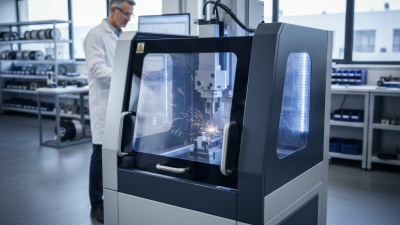

In recent years, Small Wire Edm has gained popularity in various manufacturing sectors. This technique allows for precision machining of intricate designs. Manufacturers are increasingly turning to Small Wire Edm for its ability to create detailed parts efficiently.

The advancements in Small Wire Edm technologies have led to innovative methods that enhance productivity. New wire materials and improved guiding systems are key to achieving better accuracy. However, there are still challenges faced by technicians. For example, wire breakage can lead to costly downtimes. Continuous improvement in techniques is essential to address these issues.

As we look toward 2026, the landscape of Small Wire Edm continues to evolve. Insights into effective techniques and emerging innovations will guide manufacturers. Exploring these advancements could pave the way for more efficient production processes. However, it is crucial to remain aware of the limitations in current methods. Frequent reflection on these aspects will ensure the growth and effectiveness of Small Wire Edm in the future.

Small wire EDM technology is rapidly evolving, with significant enhancements on the horizon for 2026. One notable trend is the development of more efficient power supply systems. These systems promise to increase cutting speed while reducing energy consumption. Cutting-edge research is tackling better pulse control, which can improve accuracy. This can lead to cleaner cuts and less material waste.

Another intriguing innovation involves automation in the small wire EDM process. Advanced robotics are merging with intelligent software, allowing for real-time adjustments during machining. This can minimize human error and speed up production times. However, integrating these technologies presents challenges. Operators may find it difficult to adapt to new systems. Training is crucial, and businesses must invest in ongoing education.

Finally, there’s a shift toward eco-friendly practices in the small wire EDM industry. Companies are exploring biodegradable dielectrics and recyclable materials. This is a positive movement, but it requires careful consideration of performance. Can eco-friendly options match the precision of their traditional counterparts? These are questions that need reflection as the industry pushes forward. The future holds promise, yet there are hurdles to overcome.

As we look into 2026, wire electric discharge machining (EDM) shows promising innovations. One critical area is the exploration of advanced wire materials. These materials have the potential to enhance performance, efficiency, and precision in EDM processes. A variety of new alloys and coatings have been developed. They offer improved conductivity and resistance to wear, which is vital for consistent results.

Wire materials like Copper and Brass have long been used. Yet, researchers are experimenting with hybrid composites. These combinations could resolve some performance issues. However, the effectiveness of these new materials remains under evaluation. Many practitioners report mixed results. Some materials work well in certain applications but not in others.

It's essential to examine these innovations critically. Some solutions may not deliver the anticipated benefits in real-world scenarios. The reliance on cutting-edge technology could lead to unexpected challenges. Users must remain aware of the limitations. As these innovations roll out, ongoing assessment and feedback will be vital for understanding their true impact on EDM performance.

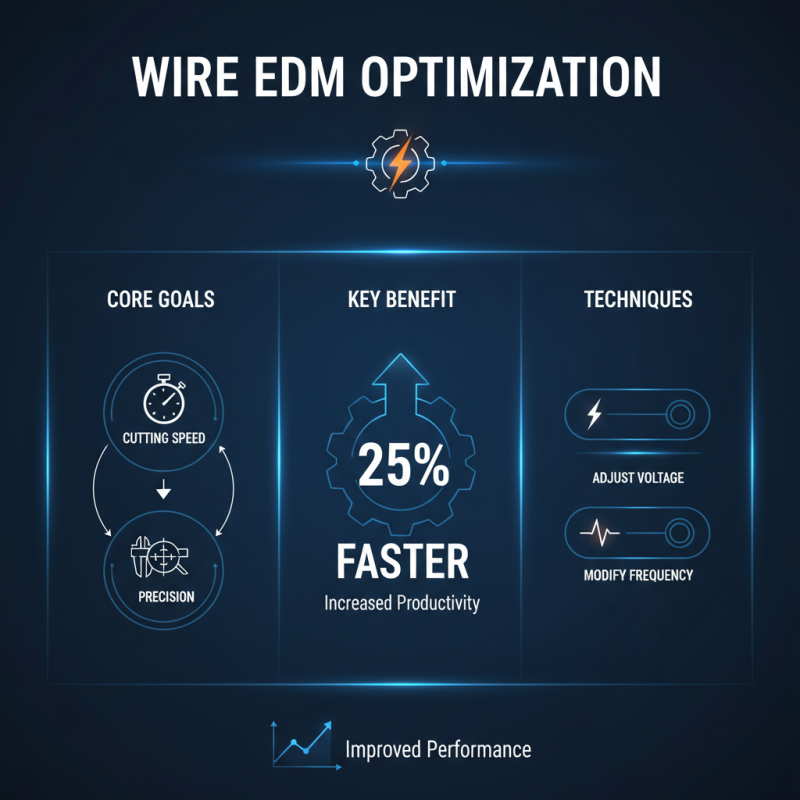

In the rapidly evolving field of wire EDM (Electrical Discharge Machining), optimization techniques have become critical. Cutting speed and precision are paramount for engineers. Recent reports indicate that optimizing machining parameters can improve cutting speed by up to 25%. This is substantial for manufacturers aiming to enhance productivity. Techniques such as adjusting voltage and frequency play vital roles here.

