In the rapidly evolving landscape of manufacturing and engineering, Wire Cut Wire technology has emerged as a pivotal method for precision cutting of materials such as metals, plastics, and composites. However, the challenges associated with this technology are becoming increasingly evident. According to a recent industry report by MarketsandMarkets, the global wire cut technology market is expected to reach $12 billion by 2025, underscoring its significance in various applications. Despite its advantages in terms of accuracy and efficiency, manufacturers often encounter hurdles such as equipment costs, process complexity, and material compatibility. As industries seek innovative alternatives to enhance productivity and reliability, understanding these challenges becomes crucial. This blog will delve into the complexities surrounding Wire Cut Wire technology and explore viable alternatives that can meet the demands of modern production environments.

Wire Cut Wire Technology, often referred to as wire EDM (Electrical Discharge Machining), is a highly precise machining process widely used in various industries. This technology employs a thin wire as an electrode to cut through materials with exceptional accuracy. One of its primary applications is in the production of intricate shapes and components in sectors such as aerospace, automotive, and medical devices. The precision of wire EDM makes it ideal for creating complex geometries that traditional machining methods struggle to achieve.

In addition to its precision, Wire Cut Wire Technology offers versatility in material selection. It can work effectively with conductive materials, including hardened steel, copper, and aluminum, making it suitable for a wide range of applications. The process also minimizes material waste, as it involves minimal mechanical stress on the workpiece. However, industries must navigate challenges such as slower cutting speeds compared to other machining methods and the need for specialized setup and maintenance. Ensuring optimal operational conditions is crucial to harnessing the full potential of Wire Cut Wire Technology while mitigating these challenges.

Wire Cut Wire Technology has become increasingly popular in various industries due to its precision and efficiency. However, implementing this technology comes with its own set of challenges that can hinder productivity. One of the key challenges is the initial setup and calibration process. A poorly calibrated machine can lead to inconsistent cuts, resulting in wastage and increased costs.

To mitigate this issue, it’s essential to invest time in thorough training for operators. Ensuring that your team understands the machine's functions and how to perform regular maintenance can greatly enhance the reliability of the technology. Additionally, consider establishing a routine check-up schedule to maintain optimal performance.

Another challenge is the material compatibility. Not all materials can be processed effectively with wire cut wire technology, which can complicate project planning. It’s important to conduct material tests prior to the production phase. This will not only streamline the process but also help in selecting suitable materials that work best with the technology, ultimately leading to better outcomes in your projects.

This chart represents the key challenges faced in the implementation of Wire Cut Wire Technology, highlighting the significant impact of each challenge on the overall process.

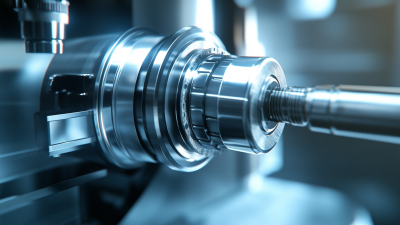

Wire cut technology has gained significant attention as a modern alternative to traditional wire processing techniques. While traditional methods have long been the backbone of wire manipulation, advancements in wire cut technology offer enhanced precision and efficiency in various applications. A recent comparative analysis highlights how wire cut methods, such as wire electrical discharge machining (W-EDM), can provide lower residual stress compared to conventional techniques. This is particularly relevant in industries where the mechanical integrity of components is paramount.

Tip: When considering switching to wire cut technology, focus on optimizing process parameters to minimize defects and enhance performance. Understanding how factors like fiber orientation and machine settings affect the final product can dramatically improve results.

Moreover, studies on the integration of wire-based technologies into additive manufacturing illustrate the potential for greater environmental sustainability. For instance, evaluating the life cycle of wire-based directed energy deposition reveals both economic and ecological benefits. Adopting these contemporary methods can lead to a greener production process, aligning with industry trends pushing for sustainable practices.

Tip: Conduct regular assessments of machining processes to identify bottlenecks and areas for improvement. Engaging with advanced machine learning models for optimization can drive innovation and efficiency in wire cut operations.

In the realm of wire cut wire production, manufacturers often grapple with the delicate balance between cost and quality. Achieving high standards of quality is paramount, especially in applications where precision and performance are critical. However, delivering that quality can significantly increase production costs. This creates a challenging scenario where businesses must weigh the implications of investing in superior materials and advanced technologies against the pressure to minimize expenses.

To manage these trade-offs effectively, companies must adopt a strategic approach to production planning. Investing in high-quality raw materials and state-of-the-art cutting technologies can enhance the final product's performance, leading to higher customer satisfaction and potentially greater market share. Nevertheless, this investment comes with financial risks. Manufacturers need to analyze their target market and competition to understand whether customers are willing to pay a premium for quality, or if a more budget-friendly approach would secure a stronger foothold in the market. By carefully assessing these factors, wire cut wire producers can navigate the complexities of cost versus quality to achieve sustainable growth.

The evolution of wire cut wire technology has sparked significant innovations aimed at addressing its inherent challenges. One notable advancement is the introduction of automated processes that enhance precision and efficiency. These automated systems not only reduce human error but also allow for faster production cycles. As manufacturers strive for higher quality and lower production costs, automation becomes an essential component in streamlining operations and improving the overall output of wire cut parts.

Another promising trend is the integration of advanced materials and coatings. New alloys and treatment processes are being developed to enhance the durability and performance of wire cut products. These innovations are particularly beneficial for industries requiring high-performance materials, such as aerospace and medical devices. Consequently, manufacturers are better equipped to meet stringent industry standards while also fostering sustainability through optimized resource use. As wire cut wire technology continues to advance, the focus will likely remain on enhancing efficiency, product quality, and environmental responsibility, setting the stage for further developments in this critical field.

| Challenge | Impact | Current Innovations | Future Trends |

|---|---|---|---|

| Material limitations | Reduced efficiency and increased production costs | Development of new alloys and composite materials | Adoption of advanced materials for enhanced performance |

| Technology integration | Challenges in incorporating new tech into existing systems | Interoperable systems and modular technology solutions | Full automation and AI integration for efficiency |

| Cost management | Impact on profitability and market competitiveness | Lean manufacturing practices and cost-effective solutions | Emerging market strategies and pricing models |

| Skill shortages | Limited workforce capable of managing new technologies | Training programs and upskilling initiatives | Collaboration with educational institutions for talent development |

| Environmental regulations | Need for compliance can increase operational costs | Eco-friendly processes and sustainable practices | Innovation towards zero-waste technologies |