In recent years, the global manufacturing landscape has witnessed a significant shift, particularly in the context of the ongoing tariff challenges between the United States and China. Despite these hurdles, Chinese manufacturing has not only endured but has also thrived, showcasing remarkable resilience and adaptability. At the heart of this success is the innovative application of Mold Stamping solutions, which have enabled manufacturers to enhance efficiency and maintain competitive pricing. As companies seek to optimize their production processes while navigating the complexities of tariffs, the strategic implementation of Mold Stamping techniques emerges as a cornerstone for driving growth and achieving sustainability. This blog delves into how Chinese manufacturers continue to leverage advanced Mold Stamping technologies, enabling them to rise against economic pressures while delivering exceptional value in a challenging marketplace.

Chinese manufacturing is demonstrating remarkable resilience amidst the ongoing challenges posed by U.S. tariffs. Recent data from April highlights a significant 9.3% surge in exports, amounting to 2.27 trillion yuan ($314.17 billion), far exceeding expectations and underscoring the sector's robustness. Despite facing tariff pressures, which have led to a notable decline in exports to the U.S., the overall industrial output has shown commendable growth of 6.1%, a testament to the adaptability of Chinese manufacturers.

The strength of China's manufacturing sector is further exemplified by an increase in industrial profits and a recovery in factory activity, showcasing the industry's capacity to navigate economic hurdles. As companies implement best mold stamping solutions and continue to innovate, they are not only mitigating the impacts of tariffs but also repositioning themselves in the global supply chain. This dynamic landscape suggests that Chinese manufacturing, driven by strategic resilience and adaptability, can continue to thrive even in the face of adversity.

Amidst the challenges posed by tariffs, Chinese manufacturing is showcasing its resilience, notably through the adoption of innovative mold stamping solutions. These advancements not only enhance productivity but also reduce costs, enabling manufacturers to maintain competitiveness in an ever-evolving global market. According to a recent report by MarketsandMarkets, the global mold manufacturing market is projected to reach $41.3 billion by 2025, with mold stamping at the forefront owing to its efficiency and precision.

