In any crafting endeavor, precision is crucial. This is especially true when it comes to the art of Wire Cut techniques. The right method can elevate simple materials into stunning designs. Many crafters struggle to achieve consistent results, often questioning their techniques. Common mistakes include using improper tools or not understanding the wire's properties.

Wire Cut techniques require patience and practice. For instance, the angle of the cut can impact the final look. A clean edge can make a difference, yet achieving that can be tricky. Sometimes, we overlook minor details, which lead to unsatisfactory outcomes. It’s essential to reflect on these missteps to improve our skills.

Not every project will turn out as envisioned. Frustration may arise when results deviate from expectations. By analyzing our approach, we gain insights into effective Wire Cut methods. Embracing imperfections is part of the learning journey. Each challenge presents an opportunity to refine our technique and achieve flawless results in future projects.

Wire cutting is a crucial technique in various industries, including manufacturing and arts. Understanding different wire cutting techniques can enhance precision and efficiency in your projects. Reports indicate that improper cutting methods can lead to an increase in material waste by up to 20%. Thus, mastering the right approach is essential for optimal results.

One effective technique is the use of a wire cutter with adjustable tension. This tool allows for consistent cuts, reducing the likelihood of frayed edges. However, it can be challenging to achieve the perfect balance of tension. Experimenting with different settings can sometimes result in unsatisfactory cuts, making it essential to practice and adjust accordingly.

Tips: Always inspect your wire cutter's blade regularly. Dull blades can lead to messy cuts and damaged materials. Consider using a guide for your cuts to enhance accuracy. Another method involves using jigs, but they require careful calibration. If not set correctly, jigs can create uneven lengths, contributing to potential waste.

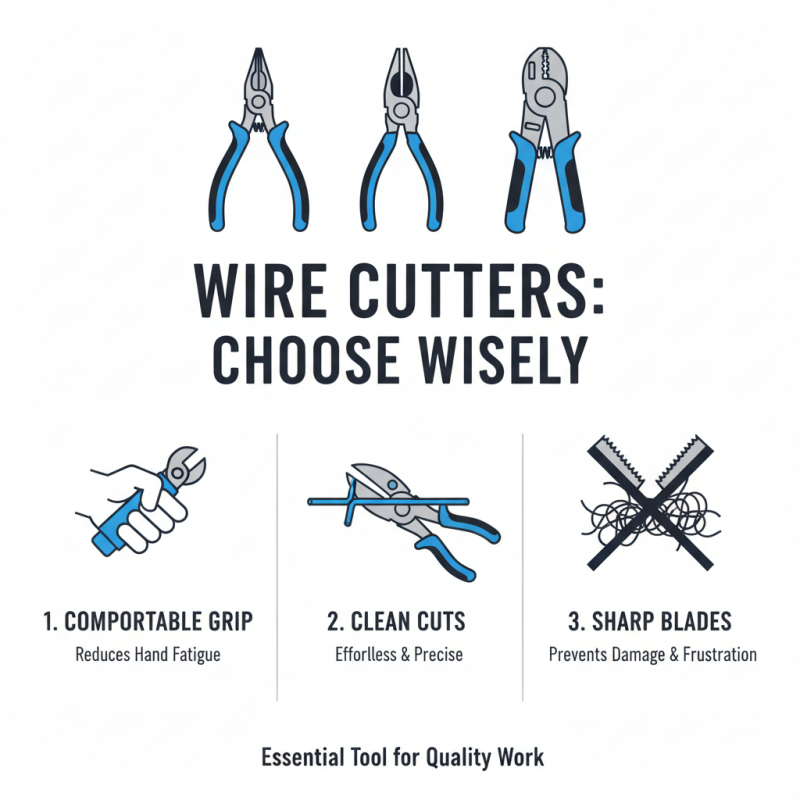

When it comes to wire cutting, having the right tools can make all the difference. A good pair of wire cutters is essential. Look for cutters that feel comfortable in your hand. They should provide a clean cut without excessive force. Dull blades can ruin your work and lead to frustration.

Another important tool is a sturdy pair ofpliers. They help bend and twist wire as needed. Choose pliers that grip well. This ensures better control. Safety goggles are also crucial. Flying wire pieces can cause injuries. It's a small step that goes a long way.

Sometimes, even the best tools can fall short. Misalignment is common, leading to uneven cuts. Practice on scrap wire to improve your skills. Not every piece will turn out perfect. Learn from the mistakes. Each cut is a chance to refine your technique and become more precise.

