When it comes to precision metal cutting, selecting the right equipment is crucial for achieving optimal results. The Small Wire EDM (Electrical Discharge Machining) has become an essential tool for manufacturers looking for high precision and intricate designs. Industry expert Dr. Steven Ross, a leading figure in precision engineering, emphasizes this by stating, “The right Small Wire EDM can significantly enhance productivity and precision in complex metal fabrication tasks.”

As the demand for more sophisticated metal components rises, understanding the nuances of Small Wire EDM technology is vital. This specialized machining process allows for intricate cutting that traditional methods cannot achieve, providing manufacturers the ability to produce highly detailed and accurate parts. By carefully assessing factors such as wire diameter, feed rate, and machine capabilities, operators can find the ideal Small Wire EDM that aligns with their production needs, ensuring efficiency and top-quality results.

In the upcoming sections, we will delve into the critical aspects of choosing the right Small Wire EDM, guiding you through essential considerations that will help streamline your manufacturing processes while enhancing precision in your projects. Whether a seasoned professional or new to the field, understanding these elements will enable you to make informed decisions in your procurement process.

Small Wire Electrical Discharge Machining (EDM) technology has gained significant traction in the manufacturing sector, particularly for precision metal cutting applications. Unlike traditional machining methods, small wire EDM utilizes a thin, electrically charged wire to shape metals with high accuracy and minimal material waste. According to a report by MarketsandMarkets, the global EDM market is expected to reach $8.9 billion by 2025, reflecting a growing demand for advanced manufacturing techniques that enhance precision.

One of the key advantages of small wire EDM is its ability to produce complex geometries that are often challenging to achieve with conventional methods. The process employs controlled erosion, allowing for intricate designs without the need for extensive tooling. This makes it ideal for industries ranging from aerospace to medical device manufacturing, where precision is critical. Research indicates that small wire EDM can achieve tolerances as tight as 5 microns, facilitating the creation of highly detailed components.

**Tips:** When selecting a small wire EDM machine, consider the machine's wire diameter capabilities and the maximum workpiece thickness it can handle. Additionally, assess the speed and efficiency of the wire feed system to ensure optimal performance in your specific applications. Regular maintenance and the use of high-quality consumables can significantly improve machining accuracy and prolong the lifespan of your equipment.

When selecting the right small wire EDM (Electrical Discharge Machining) machine for precision metal cutting, several key factors need to be considered to ensure optimal performance and efficiency. First and foremost, the machine's capability in handling various materials is critical. Different metals have distinct properties that affect the cutting process, so it’s essential to choose a machine that can accommodate the specific materials you’ll be working with, whether they are steel, aluminum, or other alloys.

Another important factor is the machine's accuracy and repeatability. Precision is paramount in EDM processes, and a machine that offers high-resolution cutting capabilities will produce better results. Therefore, it's advisable to review specifications such as the machine's cut speed, surface finish quality, and tolerance levels. Additionally, consider the user-friendliness of the machine’s control interface and software, as a more intuitive system will enhance productivity and reduce the learning curve for operators. These factors collectively contribute to the overall performance of the wire EDM machine and should be carefully weighed during the selection process.

| Factor | Description | Importance Level | Recommended Specs |

|---|---|---|---|

| Cutting Speed | The rate at which the EDM machine can cut through metal. | High | > 200 mm/h |

| Wire Diameter | The thickness of the wire used in the EDM process. | Medium | 0.25 - 0.3 mm |

| Accuracy | The degree to which the EDM machine can produce precise cuts. | High | ± 0.001 mm |

| Workpiece Size | The maximum dimensions of the materials that can be processed. | High | 500 x 400 mm |

| Software Control | The technology used to program and control the EDM process. | Medium | User-friendly interface, CAD compatibility |

| Power Consumption | The amount of electrical power required to operate the machine. | Medium | < 5 kW |

| Maintenance Requirements | The frequency and type of maintenance required for the machine. | High | Regular checks every month |

