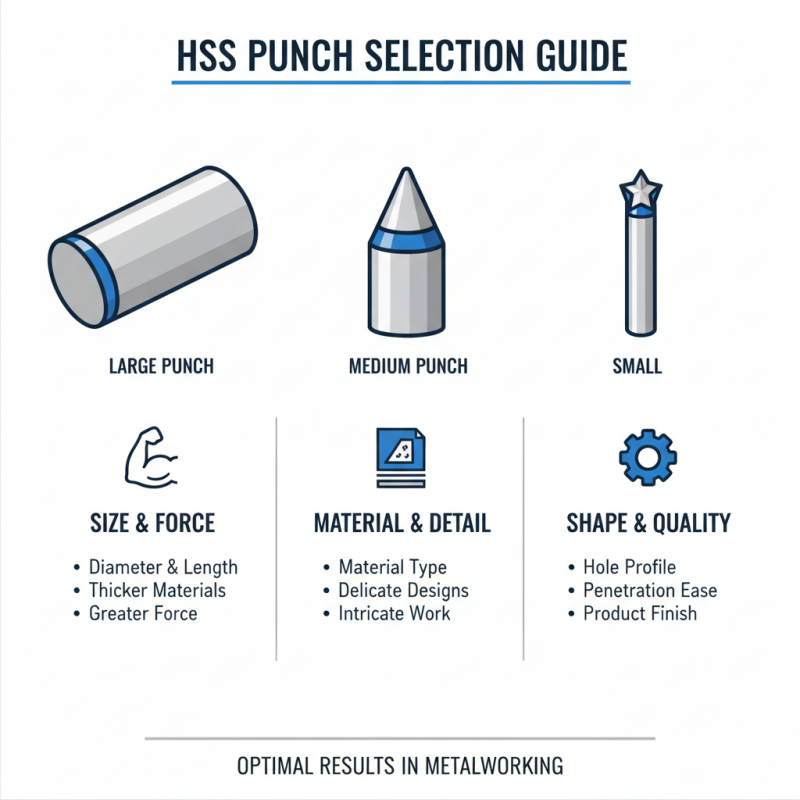

When selecting HSS punches for precision metalworking projects, the size and shape of the punches play a critical role in achieving optimal results. The diameter and length of the punch must be suited to the thickness and type of material being worked on. For instance, larger punch sizes can lead to greater force application, making them ideal for thicker materials, while smaller punches are perfect for delicate or intricate designs. The shape of the punch not only affects the hole's profile but also the ease of penetration into the workpiece, influencing the quality of the final product.

Tips: Always consider the material properties of the workpiece when choosing punch shapes. For example, tapered punches can reduce resistance and provide cleaner cuts in softer metals. In contrast, flat-ended punches might be better suited for harder materials where precision is crucial. Additionally, ensuring that your punch is well-maintained will enhance its longevity and maintain its precision, thus improving the accuracy of your metalworking projects.

Moreover, analyzing the punch geometry is essential. Different shapes such as round, hexagonal, or square can impact the performance and fit of the resultant holes. For specific applications, such as fitting bolts or screws, selecting the correct punch shape ensures that components align properly and function efficiently. Always keep in mind that the right punch choice can significantly enhance both the precision of your work and the performance of your overall metalworking processes.

Maintaining HSS punches effectively is essential for ensuring their longevity and optimal performance in precision metalworking projects. Regular maintenance not only enhances the efficiency of the punches but also reduces the likelihood of costly replacements. One key tip is to clean the punches after each use to remove any metals or debris that may cause wear over time. Using a soft cloth and appropriate solvents can help maintain their sharpness and prevent corrosion.

Another important maintenance practice is to inspect the punches regularly for any signs of dullness or damage. Checking for chips, cracks, or excessive wear can help identify when it's time to sharpen or replace the tool. Keeping a dedicated sharpening tool or service on hand can prevent interruptions in your project workflow and ensure that your punches are always in peak condition.

Lastly, storing HSS punches correctly is crucial. Using a protective case or rack to keep them organized and free from impact will safeguard their edges and overall integrity. Avoiding exposure to moisture by storing them in a dry environment can significantly enhance their lifespan. By implementing these maintenance tips, you can ensure that your HSS punches remain efficient and durable for your metalworking needs.

This chart illustrates key performance metrics for HSS punches used in precision metalworking. It displays the average usage frequency, maintenance checks, lifespan, and efficiency rating, providing insights into how these factors influence the effectiveness and durability of HSS punches.

When selecting high-speed steel (HSS) punches for precision metalworking projects, adhering to industry standards and certifications is crucial for ensuring product quality. HSS punches should conform to recognized specifications, such as those set by the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). These certifications validate not only the material composition but also the manufacturing processes employed, ensuring that the punches are capable of delivering consistent performance in demanding applications.

Moreover, understanding the specific certifications related to hardness, tensile strength, and wear resistance can further guide your choices. For instance, punches meeting specific hardness criteria, often indicated in Rockwell hardness ratings, are more likely to provide durability and longevity. Quality certifications also often imply that the manufacturer has implemented rigorous quality control measures throughout the production process. This focus on quality assurance helps minimize defects and ensures that the punches perform well, even under high-stress conditions. By prioritizing tools that meet these industry standards, you can enhance the reliability and precision of your metalworking projects.