Metal fabrication is an essential component across various industries, driving innovation and efficiency in production processes. According to a report by IBISWorld, the metal fabrication industry is expected to reach $134 billion by 2025, reflecting a compound annual growth rate of 3.4%. This significant growth underscores the increasing reliance on metal fabrication techniques to meet diverse project needs, ranging from construction and automotive to aerospace and electronics.

Metal fabrication is an essential component across various industries, driving innovation and efficiency in production processes. According to a report by IBISWorld, the metal fabrication industry is expected to reach $134 billion by 2025, reflecting a compound annual growth rate of 3.4%. This significant growth underscores the increasing reliance on metal fabrication techniques to meet diverse project needs, ranging from construction and automotive to aerospace and electronics.

Choosing the right metal fabrication technique is crucial for optimizing performance, cost, and durability. Various methods—such as welding, machining, and laser cutting—offer unique benefits and applications tailored to specific requirements. This blog will explore the advantages of different metal fabrication techniques, helping you make informed decisions for your projects and ensuring they are completed efficiently and effectively.

When embarking on a metal fabrication project, understanding your project requirements is pivotal. The first step is to clearly define the purpose of the fabricated metal piece. Consider factors such as size, shape, and the type of material that will be used.

Different metals have unique properties that affect their suitability for various applications. For instance, aluminum is lightweight and corrosion-resistant, making it ideal for projects where weight is a concern. In contrast, steel is often selected for its strength and durability, especially in structural applications.

Another critical aspect of your project requirements is the intended environment for the fabricated product. If the application involves exposure to harsh conditions, like moisture or extreme temperatures, selecting the right metal and coating process can enhance longevity and performance. Additionally, consider the estimated production volume. High-volume projects might benefit from automated processes like CNC machining, whereas custom, low-volume designs may be better suited for manual techniques. By thoroughly evaluating these factors, you can ensure the chosen fabrication methods align effectively with your project needs, leading to successful and efficient outcomes.

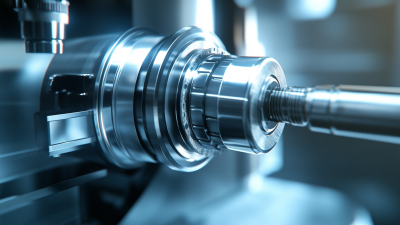

When selecting metal fabrication techniques for a project, it's essential to understand the different methods available and their specific applications. Common techniques like welding, machining, and bending offer unique advantages depending on the material and design requirements. For instance, welding is ideal for creating strong joints in structural components, while machining allows for high precision in creating intricate parts. Bending, on the other hand, is often employed for shaping sheets into desired forms without compromising the integrity of the metal.

When selecting metal fabrication techniques for a project, it's essential to understand the different methods available and their specific applications. Common techniques like welding, machining, and bending offer unique advantages depending on the material and design requirements. For instance, welding is ideal for creating strong joints in structural components, while machining allows for high precision in creating intricate parts. Bending, on the other hand, is often employed for shaping sheets into desired forms without compromising the integrity of the metal.

Additionally, emerging technologies such as laser cutting and 3D printing are revolutionizing the field of metal fabrication. Laser cutting provides exceptional accuracy and clean edges for complex designs, making it perfect for projects requiring a high level of detail. Conversely, 3D printing enables the rapid prototyping of metal parts, allowing for innovative designs that were previously impossible with traditional methods. Each technique serves distinct purposes, and understanding them can lead to more effective project outcomes, ensuring the right match for your specific needs.

When selecting the appropriate metal fabrication technique for your project, several critical factors come into play. Firstly, consider the material type and thickness you are working with. Different techniques, such as welding, machining, or bending, may be more effective depending on the specific metal properties. For instance, aluminum often requires different handling techniques compared to stainless steel, affecting durability, weight, and cost. Understanding material specifications can help streamline the fabrication process and ensure optimal results.

Another essential factor is the complexity of the design. If your project involves intricate shapes or tight tolerances, techniques like laser cutting or CNC machining may be more suitable. These methods offer precision and can accommodate complex geometries that traditional fabrication techniques may struggle with. Additionally, evaluate your project timeline and budget, as some methods may involve longer lead times or higher costs but could yield superior quality. Balancing these considerations will help you choose the right fabrication method that aligns with your project's unique requirements.

When selecting the appropriate metal fabrication techniques for your project, cost-effectiveness and time efficiency are paramount. A recent report from Grand View Research indicates that the global metal fabrication market is expected to reach $19.95 billion by 2025, driven by the urgent need for cost-efficient solutions. Techniques such as laser cutting and CNC machining can significantly reduce wastage and labor costs, making them appealing options for many manufacturers. For instance, laser cutting can be up to 20% more efficient in terms of material usage compared to traditional cutting methods, thus lowering the overall project expenditure.

Additionally, time efficiency plays a critical role in manufacturing timelines. According to a study conducted by the Fabricators & Manufacturers Association, organizations that implement automated metal fabrication processes can achieve a 30% reduction in fabrication time. Techniques like 3D printing and robotic welding not only enhance production speed but also maintain high precision, reducing the likelihood of errors that can lead to costly delays. Therefore, when evaluating metal fabrication techniques, it is essential to consider both cost and time factors to ensure optimal project outcomes.

When embarking on a metal fabrication project, selecting the right materials is crucial to ensure durability and functionality. According to the 2023 Global Metal Fabrication Market Report, the demand for fabricated metal products is expected to grow at a CAGR of 5.5% over the next five years, driven largely by advancements in manufacturing technology and the rise of the automotive sector. Understanding the specific requirements of your project—whether that's strength, weight, corrosion resistance, or heat tolerance—can greatly influence the materials you choose.

For example, aluminum is often favored for its lightweight and corrosion-resistant properties, making it an ideal choice for aerospace applications. In contrast, steel remains a dominant material in construction and manufacturing due to its superior strength and affordability, as noted in the Steel Institute's Annual Review. Similarly, advanced materials such as titanium are gaining popularity for high-performance applications despite their higher costs, thanks to their unmatched strength-to-weight ratio and resistance to extreme temperatures. By thoroughly evaluating the characteristics and costs associated with each material, you can make more informed decisions that align with your project’s unique fabrication needs.

This chart illustrates the percentage usage of various materials in metal fabrication projects. Steel remains the most commonly used material, followed by aluminum and copper, illustrating the importance of selecting the right material for different project needs.