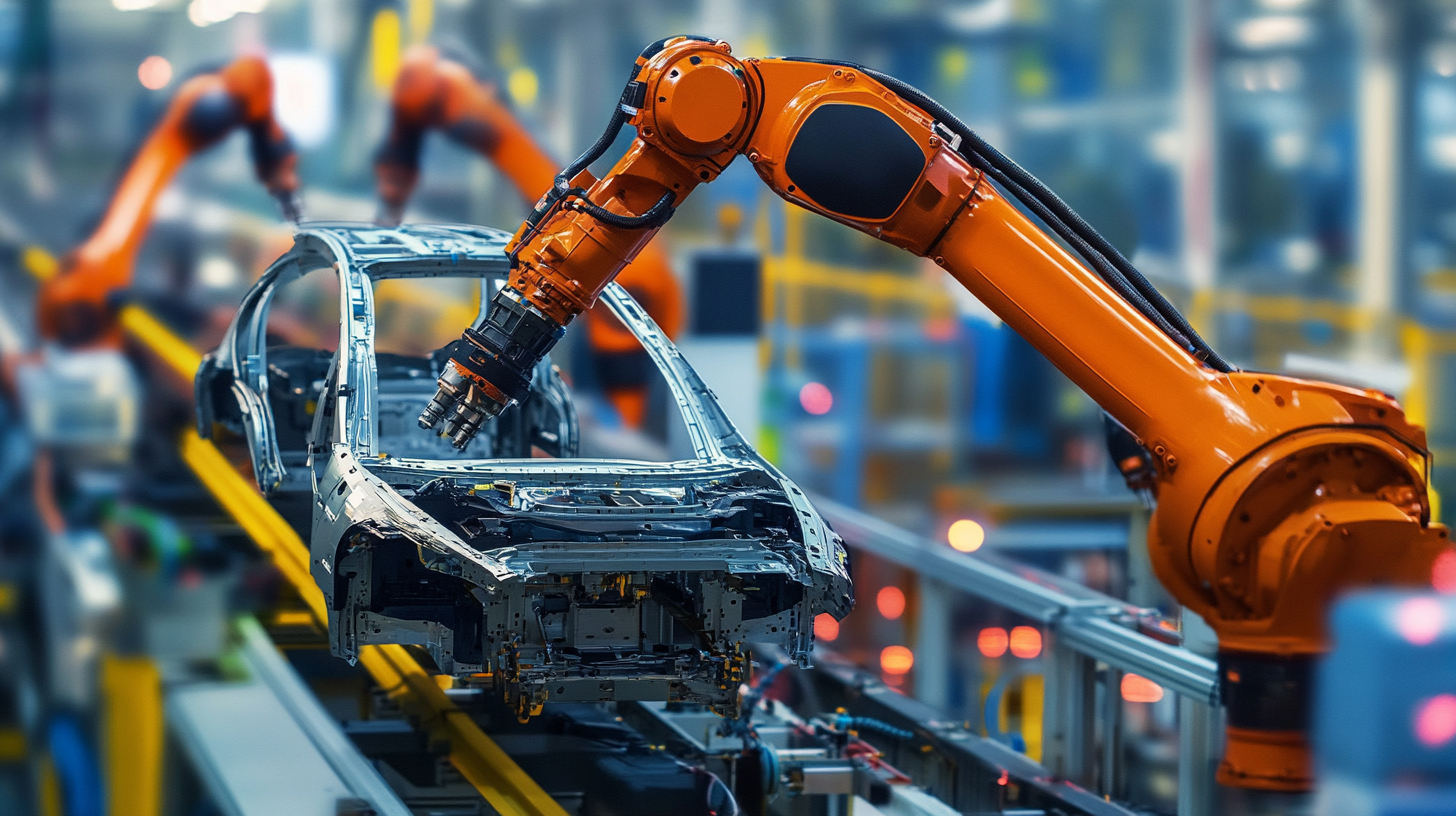

For manufacturers looking to gain a competitive edge, investing in state-of-the-art mold stamping technology can prove invaluable. Efficient mold design optimizes material usage, reduces waste, and shortens production cycles. A tip for manufacturers is to explore automation within the stamping process, as integrating robotics can lead to a significant increase in throughput and precision while minimizing human error.

Additionally, it's crucial to stay updated with industry trends and consumer demands. Engaging in continuous training for staff and adopting new materials can lead to innovative solutions that appeal to a broader customer base. By prioritizing these strategies, manufacturers can ensure that their mold stamping solutions not only meet current demands but also set the stage for future growth in a competitive landscape.

In the face of escalating tariff challenges, Chinese manufacturing has showcased its resilience and adaptability. Companies specializing in mold stamping solutions have leveraged their deep industrial capabilities and innovative technologies to not only survive but thrive. By refocusing their economic strategies, these manufacturers have successfully navigated the complexities of trade barriers, ensuring their competitive edge in the global market.

One key strategy entails investing in automation and advanced manufacturing techniques. This not only enhances productivity but also reduces dependency on labor, which is crucial when facing fluctuating labor costs and tariff implications. Additionally, companies are increasingly diversifying their supply chains. By sourcing materials globally and establishing production facilities in different regions, manufacturers can mitigate the risks associated with tariffs and offer flexibility to clients seeking sustainable solutions. These proactive measures allow companies to maintain growth momentum, ensuring they remain leaders in the mold stamping sector despite external pressures.

Furthermore, fostering partnerships with local and international stakeholders has enabled Chinese manufacturers to adapt quickly to changing market dynamics. Collaborations with suppliers and customers provide valuable insights into demand patterns and emerging opportunities. This cooperation fuels innovation and fosters a culture of continuous improvement, positioning these companies to not only cope with current challenges but also gear up for future expansion. As a result, the Chinese manufacturing sector is proving that strategic resilience can transform obstacles into opportunities.

In the face of tariff challenges, Chinese manufacturing has not only persisted but has also thrived, largely due to the adoption of advanced technologies that enhance efficiency and precision. The integration of cutting-edge technologies like automation, artificial intelligence, and advanced robotics has transformed traditional manufacturing processes, allowing for smoother operations and reduced labor costs. For instance, manufacturers utilizing smart molds in stamping solutions can achieve higher accuracy and faster production rates, which is essential in a competitive market.

Moreover, technology plays a vital role in supply chain management, enabling real-time tracking and data analytics for inventory and resource optimization. This innovation helps manufacturers to adapt quickly to market demands while maintaining high quality and minimizing waste. As companies increasingly embrace digital transformation, they are not only improving their productivity but also positioning themselves as leaders in the global manufacturing arena. By investing in technology-driven solutions, Chinese manufacturers can effectively navigate tariffs and other challenges, ensuring sustainable growth in an evolving landscape.

This pie chart illustrates the percentage distribution of various advancements contributing to improved manufacturing efficiency in Chinese manufacturing. The data emphasizes the critical role of technology in overcoming tariff challenges.

The landscape of global manufacturing has been significantly transformed by recent economic shifts, with China emerging as a powerhouse despite facing tariff challenges. According to a report by Statista, the global mold and die industry is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026, highlighting a rising demand for advanced manufacturing solutions. This trend is particularly pronounced in sectors like automotive and electronics, where the quality and efficiency of mold stamping solutions can drastically affect production timelines and costs.

Chinese manufacturers have adapted to these market trends by investing in innovative stamping technologies and increasing their focus on quality control. A recent study by Markets and Markets suggests that the Chinese mold market alone is expected to reach $6.6 billion by 2025, driven by advancements in automation and material sciences. As global demand for precision-engineered components increases, Chinese firms are positioning themselves to not only meet local needs but also export their expertise to international markets, transforming potential challenges into opportunities for growth.

This bar chart illustrates the growth in Chinese manufacturing output from 2019 to 2023, highlighting the resilience and expansion of the sector despite ongoing tariff challenges.