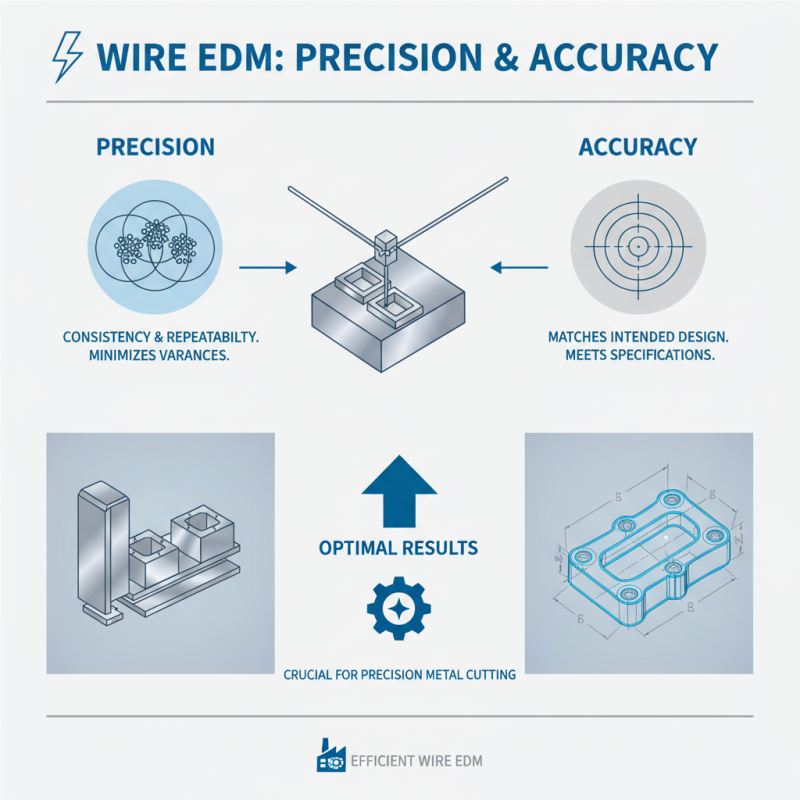

When it comes to wire EDM (Electrical Discharge Machining), precision and accuracy are paramount. Evaluating these two factors is crucial for achieving optimal results in precision metal cutting. Precision refers to the capability of the machine to reproduce the same dimensions and tolerances consistently, while accuracy denotes how closely the machined part matches the intended design. An efficient wire EDM should deliver high precision by minimizing variances during the cutting process, ensuring that the finished parts meet stringent specifications.

To assess the precision and accuracy of a wire EDM machine, several criteria must be considered. Firstly, the wire tension and alignment must be meticulously maintained, as improper tension can lead to deviations in cut dimensions. Additionally, the machine's control systems should exhibit advanced capabilities, such as adaptive control functions that compensate for variations in material properties or environmental conditions. The use of high-quality wire materials and optimal cutting parameters can also significantly enhance the overall precision and accuracy of the machining process. By focusing on these aspects, manufacturers can select a wire EDM machine that effectively meets their precision and accuracy needs for cutting complex metal shapes.

When considering the purchase of a small wire EDM (Electrical Discharge Machining) system, cost is a pivotal factor that can influence your decision. The initial price of the machine is just the starting point; it’s essential to take into account additional expenses such as maintenance, consumables, and the potential costs of downtime. While some models may appear more affordable upfront, they may require more frequent maintenance or spare parts that can drive up total ownership costs over time.

In addition to the direct costs associated with the EDM machine itself, budget considerations should also include the expected return on investment (ROI). This involves evaluating the potential efficiency gains in your metal cutting processes and how quickly the machine can pay for itself through improved productivity. It’s wise to analyze specific project requirements and workflow scenarios to establish which EDM options can fit your budget while still meeting your precision and volume needs. By carefully assessing both the initial investment and the long-term financial impacts, you can select an EDM solution that aligns with your operational objectives and financial constraints.

Maintaining small wire EDM (Electrical Discharge Machining) machines is crucial for ensuring their long-term performance and precision in metal cutting applications. Regular maintenance not only helps to extend the lifespan of the equipment but also enhances the accuracy and consistency of the cutting process.

According to a report by the International Society of Automation, routine maintenance can reduce unexpected machine downtime by up to 30%, significantly improving operational efficiency for manufacturers. This figure highlights the importance of establishing a scheduled maintenance regimen, which includes regular checks on wire tension, coolant condition, and electrical components.

Support systems play a vital role in the longevity of wire EDM machinery. An effective support structure typically includes access to technical assistance and readily available spare parts. A survey from the Precision Metalforming Association indicates that companies with strong manufacturer support experience 15% lower operational costs than those without. This support proves invaluable when addressing complex issues that may arise during production. Proper troubleshooting and timely repairs can ensure that machines remain calibrated, allowing users to maintain tight tolerances and high-quality standards in metal cutting applications, which is essential in competitive industries.