In the realm of Wire Cutting, the right tools make a significant difference. Renowned expert John Thompson states, "The quality of your wire cutting tools directly impacts your efficiency." His insight resonates deeply in an industry where precision is essential.

Choosing the best wire cutting tools is not just about brand names. It's about understanding your specific needs and the materials you frequently work with. Whether you're a professional electrician or a DIY enthusiast, the right tool can enhance your work quality. However, mistakes happen. Many users have found themselves with tools that simply didn’t meet their expectations.

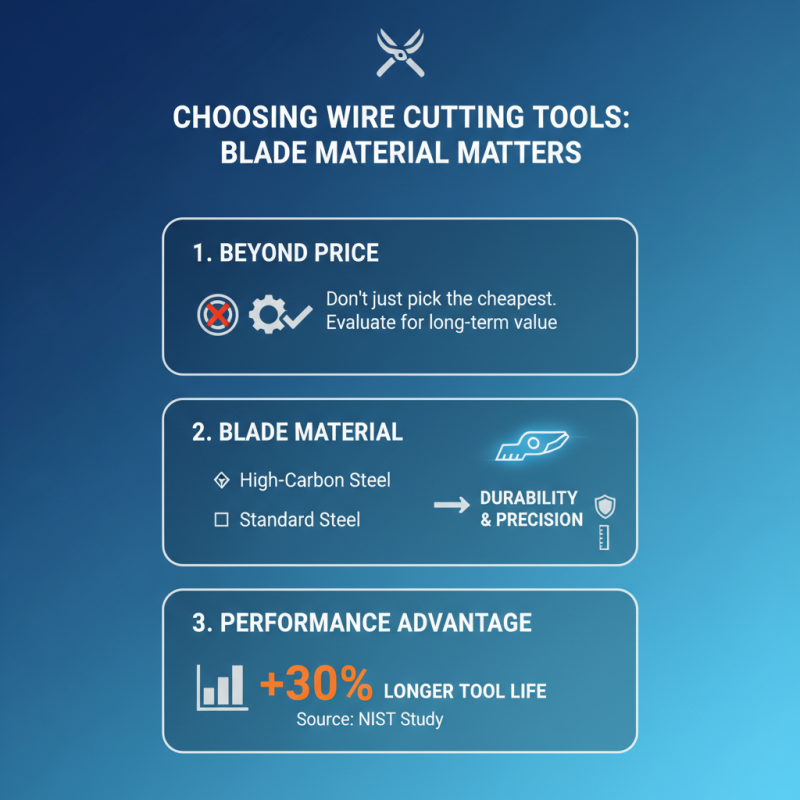

Reflecting on past purchases, some may realize that they prioritized cost over quality. It's easy to be drawn to cheaper options, yet this often leads to frustration. Investing in the best wire cutting tools requires careful thought and consideration. The right choice can lead to substantial time savings and better results in your projects.

Wire cutting tools are essential for various applications, from electrical work to crafting. Understanding their types and uses can significantly enhance your efficiency and safety. The most common types are wire cutters, wire strippers, and cable shears. Each tool has a specific purpose, making it crucial to select the right one for your task.

For instance, wire cutters can handle soft copper wires but struggle with harder alloys. Wire strippers, on the other hand, are designed to remove insulation from wires without damaging the conductor. According to industry reports, using the appropriate tool can increase project efficiency by up to 30%. While each tool has distinct benefits, an inappropriate choice can lead to poor results.

Tip: When selecting a wire cutting tool, consider the materials you will work with. Test different options to find what feels right for you.

Proper handling of these tools is just as vital. Many users overlook the importance of regular maintenance. Dull tools can cause injuries and inaccuracies. Regularly sharpen wire cutters and replace worn wire strippers. Neglecting this aspect can potentially cause delays in your projects.

Tip: Always inspect your tools before use. A quick check can save you from unexpected issues.

Choosing the right wire cutting tools involves more than just picking the cheapest option. When evaluating these tools, consider the blade material. High-carbon steel blades are popular for their durability. They resist wear and offer precise cuts. A study by the National Institute of Standards and Technology highlights that tools with this material last 30% longer than those with standard steel.

Ergonomics should also be a top priority. A comfortable grip can reduce hand fatigue. Research indicates that tools designed with ergonomic factors can decrease user strain by 40%. This means less pain during prolonged use. Additionally, cutting capacity is crucial. Ensure the tool can handle the wire thickness you intend to work with. Mishaps during cutting can lead to injury and waste. Always check specifications carefully. Some tools may not live up to claims.

Lastly, safety features play a significant role. Look for tools with protective guards or features that minimize the risk of accidents. These aspects are often overlooked but can make a significant difference. While the selection seems vast, not all tools meet essential standards. Prioritize quality and safety to avoid purchasing regrets later on.

When it comes to wire cutting tools, the variety is astonishing. Choosing the right one can feel overwhelming. Many users often get confused by the features. Some tools are designed for heavy-duty projects, while others cater to lighter jobs. For instance, a robust wire cutter can slice through thick metal wiring like butter. However, it might not be ideal for delicate tasks.

It's crucial to consider your specific needs. Do you require precision or strength? A wire cutting tool that excels in one area might fail in another. Many users have found that the most expensive tools aren't always the best. Performance varies significantly based on design and intended use. It’s essential to carefully read reviews and compare options.

Some tools may look appealing but lack functionality. A pretty design does not guarantee efficiency. Users often overlook comfort and grip in their buying decisions. This can lead to discomfort during extended projects. Reflecting on these aspects can help improve your buying choices. Take the time to evaluate what really matters to you.

Choosing the right wire cutting tool is essential for any project. Start by considering the material of the wire you will cut. Different tools excel at cutting specific types of wires. For instance, copper wire requires sharp blades. Insulated wire needs tools that can cut without damaging the insulation.

Tips: Always check the tool's specifications. Look for ease of use and comfort. If the handle is uncomfortable, you’ll struggle during lengthy tasks. Sometimes, the most expensive tools are not the best for your work.

Balance weight and size too. A lightweight tool is easier to handle but may lack the durability needed for heavy jobs. Consider how often you’ll use the tool. If it's infrequent, a less expensive option may suffice. But for frequent projects, invest in durability.

Finally, read user reviews about the tools. They often reveal common issues that manufacturers might not highlight. An overlooked tool can make all the difference in your work. Ensure you make an informed decision.

Maintaining your wire cutters is essential for longevity. Regular cleaning is a simple yet effective step. Remove debris after each use. A soft cloth works well for this. Check for rust or corrosion on the blades. These issues can affect performance.

Lubrication is another vital aspect. Use a light machine oil to keep the pivot area functioning smoothly. A few drops are usually sufficient. It’s easy to overlook this, but neglecting lubrication can lead to stiffness over time. Also, store your cutters in a dry place to prevent moisture build-up.

Improper usage can shorten the life of your wire cutters. Avoid cutting materials they aren’t designed for. This mistake can lead to dull blades and misalignment. Inspect your tools regularly. Look for signs of wear and tear, and replace them if necessary. It’s better to address problems early rather than waiting until they worsen.