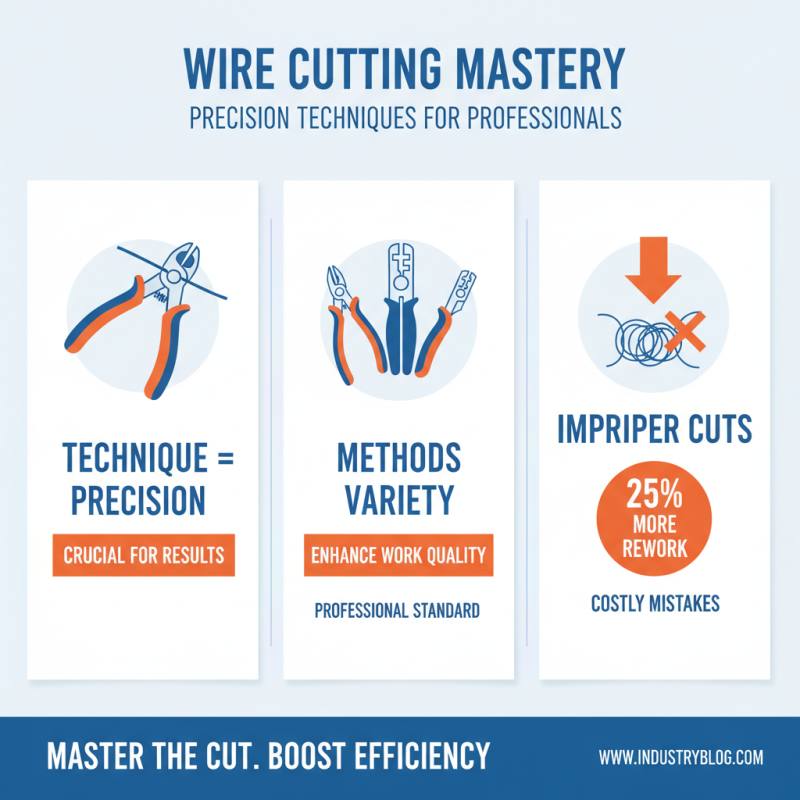

When it comes to wire cutting, technique is crucial for achieving precise outcomes. Many professionals utilize a variety of methods. Understanding these techniques can enhance your work quality. Industry reports indicate that improper cutting can lead to a 25% increase in rework. This alone emphasizes the importance of mastering wire cutting methods.

One common technique is using the flush cut. This method allows for a clean and flat cut. It minimizes sharp edges, which is especially useful when working with delicate materials. However, it requires consistent pressure and steady hands. For beginners, this might feel intimidating. Remember, practice is vital. Don't be afraid to make mistakes; they can be your best teachers.

Tip: Always keep your tools sharp. Dull tools can mess up your cuts and create a safety hazard. Another technique is the angled cut. This allows for better access in tight spaces. But be aware; an angled cut can be more challenging to execute accurately. Reflect on your approach. Are you rushing? Take your time to ensure precision. Each method requires patience and skill, so embrace the learning process to refine your cutting abilities.

Wire cutting can be challenging. Many people make common mistakes that can lead to poor results. A report from the International Wire Cutting Association found that nearly 40% of professionals experienced issues due to improper technique. This can include using the wrong angle when cutting or applying excessive force.

One significant mistake is failing to measure accurately. A slight miscalculation can result in material wastage. According to a survey, 70% of error cases arise from inadequate measurement practices. Additionally, not maintaining the wire cutting tools can also lead to unsatisfactory outcomes. Dull blades or misaligned cutters can create uneven edges, which may compromise the final project.

Another overlooked aspect is the selection of the right cutting technique. Each wire type demands a specific approach. For instance, a thicker gauge might require slower speeds and steadier hands. On the contrary, fine wires can be more fragile and need gentle handling. Ignoring these details often results in frustration and wasted materials. It's essential to learn from mistakes and refine one’s technique for better precision.

This bar chart illustrates the success rates of different wire cutting techniques. Technique A shows the highest success rate, suggesting it may be the most effective method, while Technique D has the lowest performance, indicating that caution should be taken to avoid errors associated with it.

When it comes to wire cutting, precision is key. Achieving perfect wire cuts can greatly impact the final result of any project. According to industry reports, companies utilize wire cutting techniques that improve efficiency by up to 40%. However, achieving this level of precision requires attention to detail and proper technique.

One common tip is to ensure your cutting tool is sharp and well-maintained. A dull blade can create jagged edges, leading to further issues. Additionally, consider the gauge of the wire. Thicker wires may require different techniques compared to thinner ones. For example, using a steady pressure can yield cleaner cuts. It may take practice to find the right pressure for each wire type.

Moreover, lighting plays a vital role. Poor lighting can lead to misalignment, ruining an otherwise perfect cut. Ensuring a well-lit workspace is crucial. Remember, even small distractions can lead to imperfections in your work. Evaluating your setup regularly can help identify areas for improvement. Fine-tuning these elements can significantly elevate your wire-cutting skills.

| Technique | Description | Precautions | Best For |

|---|---|---|---|

| Flush Cutting | Cuts wire close to the surface for a clean finish. | Use a steady hand to avoid jagged cuts. | Jewelry making, arts and crafts. |

| Diagonal Cutting | Cuts at an angle, ideal for thicker wires. | Ensure the wire is securely held. | Electrical work, HVAC applications. |

| Coping Technique | Follows the natural curve of the wire for smooth cuts. | Requires practice for best results. | Advanced craft projects, model building. |

| Score and Snap | Score the wire for a clean break. | Be aware of sharp edges after breaking. | Metal fabrication, structural work. |

| Twisting Technique | Twists wire together for a secure hold. | Do not over-twist as it can weaken the wire. | Electrical connections, crafting. |