Applying advanced software solutions can also significantly influence outcomes. Studies have shown that simulations can reduce setup time by 30%. Yet, not all processes yield consistent results. Variability in materials and environmental conditions can affect precision. There remains an opportunity for further research in this area.

Moreover, integrating real-time data analysis can provide insights into machining performance. Continuous monitoring can reveal potential issues before they escalate. However, implementing such systems might require upfront investment and training. This presents a challenge for smaller operations. Balancing cost and innovation is complex but necessary for long-term success.

In recent years, small wire EDM has gained traction in various industries.

Case studies highlight remarkable implementations of innovations.

For example, a precision machining company in the aerospace sector adopted small wire EDM techniques to produce

intricate components. This led to a 30% reduction in production time

and a 25% increase in accuracy.

Another case involved a medical device manufacturer. This company reported a 15% cost reduction

after integrating advanced wire EDM technology. The ability to work with hard-to-machine materials

was a game-changer. However, some engineers noted challenges in setup times, which can hinder efficiency initially.

Tips: Focus on training your operators. A well-trained team can minimize the learning curve associated with new technologies.

Moreover, regularly assess your wire EDM machines for maintenance. This prevents downtime and maintains precision.

It's crucial to reflect on the overall integration process. Some shops experienced delays due to underestimating setup complexity.

Learning from these experiences can help others avoid similar pitfalls. The data reveals that proper planning

significantly impacts the success of small wire EDM innovations.

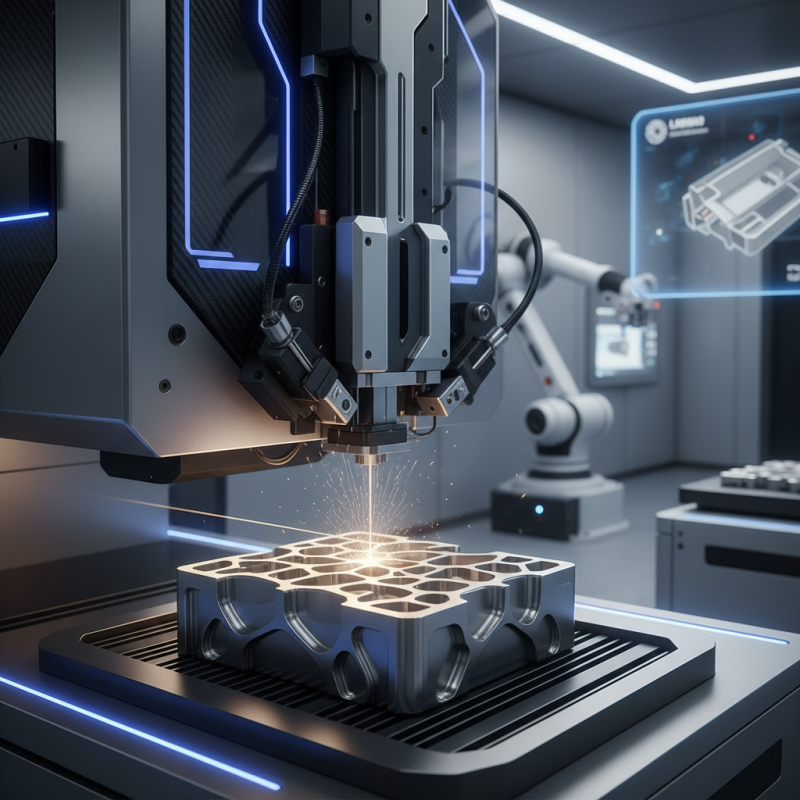

The role of AI and automation in the wire EDM process is rapidly evolving. These technologies promise significant enhancements. AI can analyze data from the machining process in real time. This allows adjustments that improve precision and efficiency. Automation reduces the need for manual labor. Machines can operate continuously, which boosts productivity.

However, there are challenges. Not all wire EDM processes can be easily automated. Some intricate designs may require human oversight. AI systems are only as good as the data fed into them. Poor data can lead to flawed outcomes. Also, there’s a learning curve for operators.

The integration of AI might require rethinking traditional methods. Adapting to these changes can be daunting. Not every shop is ready for such innovations. Training is essential to bridge this gap. As the industry progresses, embracing AI could define a shop’s success. Nevertheless, it demands careful implementation and a dedication to continuous learning.